-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Oct 30. 2025, 09:06:10

In the world of electronics, where devices are becoming increasingly compact and efficient, Surface Mount Technology (SMT) has revolutionized the way electronic components are assembled. SMT assembly is a crucial process in the manufacturing of printed circuit boards (PCBs), which are the backbone of all electronic devices. This article aims to demystify SMT assembly, making it accessible and understandable for anyone interested in electronics.

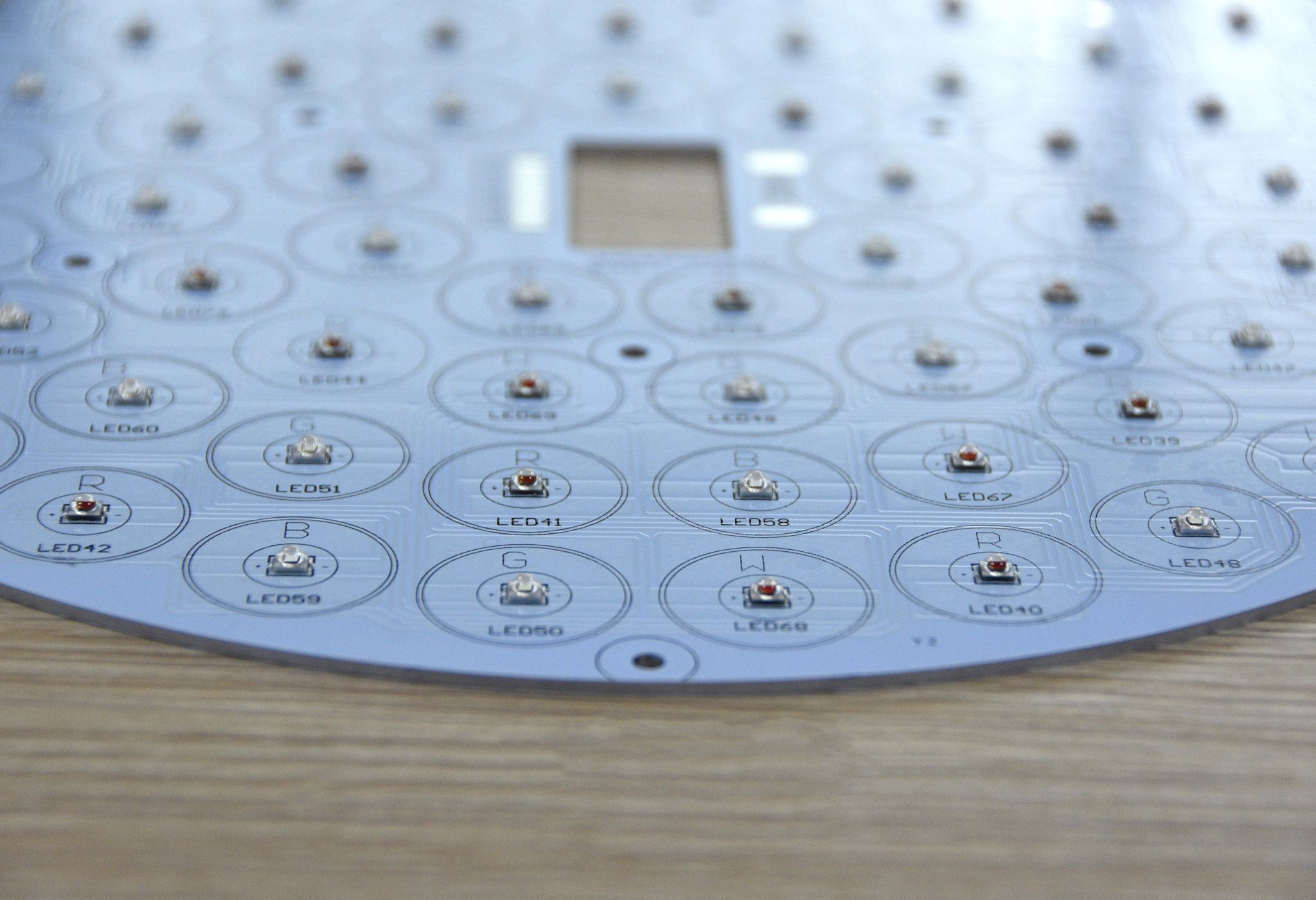

Surface Mount Technology, or SMT, is a method used to mount electronic components directly onto the surface of a printed circuit board (PCB). Unlike traditional through-hole technology, which involves inserting component leads into drilled holes on the PCB, SMT components are placed directly on the board's surface. This allows for a more compact and efficient design, which is especially important as electronics continue to shrink in size.

SMT assembly offers several advantages over traditional assembly methods:

Space Efficiency: SMT components are much smaller than their through-hole counterparts, allowing for more components to be placed on a single PCB. This results in smaller and lighter electronic devices.

Cost-Effective: With SMT, automated assembly processes can be used, reducing labor costs and increasing production speed.

Improved Performance: The shorter leads in SMT components reduce parasitic capacitance and inductance, which can improve the performance of high-frequency circuits.

Flexibility: SMT allows for more complex and dense PCB designs, which is essential for modern electronic devices.

The SMT assembly process involves several key steps, each critical to ensuring the quality and reliability of the final product. Here’s a step-by-step overview:

The process begins with the application of solder paste to the PCB. Solder paste is a mixture of powdered solder and flux, and it acts as an adhesive to hold the components in place during assembly. A stencil is used to apply the paste only on the pads where components will be placed.

Once the solder paste is applied, the PCB moves to a pick-and-place machine. This machine precisely places SMT components onto the solder paste-covered pads. The accuracy of this step is crucial, as even a slight misalignment can lead to defects.

After placement, the PCB is passed through a reflow oven. The oven heats the board to a temperature that melts the solder paste, creating a permanent bond between the components and the PCB. Proper temperature control is vital to avoid damage to components.

Quality control is a critical part of the SMT assembly process. After reflow soldering, the PCB is inspected for any defects, such as misaligned components or poor solder joints. Automated optical inspection (AOI) and X-ray inspection are commonly used to ensure the highest quality.

Finally, the assembled PCBs are tested to ensure they function correctly. This can involve functional testing, where the board is tested under normal operating conditions, or in-circuit testing, which checks the electrical connections on the PCB.

While SMT assembly has many advantages, it also presents some challenges:

Miniaturization: As components become smaller, handling and placing them accurately becomes more difficult.

Thermal Management: SMT components are more sensitive to heat, requiring careful thermal management during reflow soldering.

Defect Detection: With the increased complexity of PCBs, identifying defects can be more challenging and may require advanced inspection techniques.

As technology continues to advance, so does SMT assembly. Innovations in materials, processes, and equipment are continually being developed to meet the growing demands of the electronics industry. Future trends include:

3D Printing: The integration of 3D printing technology in PCB manufacturing can lead to more complex and customized designs.

Advanced Materials: The development of new materials can improve the performance and reliability of SMT assemblies.

Automation and AI: Increased automation and the use of artificial intelligence in the assembly process can enhance efficiency and reduce errors.

Surface Mount Technology has transformed the electronics manufacturing industry, enabling the production of smaller, faster, and more efficient devices. Understanding the basics of SMT assembly is crucial for anyone involved in electronics design and manufacturing. By leveraging the advantages of SMT and addressing its challenges, manufacturers can continue to innovate and meet the ever-growing demands of the modern world.

Whether you're a hobbyist, engineer, or manufacturer, grasping the fundamentals of SMT assembly will empower you to make informed decisions and enhance your electronic projects. As technology evolves, staying updated with the latest advancements in SMT will be key to success in the field of electronics.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB