-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Oct 17. 2025, 11:05:04

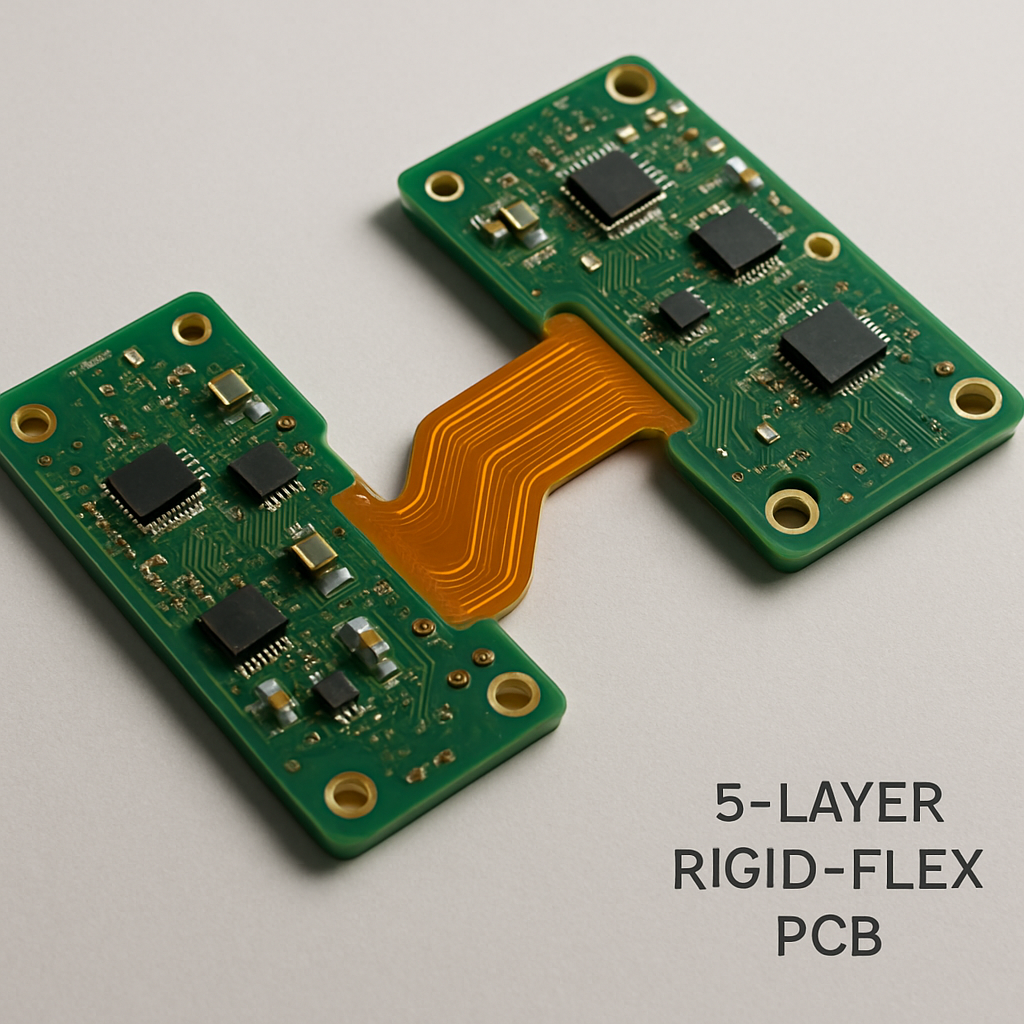

Printed Circuit Boards (PCBs) are the backbone of modern electronics. They connect all the components in a device, allowing it to function as intended. Among the various types of PCBs, rigid flex PCBs stand out for their unique combination of flexibility and rigidity, offering significant advantages in electronics design and manufacturing.

This article delves into the intricacies of the 5-layer rigid flex PCB assembly, explaining its benefits, the manufacturing process, and why it's a popular choice in today's technology-driven world.

Rigid flex PCBs are hybrid circuits that combine elements of both rigid and flexible PCBs. This combination allows for greater design versatility. They consist of multiple layers of flexible circuit substrates attached to rigid boards, providing a unified structure that can bend in specific areas while remaining stiff in others.

Space Efficiency: These PCBs are ideal for compact devices where space is at a premium. The flexible areas allow for folding and twisting without compromising circuit integrity.

Durability: The combination of rigid and flexible layers enhances durability, making them suitable for applications in demanding environments.

Weight Reduction: By eliminating the need for connectors and cables, rigid flex PCBs reduce the overall weight of the assembly.

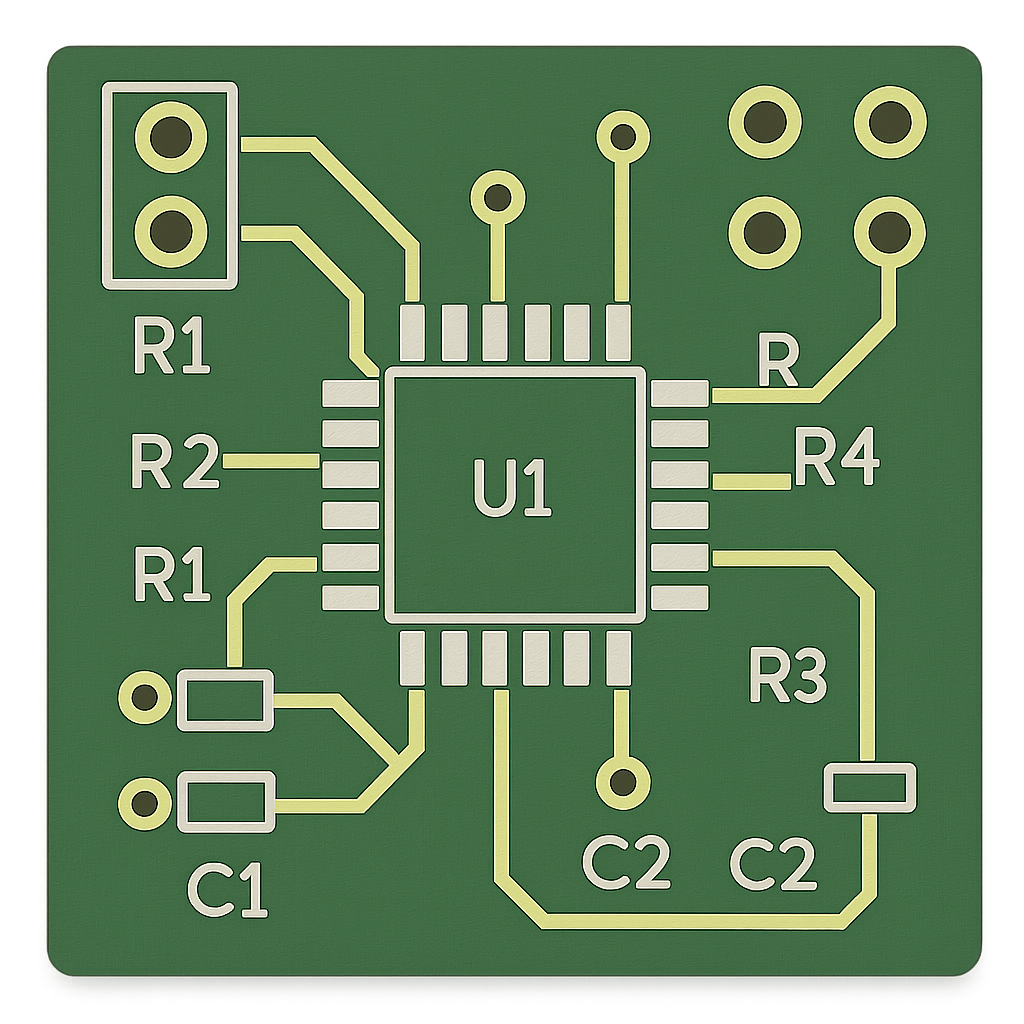

A 5-layer rigid flex PCB consists of five distinct layers, alternating between rigid and flexible materials. This configuration supports more complex circuit designs, allowing for increased functionality within a smaller footprint.

Top Rigid Layer: Serves as the primary circuit layer, providing structural support.

First Flexible Layer: Connects the top and bottom rigid layers, offering flexibility.

Middle Rigid Layer: Acts as a central backbone for added strength.

Second Flexible Layer: Connects the middle and bottom layers, maintaining flexibility.

Bottom Rigid Layer: Completes the structure, housing additional circuitry.

The manufacturing process for a 5-layer rigid flex PCB involves several crucial steps to ensure quality and functionality.

The design phase is crucial for ensuring that the PCB will function as intended. Engineers use specialized software to create a detailed blueprint of the circuit, considering factors like electrical performance, thermal management, and mechanical constraints.

Selecting the right materials is essential for achieving the desired flexibility and rigidity. Typically, polyimide is used for the flexible layers due to its excellent thermal stability and flexibility, while FR-4 is used for the rigid layers.

The layers are constructed individually, starting with the etching of copper circuits onto the flexible and rigid substrates. These layers are then laminated together using adhesive materials that can withstand high temperatures.

Holes are drilled into the board to create connections between the layers. These holes are then plated with a thin layer of copper to ensure electrical conductivity.

Once the PCB is constructed, components are soldered onto the board. The finished assembly undergoes rigorous testing to verify its electrical performance and durability.

Rigid flex PCBs are used in a wide range of applications due to their versatility and reliability. Some common uses include:

Consumer Electronics: Smartphones, tablets, and wearable devices benefit from the space-saving design of rigid flex PCBs.

Medical Devices: The durability and reliability of rigid flex PCBs make them ideal for medical equipment that requires precision and longevity.

Aerospace and Defense: In environments where reliability and performance are critical, rigid flex PCBs offer the necessary durability and weight savings.

While rigid flex PCBs offer numerous advantages, they also present unique challenges in manufacturing.

The intricate design of rigid flex PCBs requires meticulous planning and precision. Engineers must account for the mechanical movements of the flexible layers and ensure that the circuit remains intact during bending and folding.

The materials and processes involved in manufacturing rigid flex PCBs can be more expensive than traditional PCBs. However, the benefits often outweigh the costs, especially in high-performance applications.

5-layer rigid flex PCB assembly represents a significant advancement in PCB technology, offering a perfect blend of flexibility and rigidity. This makes them a favored choice for various industries seeking to optimize space, reduce weight, and improve durability.

Understanding the manufacturing process and the benefits of rigid flex PCBs can help businesses make informed decisions when designing and producing electronic devices. As technology continues to evolve, the demand for sophisticated and reliable PCBs like the 5-layer rigid flex will only grow.

By embracing these advancements, companies can stay ahead of the curve and meet the ever-increasing demands of modern electronics.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB