-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 22. 2025, 13:08:59

In the fast-paced electronics industry, where product lifecycles are shrinking and market competition is intensifying, the ability to bring new products to market quickly has become a decisive competitive advantage. For businesses developing flexible electronic devices, Quick Turn FPCB Assembly Service emerges as a critical enabler, bridging the gap between design validation and mass production with efficient, timely assembly solutions. This specialized service not only shortens lead times but also ensures that flexible printed circuit boards (FPCBs) meet the rigorous performance requirements of diverse applications, from consumer gadgets to medical devices and automotive electronics.

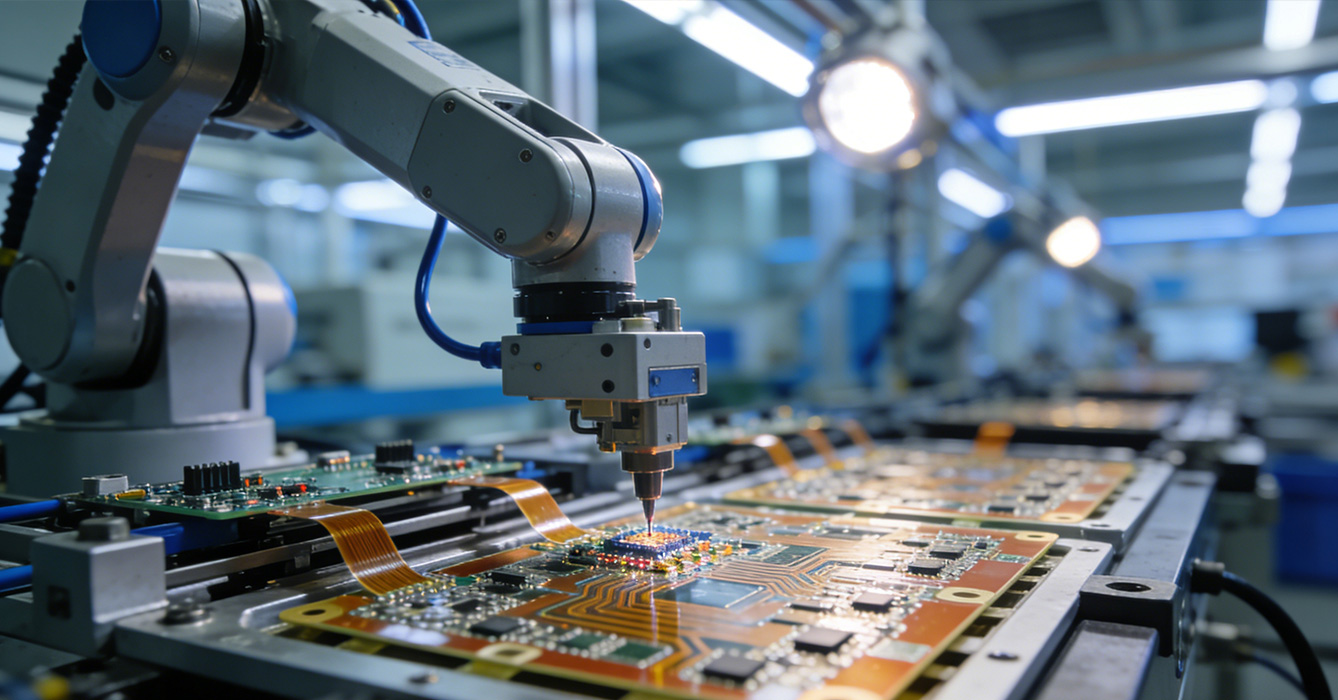

The traditional FPCB assembly process often takes weeks, a timeline that is no longer feasible in an era where consumers demand constant innovation and businesses strive to be first to market. Quick Turn FPCB Assembly Service addresses this pain point by streamlining workflows, leveraging advanced automation, and optimizing supply chain coordination to deliver assembled FPCBs in significantly shorter periods. For startups and small-to-medium enterprises (SMEs), this speed is particularly valuable, as it allows them to test prototypes rapidly, iterate on design feedback, and avoid missing critical market windows.

Beyond speed, Quick Turn FPCB Assembly Service also enhances project flexibility. Unexpected design tweaks, urgent production shortages, or last-minute trade show demo requirements are common in electronics development. A reliable quick-turn service provider can adapt to these changes, ensuring that assembly processes adjust seamlessly without compromising on schedule or quality. This agility is essential for businesses to navigate the uncertainties of product development and maintain a competitive edge.

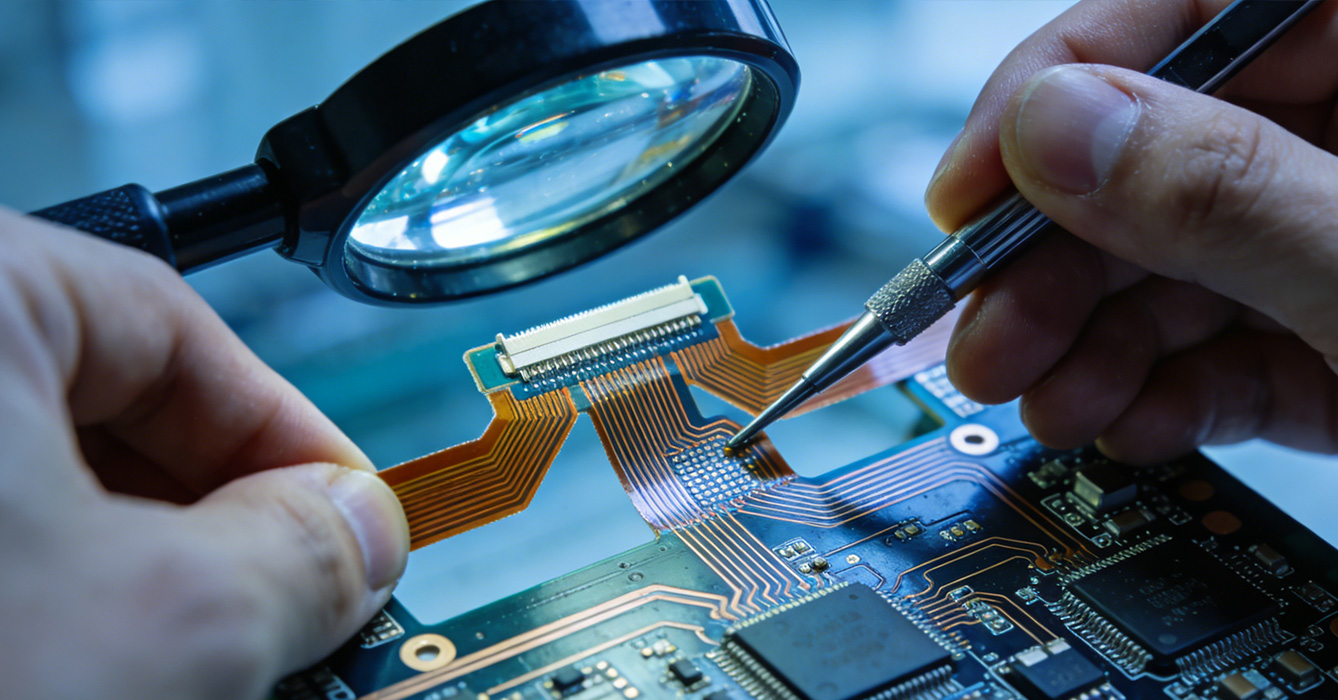

Critics may assume that quick turn-around times come at the cost of quality, but leading Quick Turn FPCB Assembly Service providers disprove this by integrating rigorous quality control measures into every stage of the assembly process. FPCBs are inherently delicate due to their flexible substrates, requiring specialized handling to avoid damage during assembly. Reputable service providers use precision equipment designed for flexible substrates, such as advanced visual positioning systems to ensure accurate component placement and controlled-temperature soldering processes to protect the FPCB’s integrity.

Pre-assembly preparation is another key quality checkpoint. This includes thorough cleaning of FPCB surfaces to remove contaminants that could affect solder adhesion, as well as pre-treatment of pads to enhance conductivity and prevent oxidation. Post-assembly, comprehensive testing—such as automated optical inspection (AOI) for solder defects and electrical performance checks—ensures that every assembled FPCB meets industry standards. By combining streamlined processes with strict quality protocols, Quick Turn FPCB Assembly Service delivers both speed and reliability.

The versatility of Quick Turn FPCB Assembly Service makes it invaluable across a wide range of industries, each with unique assembly needs and time-sensitive requirements. In the consumer electronics sector, it enables the rapid prototyping and production of foldable smartphones, wearable fitness trackers, and wireless earbuds—products where sleek design and quick market entry are paramount. For these devices, FPCBs must be assembled with precision to fit into compact, curved form factors, and quick-turn services ensure that production can keep pace with consumer demand.

The medical device industry also benefits greatly from Quick Turn FPCB Assembly Service. Devices such as portable diagnostic tools and wearable health monitors rely on FPCBs for their miniaturization and flexibility. In emergency medical scenarios or when responding to public health crises, the ability to quickly assemble and deploy these devices can be life-saving. Similarly, the automotive industry uses quick-turn FPCB assembly for urgent repairs or upgrades to advanced driver-assistance systems (ADAS) and electric vehicle components, minimizing production line downtime.

Not all Quick Turn FPCB Assembly Service providers are created equal, and selecting the right partner is crucial for project success. First and foremost, evaluate the provider’s response time and lead time guarantees—look for clear commitments to quick delivery without vague exceptions. Technical capability is also essential: the provider should have experience handling the specific type of FPCB (such as those for high-vibration or high-temperature environments) and the components relevant to your application.

Communication and collaboration are additional critical factors. A reliable service provider will maintain open lines of communication, providing regular updates on assembly progress and addressing any design or technical issues promptly. They should also offer technical support, such as advising on design for manufacturability (DFM) to optimize the FPCB for quick assembly without sacrificing performance. Finally, verify the provider’s quality certifications and testing processes to ensure that their quick-turn services meet your industry’s regulatory requirements.

In conclusion, Quick Turn FPCB Assembly Service has become a cornerstone of modern electronics development, enabling businesses to accelerate time-to-market, adapt to changing requirements, and maintain quality standards. As the demand for flexible, compact electronic devices continues to grow, the role of quick-turn assembly services will only become more vital. By choosing a reputable provider that balances speed, quality, and technical expertise, businesses can unlock the full potential of their FPCB designs and gain a competitive edge in today’s dynamic electronics market.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB