-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Oct 17. 2025, 11:06:56

In today's fast-paced technological world, the demand for smaller, more efficient, and reliable electronic devices is at an all-time high. One of the key components driving this innovation is the Rigid Flex PCB assembly. But what exactly is it, and why is it gaining popularity?

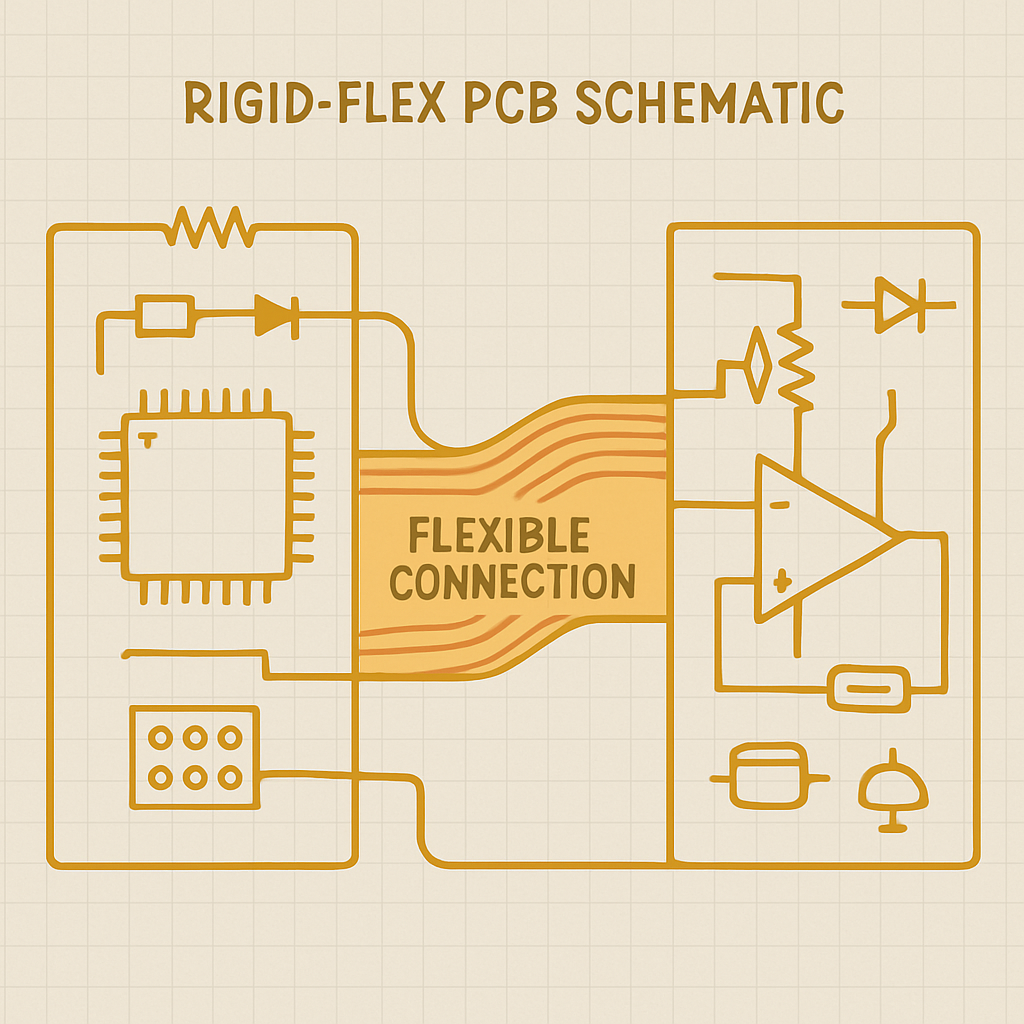

Rigid Flex PCBs combine the best features of rigid and flexible circuit boards into a single product. This hybrid technology offers numerous advantages over traditional PCB assemblies, making it an excellent choice for various applications.

Before diving into the advantages, let's break down what a Rigid Flex PCB assembly is. Essentially, it is a circuit board that incorporates both rigid and flexible substrates. The rigid sections provide support and stability, while the flexible parts allow the board to bend and conform to specific shapes. This unique design results in a highly adaptable and durable solution.

Rigid Flex PCBs have found their way into numerous industries, including aerospace, medical devices, consumer electronics, and automotive sectors, due to their versatile nature.

The creation of a Rigid Flex PCB assembly involves several stages, each critical to ensuring the final product's quality and functionality. Here's a brief overview of the process:

The first step in the PCB manufacturing process is the design phase. Engineers use specialized software to create detailed blueprints, which include the layout of all electrical components and connections. This design is then used to produce a prototype for testing and validation.

Rigid Flex PCBs require a combination of materials to balance flexibility and rigidity. Common materials include polyimide for flexible areas and FR-4 for rigid sections. The choice of materials can significantly impact the performance and durability of the PCB.

Once the materials are selected, the next step is layer stacking. This involves bonding multiple layers of conductive and insulating materials together. The layers are carefully aligned to ensure proper electrical connectivity and mechanical strength.

During the etching process, unwanted copper is removed from the surface of the board to create the desired circuit pattern. This is followed by lamination, where the layers are permanently bonded together using heat and pressure.

Holes are drilled into the board to allow for electrical connections between different layers. These holes are then plated with copper to ensure reliable conductivity.

Before shipping, Rigid Flex PCBs undergo rigorous testing to identify any defects or inconsistencies. Quality control measures are crucial to guarantee that the final product meets all design specifications and industry standards.

Now that we've covered the basics of what Rigid Flex PCBs are and how they are made, let's explore the numerous advantages they offer:

One of the most significant benefits of Rigid Flex PCB assembly is its design flexibility. The ability to combine rigid and flexible sections allows for more complex and compact designs. This is especially useful in applications where space is limited, such as wearable devices and medical implants.

Rigid Flex PCBs are known for their robust performance in harsh environments. The flexible sections can absorb mechanical stress, reducing the risk of damage from vibrations or impacts. Additionally, the use of high-quality materials ensures long-lasting durability.

By eliminating the need for connectors and cables between rigid and flexible boards, Rigid Flex PCBs help reduce the overall weight and space requirements of electronic devices. This makes them ideal for applications where minimizing weight and size is crucial, such as in aerospace and portable electronics.

The integrated design of Rigid Flex PCBs simplifies the assembly process. Fewer components and interconnections mean less time spent on assembly and fewer potential points of failure. This leads to cost savings and improved product reliability.

The continuous copper traces in Rigid Flex PCBs reduce signal loss and improve overall signal integrity. This is particularly important in high-frequency applications, where maintaining signal quality is critical.

From medical devices to consumer electronics, Rigid Flex PCB assemblies are versatile enough to meet the demands of various industries. Their adaptability makes them a popular choice for innovative and cutting-edge technologies.

In conclusion, Rigid Flex PCB assembly represents a significant advancement in the field of electronic circuit design. Its unique combination of flexibility and rigidity offers numerous advantages, including enhanced design flexibility, improved reliability, reduced space and weight, streamlined assembly processes, and enhanced signal integrity.

As technology continues to evolve, the demand for Rigid Flex PCBs is expected to grow. Their ability to meet the requirements of modern electronic devices makes them an essential component in the ongoing quest for innovation and efficiency.

Whether you're involved in designing consumer electronics, medical devices, or aerospace technology, considering Rigid Flex PCB assemblies could be the key to achieving greater performance and reliability in your products.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB