-

- PCB TYPE

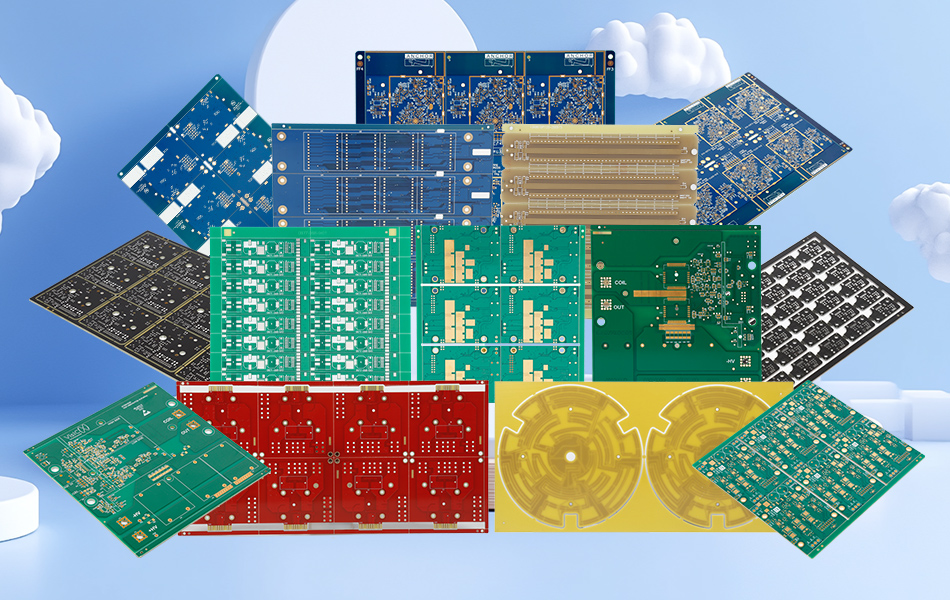

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 13. 2025, 10:45:13

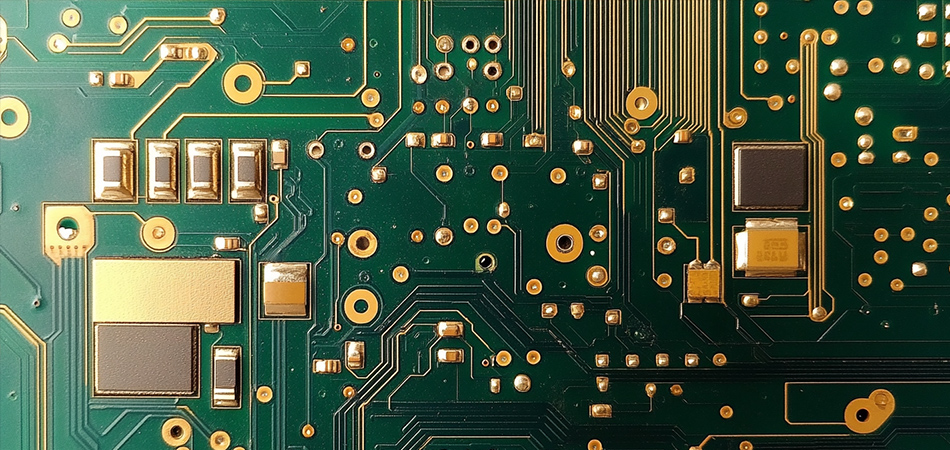

In the fast-paced world of electronics development, Rigid FR4 PCB Prototype Service serves as a critical bridge between design concepts and mass production, enabling engineers and innovators to test, refine, and validate their ideas before full-scale manufacturing. Rigid FR4, with its exceptional balance of mechanical stability, electrical insulation, and cost-effectiveness, remains the material of choice for prototyping most electronic devices. Unlike specialized prototype services for niche materials, rigid FR4 PCB prototype services leverage the ubiquity and reliability of FR4 to offer accessible, fast, and accurate prototypes that closely mimic production-grade boards. This article explores the role of rigid FR4 PCB prototype services in the product development lifecycle, their key features, benefits for designers, and how to select the right service provider, highlighting their indispensable contribution to accelerating innovation in electronics.

A Rigid FR4 PCB Prototype Service specializes in producing small quantities of rigid printed circuit boards using FR4 material, tailored to a designer’s specific schematic and layout. These prototypes are not mere approximations but functional, testable versions of the final product, designed to validate design decisions, identify flaws, and ensure compatibility with components and manufacturing processes.

Rigid FR4 is chosen for prototyping because it closely matches the material properties of production PCBs, ensuring that test results are reliable and scalable. Unlike flexible substrates or specialized high-frequency materials, FR4’s consistent performance across temperature, humidity, and mechanical stress makes it ideal for verifying the functionality of most electronic designs, from simple consumer gadgets to complex industrial controllers.

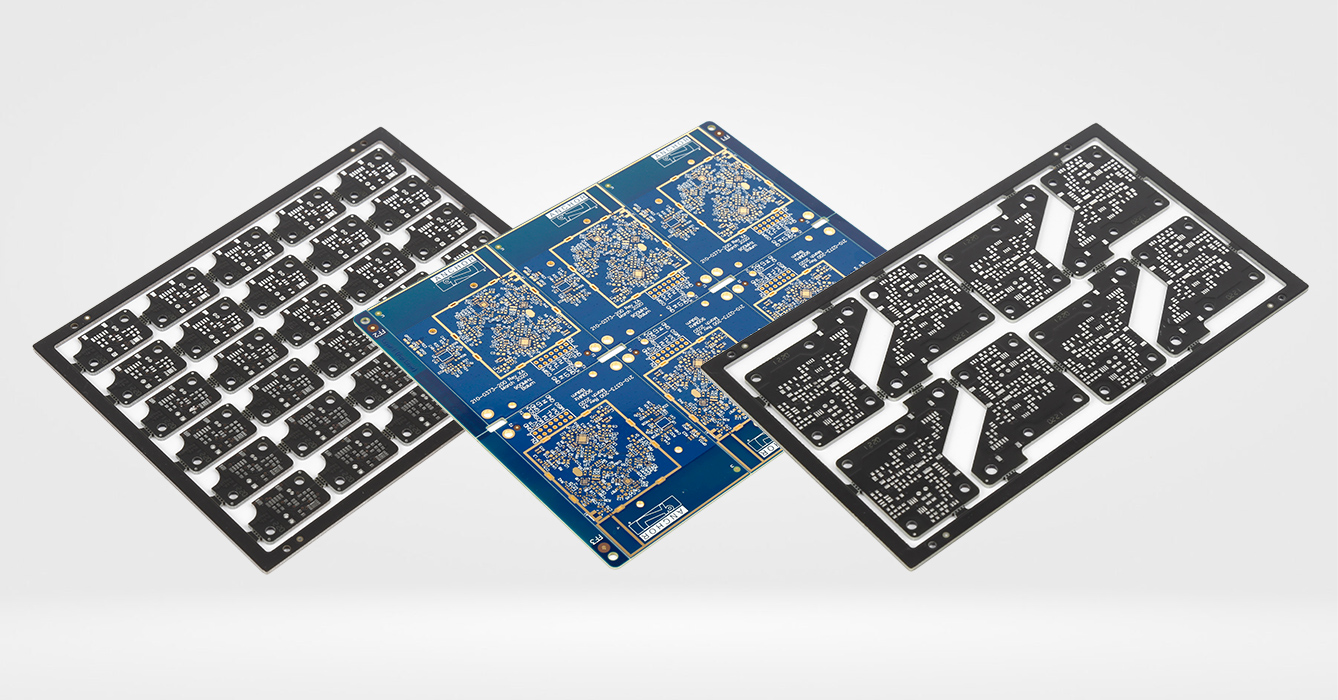

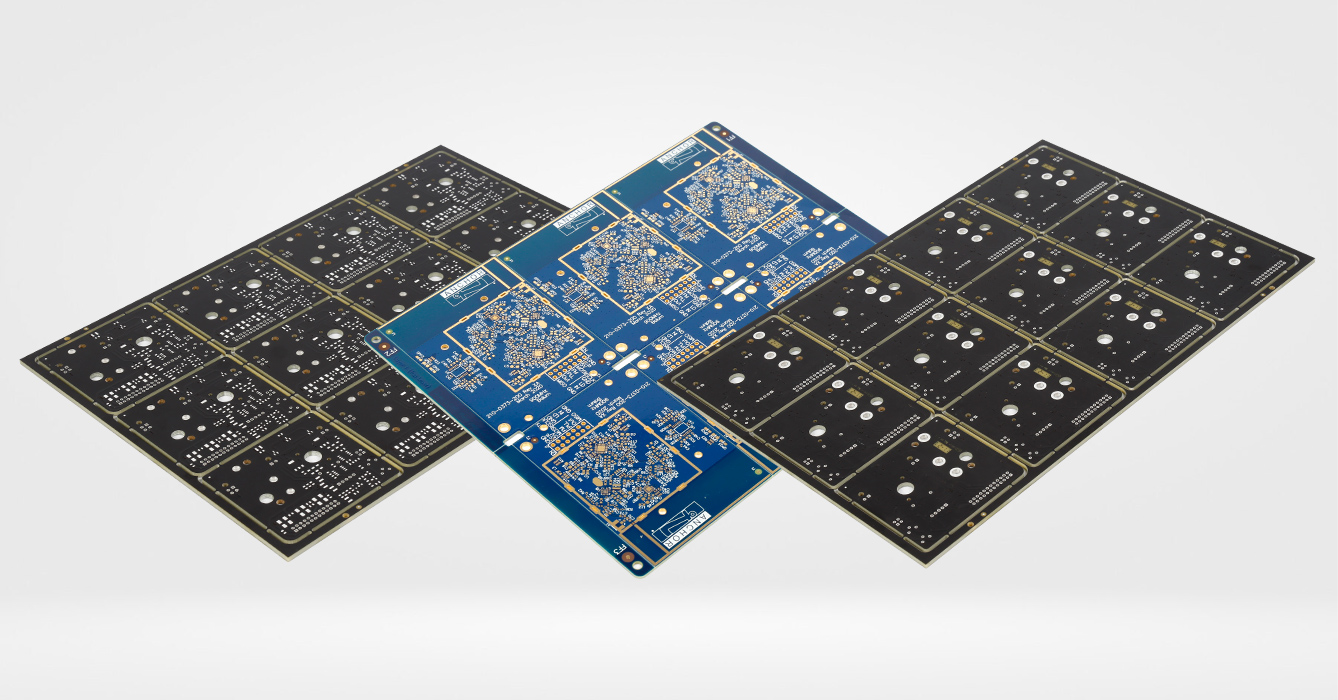

Prototype services for rigid FR4 PCBs typically handle low-volume orders (ranging from a single board to a few hundred), offering customization options such as layer count, copper thickness, and surface finishes to match the intended production specifications. This flexibility allows designers to iterate quickly, making adjustments based on prototype testing without committing to large-scale manufacturing.

Rigid FR4 PCB prototype services are integral to every stage of electronic product development, from concept to production:

In the early stages of design, a prototype helps confirm that the circuit layout works as intended. Engineers can test basic functionality, such as signal flow, power distribution, and component compatibility, ensuring that the design meets core requirements before investing in more detailed development.

No design is perfect on the first try. Prototypes reveal issues like short circuits, impedance mismatches, or thermal hotspots that may not appear in simulations. Rigid FR4 prototypes allow designers to modify traces, adjust component placement, or revise layer stacks, iterating until the design is optimized.

Rigid FR4 prototypes are subjected to rigorous testing, including thermal cycling, vibration resistance, and electrical stress tests, to ensure they meet performance standards. These tests are critical for applications like automotive or industrial electronics, where reliability is paramount.

Prototyping helps identify potential manufacturing challenges, such as difficult-to-drill via patterns or incompatible surface finishes. By working with a prototype service, designers can adjust their layouts to align with production capabilities, reducing costly rework during mass manufacturing.

Functional prototypes allow designers to showcase their vision to stakeholders, investors, or clients, providing tangible evidence of a product’s potential. This is especially valuable in securing funding or approvals for further development.

In each of these stages, rigid FR4 PCB prototypes serve as a practical, cost-effective tool for reducing risk and ensuring that the final product meets all technical and commercial requirements.

To meet the diverse needs of designers, rigid FR4 PCB prototype services offer a range of features that balance speed, accuracy, and customization:

Time is critical in product development, so prototype services prioritize quick delivery. Many providers offer turnaround times of 24–72 hours for simple designs (e.g., 2–4 layer boards), with more complex prototypes (e.g., 10+ layers) typically delivered within a week. This speed allows designers to iterate rapidly, keeping projects on schedule.

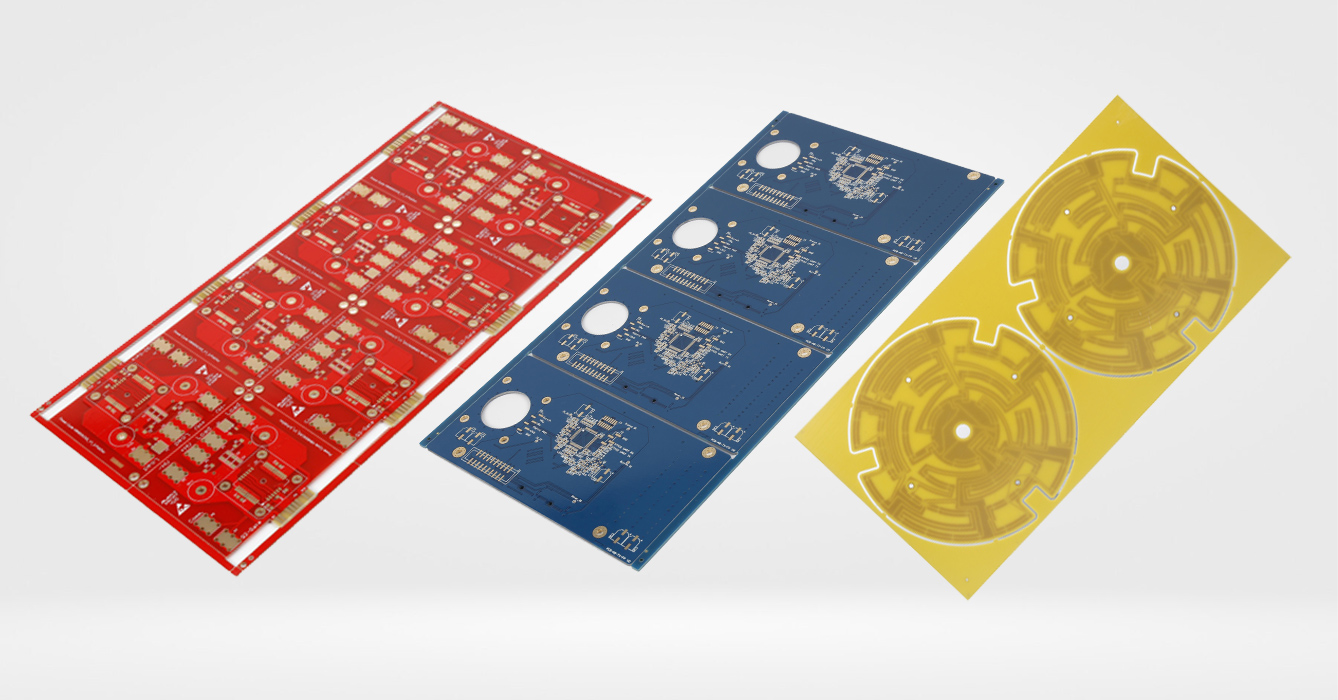

Prototype services accommodate a variety of design specifications, including:

Layer count: From single-layer to multi-layer (up to 20+ layers) for complex designs.

Copper thickness: Adjusting based on current-carrying requirements, from thin (for signal traces) to thick (for power circuits).

Surface finishes: Options like HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), or OSP (Organic Solderability Preservative) to match production plans.

Solder mask and silkscreen: Custom colors and legends for clarity and branding.

These options ensure that the prototype closely mirrors the intended production board, making test results more reliable.

Design for Manufacturability (DFM) Checks

Reputable prototype services include DFM checks as part of their offering, reviewing designs for potential issues like trace width violations, via placement errors, or incompatible material choices. This proactive feedback helps designers correct flaws before manufacturing, reducing delays and costs.

Even for prototypes, quality is essential. Services use automated optical inspection (AOI) and electrical testing (e.g., flying probe testing) to verify that each board meets specifications, ensuring that prototypes are functional and accurate representations of the design.

Prototype services use high-quality FR4 laminates that match industry standards, ensuring that the prototype’s mechanical and electrical properties align with production-grade materials. This consistency is critical for reliable testing, as material variations can skew results.

Designers and businesses gain numerous advantages by leveraging professional rigid FR4 PCB prototype services:

Prototyping with FR4 is significantly cheaper than using specialized materials, and low-volume orders reduce waste compared to full production runs. Identifying design flaws early also avoids costly rework during mass manufacturing, where even minor changes can incur substantial expenses.

Fast turnaround times and iterative testing allow products to move from concept to production more quickly, giving businesses a competitive edge in crowded markets. In industries like consumer electronics, where product cycles are short, this speed can be decisive.

Prototyping reveals issues that computer simulations may miss, such as thermal interactions between components or unexpected signal interference. Addressing these issues early results in a more robust, reliable final product.

Rigid FR4 prototype services enable designers to experiment with new ideas without committing to large-scale production. This flexibility fosters innovation, allowing for creative solutions to complex engineering challenges.

Many prototype services employ experienced engineers who can provide guidance on design optimization, material selection, and manufacturing processes. This expertise is invaluable for less experienced designers or those working on complex projects.

Selecting a prototype service provider requires careful consideration of several factors to ensure the best fit for a project:

Evaluate the provider’s ability to handle the design’s complexity, including layer count, minimum trace width/spacing, and via size. For multi-layer or high-density designs, ensure the service has the equipment and expertise to produce accurate prototypes.

Match the provider’s delivery options to the project timeline. While faster turnaround is often preferable, ensure that speed does not compromise quality—some services sacrifice inspection steps to meet tight deadlines.

Inquire about the provider’s quality control processes, including testing methods and certification (e.g., ISO 9001). Ask for sample boards to assess build quality, such as solder mask alignment and trace definition.

Look for providers that offer responsive customer service, including DFM feedback, design file review, and technical assistance. Clear communication is critical, especially when revisions are needed.

Compare pricing across providers, ensuring that quotes include all necessary services (e.g., testing, DFM checks) and that there are no hidden fees. Avoid selecting based solely on price, as low-cost providers may cut corners on quality.

If the project is expected to move to mass production, consider a prototype service that can also handle large-scale manufacturing. This continuity reduces the risk of design translation issues between prototyping and production.

As electronics design evolves, rigid FR4 PCB prototype services are adapting to new demands and technologies:

Many services now offer direct integration with popular design software (e.g., Altium, KiCad), allowing designers to upload files seamlessly and receive instant DFM feedback. This integration streamlines the design-to-prototype workflow, reducing errors and delays.

Providers are adopting eco-friendly processes, such as using recycled FR4 materials, water-based etchants, and energy-efficient manufacturing equipment. This aligns with the growing focus on sustainability in electronics and appeals to environmentally conscious clients.

Some prototype services now offer in-house testing, including thermal imaging, signal integrity analysis, and reliability testing, providing designers with comprehensive data to validate their designs. This one-stop-shop approach simplifies the development process.

Cloud-based platforms and digital ordering systems are making prototype services more accessible, allowing designers to upload files, select specifications, and track orders in real time. This digitization reduces administrative overhead and speeds up the ordering process.

These trends are making rigid FR4 PCB prototype services more efficient, flexible, and aligned with the needs of modern electronics development.

Despite their benefits, rigid FR4 PCB prototype services face challenges that designers should be aware of:

Rapid turnaround times can sometimes lead to compromises in quality, such as misaligned layers or incomplete testing. Designers must work with providers to find a balance that meets their timeline without sacrificing prototype reliability.

High-density interconnect (HDI) boards, with fine traces and microvias, require specialized equipment and expertise. Not all prototype services can reliably produce these designs, limiting options for designers working on advanced electronics.

Fluctuations in the supply of FR4 laminates or copper foil can occasionally delay prototype production. Choosing a provider with robust supply chain management helps mitigate this risk.

Multi-layer boards with custom features (e.g., blind vias, heavy copper) can be expensive to prototype, even in low volumes. Designers may need to prioritize features or phase prototyping to manage costs.

Rigid FR4 PCB Prototype Service is an indispensable resource for electronics designers, enabling the rapid, cost-effective validation of ideas before mass production. By leveraging the reliability and versatility of FR4, these services provide functional, accurate prototypes that accelerate innovation and reduce risk in product development. From concept validation to manufacturing feasibility, rigid FR4 prototypes play a critical role in ensuring that final products meet performance, reliability, and commercial goals. As technology advances, prototype services continue to evolve, offering faster turnaround, better integration with design tools, and more sustainable practices. For designers and businesses looking to bring electronic products to market efficiently, partnering with a reputable rigid FR4 PCB prototype service is a strategic investment in success.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB