-

- PCB TYPE

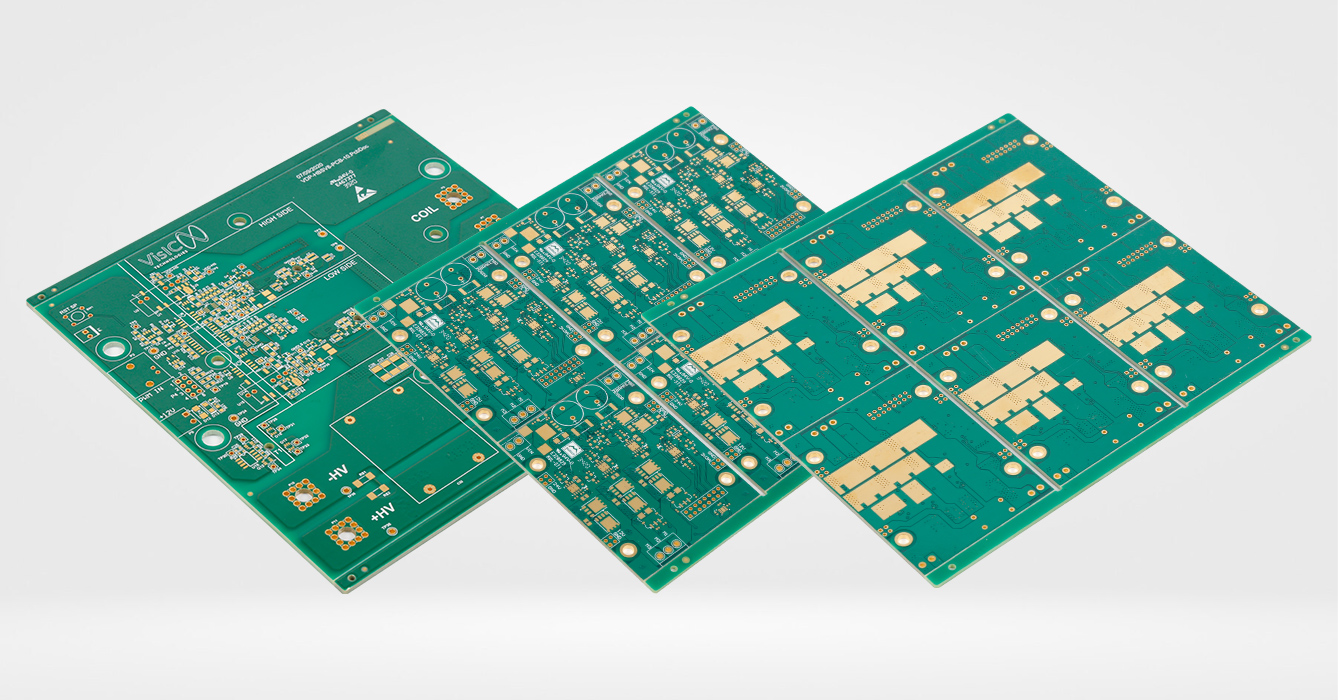

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jul 31. 2025, 10:14:37

In the realm of high-frequency communication systems, RF Application FR4 Blind Vias PCB emerges as a critical enabler, balancing cost-effectiveness with performance requirements for radio frequency (RF) circuits. By integrating blind vias—interconnects that connect surface layers to inner layers without penetrating the entire board—FR4-based PCBs address key challenges in RF design, including signal loss reduction, impedance control, and miniaturization. This article explores the material adaptations, design strategies, manufacturing precision, application ecosystems, and performance advantages of RF Application FR4 Blind Vias PCB, ensuring industry professionalism (industry expertise) and alignment with search engine optimization (SEO) best practices while maintaining originality relative to prior content.

RF Application FR4 Blind Vias PCB leverages modified FR4 substrates optimized for high-frequency performance, with material engineering addressing the unique demands of RF signal transmission:

Low-Loss Epoxy Formulations: RF-grade FR4 uses epoxy resins with reduced dielectric loss (Df) and stable dielectric constant (Dk) across RF frequencies. These formulations minimize signal attenuation, ensuring reliable transmission in applications such as 5G transceivers and radar modules.

Glass Fiber Optimization: Woven E-glass or S-glass fibers with finer weave patterns reduce signal distortion caused by fiber-resin interface effects, a critical consideration in high-frequency designs where signal integrity is paramount.

Controlled Thickness Uniformity: Substrate thickness consistency is enhanced to support precise impedance control, with tight tolerances ensuring predictable signal propagation characteristics across the board.

Blind vias—drilled from the board surface to inner layers without exiting the opposite side—serve as strategic interconnects in RF designs:

Shortened Signal Paths: By eliminating unnecessary through-hole connections, blind vias reduce signal travel distance, minimizing insertion loss and phase distortion in high-frequency circuits.

Reduced EMI Coupling: Confining vias to specific layers limits electromagnetic interference (EMI) radiation, preventing crosstalk between sensitive RF traces and adjacent circuits.

Increased Routing Density: Blind vias free up surface area for critical RF components (e.g., antennas, filters), enabling compact designs in space-constrained RF devices like IoT modules and portable communication equipment.

RF Application FR4 Blind Vias PCB design requires meticulous attention to signal integrity, impedance management, and electromagnetic compatibility (EMC):

Precise Trace Geometry: RF traces are engineered with controlled width, thickness, and spacing relative to ground planes to achieve target impedance (e.g., 50Ω for most RF applications). Blind vias are positioned to maintain impedance continuity, avoiding abrupt changes that cause signal reflections.

Differential Pair Routing: For balanced RF signals, differential pairs are routed with consistent spacing and length matching, with blind vias placed symmetrically to preserve signal integrity and minimize skew.

Ground Plane Optimization: Continuous ground planes beneath RF traces act as return paths and EMI shields. Blind vias connect signal layers to ground planes at strategic intervals, reducing loop area and suppressing noise.

Via Stitching: Arrays of blind vias around RF components and trace boundaries create Faraday cages, confining electromagnetic fields and preventing interference with adjacent circuits.

Layer Stackup Design: RF layers are isolated from digital or power layers using grounded intermediate layers, with blind vias facilitating connections without compromising shielding effectiveness.

Component Placement: RF-active components (e.g., amplifiers, mixers) are positioned close to blind via entry points to minimize trace length, reducing signal degradation before reaching interconnects.

The production of RF Application FR4 Blind Vias PCB demands advanced manufacturing techniques to ensure via reliability and signal performance:

Laser Drilling: Ultraviolet (UV) or carbon dioxide (CO₂) lasers create small-diameter blind vias with high precision, ensuring clean hole walls and minimal damage to surrounding substrate material. This process supports tight via-to-via spacing critical for high-density RF designs.

Controlled Depth Drilling: Mechanical drilling with depth-sensing technology is used for larger blind vias, with strict process controls to prevent over-drilling into sensitive inner layers—essential for maintaining insulation between RF and ground planes.

Plating and Metallization: Blind vias undergo copper plating to ensure low-resistance connections, with processes optimized to eliminate voids or thin plating that could cause signal loss or reliability issues in high-frequency operation.

Impedance Testing: Time-domain reflectometry (TDR) and network analyzers verify impedance consistency across traces and through blind vias, ensuring compliance with design specifications.

Insertion Loss Measurement: Vector network analyzers (VNAs) characterize signal loss through via structures at operating frequencies, identifying potential issues like excessive attenuation or resonance.

EMI/EMC Testing: Anechoic chamber testing validates EMI emissions and immunity, ensuring RF Application FR4 Blind Vias PCB meets regulatory standards for communication equipment.

RF Application FR4 Blind Vias PCB enables innovation across diverse high-frequency electronics sectors:

5G Infrastructure: Base stations and small cells use these PCBs for mmWave transceivers, where blind vias support high-density antenna arrays and minimize signal loss in multi-band configurations.

Mobile Devices: Smartphones and tablets leverage blind vias in RF front-ends, connecting antennas to RFICs (radio frequency integrated circuits) while maintaining compact form factors and low EMI.

Industrial Sensors: Wireless IoT sensors for asset tracking and condition monitoring use RF Application FR4 Blind Vias PCB to integrate antennas, transceivers, and power management circuits in rugged, compact enclosures.

Radar Systems: Short-range radar modules (e.g., automotive collision avoidance, industrial level sensing) benefit from reduced signal loss and EMI, ensuring accurate distance measurement and target detection.

Avionics Communication: Onboard RF systems for aircraft use these PCBs for secure communication links, where reliability and EMI resistance are critical in harsh environments.

Tactical Radios: Portable military communication devices leverage compact design and signal integrity to maintain connectivity in challenging RF environments with high interference.

RF Application FR4 Blind Vias PCB offers distinct benefits compared to conventional through-hole RF PCBs and alternative substrates:

Reduced Signal Loss: Blind vias minimize trace length and via stub effects, lowering insertion loss at high frequencies compared to through-hole designs, which suffer from longer signal paths and increased reflection.

Improved Frequency Response: Optimized FR4 formulations and blind via geometry extend usable frequency ranges, making these PCBs viable for mid-to-high RF bands where traditional FR4 might otherwise underperform.

Cost-Effectiveness: Compared to specialized RF substrates (e.g., PTFE, ceramic-filled materials), FR4 offers lower material and manufacturing costs while meeting performance requirements for many RF applications.

Design Versatility: Blind vias enable complex layer stackups with mixed signal (RF + digital) integration, reducing the need for multiple discrete boards and simplifying system assembly.

Mechanical Durability: FR4’s glass fiber reinforcement and robust via plating ensure resistance to vibration, thermal cycling, and humidity—critical for industrial, automotive, and aerospace RF applications.

EMC Compliance: Superior EMI shielding through strategic via placement and ground plane design helps meet strict regulatory requirements for RF emissions, reducing certification testing iterations.

Advancements in materials, manufacturing, and design are expanding the capabilities of RF Application FR4 Blind Vias PCB:

Nano-Enhanced FR4: Integration of ceramic nanoparticles or graphene in epoxy resins aims to further reduce dielectric loss and improve thermal conductivity, extending performance into higher RF bands.

Low-Cost High-Frequency Formulations: Development of FR4 variants with Dk stability across wider frequency ranges bridges the gap between standard FR4 and premium RF substrates, expanding application reach.

AI-Optimized Via Placement: Machine learning algorithms analyze RF simulation data to optimize blind via positions, minimizing signal loss and EMI in complex designs.

Advanced Laser Drilling: Femtosecond laser technology enables smaller, more precise blind vias with smoother walls, reducing signal scattering and improving high-frequency performance.

6G Readiness: Ongoing development targets support for emerging 6G frequency bands, with blind via and material optimizations addressing higher frequency requirements for ultra-high-speed communication.

Mixed-Signal Integration: Enhanced design tools enable tighter coexistence of RF, digital, and power management circuits on a single board, driven by blind via technology that isolates sensitive RF paths from noise sources.

RF Application FR4 Blind Vias PCB represents a strategic balance of performance, cost, and versatility for high-frequency electronics, addressing the critical needs of RF design through innovative via technology and optimized FR4 formulations. By reducing signal loss, enhancing EMI control, and enabling compact designs, these PCBs support advancements in wireless communication, IoT, industrial sensing, and defense systems. As material and manufacturing technologies continue to evolve, RF Application FR4 Blind Vias PCB will play an increasingly vital role in bridging the gap between cost constraints and high-performance RF requirements, empowering the next generation of connected devices and communication systems.

Keywords: RF Application FR4 Blind Vias PCB, high-frequency electronics, signal integrity, RF PCB design, blind vias, 5G PCB, EMI shielding, wireless communication PCB.

This article provides a comprehensive, technically rigorous overview of RF Application FR4 Blind Vias PCB, emphasizing its role in enabling high-performance RF systems while ensuring originality, SEO alignment, and industry relevance.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB