-

- PCB TYPE

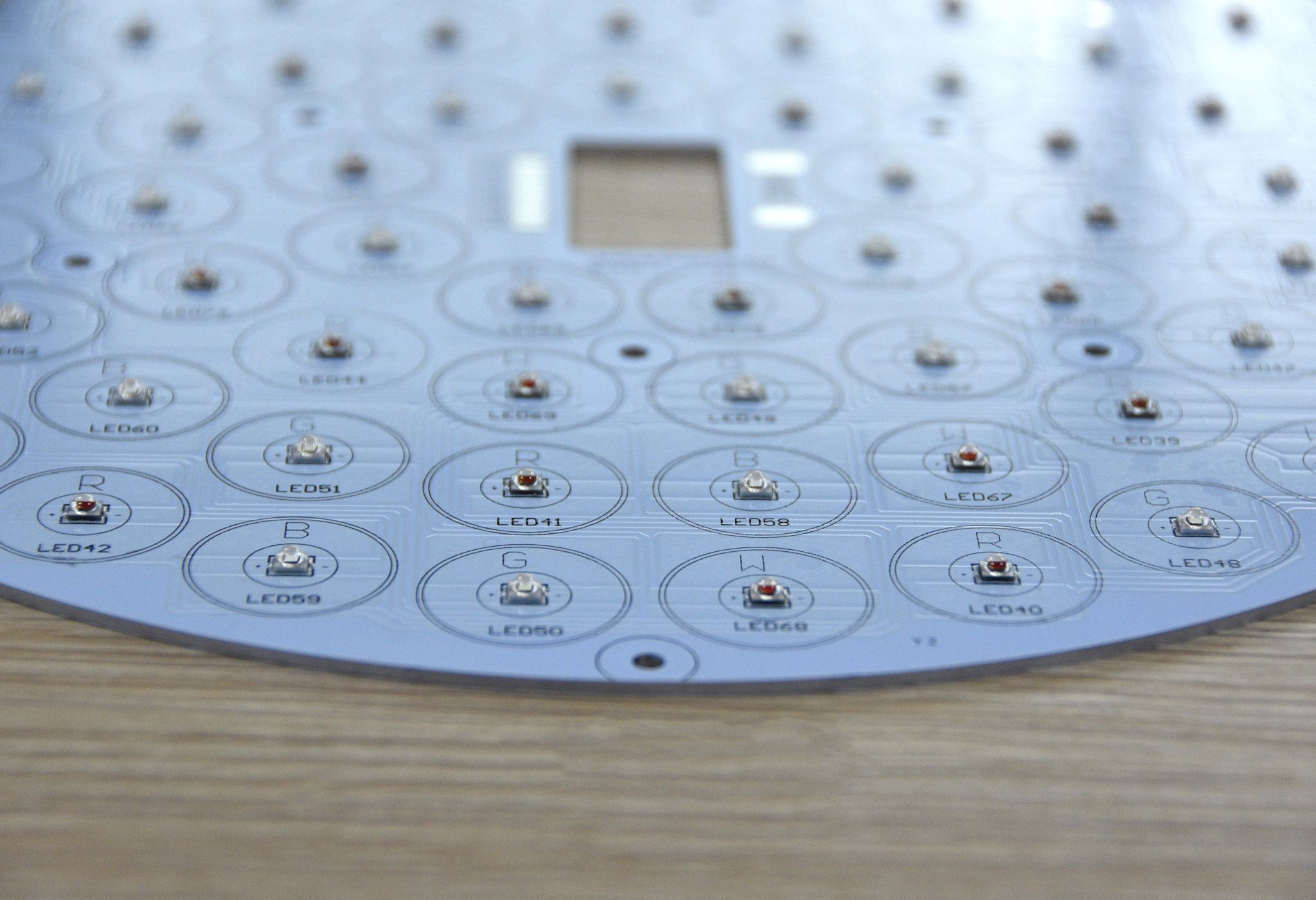

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Oct 30. 2025, 09:07:49

Printed Circuit Boards (PCBs) are at the heart of most electronic devices. From smartphones to microwaves, they play a crucial role in making sure these gadgets function properly. But how do these intricate boards come to life? Let's dive into the PCB assembly process to uncover the steps involved in transforming a simple design into a functional electronic component.

PCB assembly is the process of mounting electronic components onto a printed circuit board. This process involves several steps, from designing the board to testing the final product. Understanding this process is essential for anyone involved in electronics manufacturing or design.

Before diving into the assembly process, it's vital to grasp why PCB manufacturing is so critical. PCBs serve as the backbone of electronic devices, providing the necessary connections for electronic components to communicate and perform their functions. Without a reliable PCB, an electronic device cannot operate efficiently.

The first step in the PCB assembly process is designing the circuit board. This involves creating a schematic that outlines the board's electrical pathways. Engineers use specialized software to design the layout, ensuring that all components fit and function correctly. This step is crucial because any mistakes in the design can lead to malfunctions in the final product.

Once the design is complete, the next step is fabricating the PCB. This involves creating the physical board based on the design specifications. The fabrication process includes several stages, such as:

Etching: Removing unwanted copper from the board to create the desired pathways.

Lamination: Bonding multiple layers of the board together to form a complete PCB.

Drilling: Creating holes for component leads and vias.

Plating and Coating: Adding a protective layer to prevent corrosion and improve durability.

After the PCB is fabricated, solder paste is applied to the board's surface. Solder paste is a mixture of powdered solder and flux that helps attach components to the board. This step is usually done using a stencil to ensure precise application.

Once the solder paste is applied, the next step is placing the electronic components onto the board. This is typically done using automated machines known as pick-and-place machines. These machines accurately place components onto the board according to the design layout.

The next step in the PCB assembly process is soldering. During this step, the components are permanently attached to the board by melting the solder paste. There are several methods of soldering, including:

Reflow Soldering: The board passes through an oven where the solder paste is heated and melted.

Wave Soldering: The board is passed over a wave of molten solder that attaches components to the board.

Once the components are soldered onto the board, the next step is inspection and quality control. This step ensures that the assembly process was successful and that there are no defects. Inspection methods can include:

Visual Inspection: Checking the board for visible defects.

Automated Optical Inspection (AOI): Using machines to scan the board for defects.

X-ray Inspection: Inspecting the board's internal structure for hidden defects.

After inspection, the PCB undergoes testing to ensure it functions as intended. This involves checking the board's electrical performance and verifying that all components work correctly. Testing methods can include functional testing, in-circuit testing, and burn-in testing.

The last step in the PCB assembly process is the final assembly. This involves integrating the assembled PCB into the final product. It can include attaching additional components, connecting wires, and enclosing the board in a protective casing.

For businesses that require PCB assembly but lack the resources to do it in-house, PCB assembly services are available. These services offer expertise in all aspects of the assembly process, from design to testing. They provide businesses with high-quality PCBs without the need for significant investment in equipment or personnel.

Expertise: Access to skilled professionals with experience in PCB assembly.

Efficiency: Faster turnaround times due to specialized equipment and streamlined processes.

Cost Savings: Avoid the costs associated with purchasing equipment and hiring staff.

The PCB assembly process is a complex series of steps that transform a simple design into a functional electronic component. From designing and fabricating the board to placing components and testing the final product, each step is crucial for ensuring the reliability and functionality of electronic devices. Whether you're a small business or a large manufacturer, understanding this process can help you make informed decisions about your electronics production needs.

By leveraging PCB assembly services, businesses can ensure high-quality products while focusing on their core competencies. As technology continues to advance, the demand for efficient and reliable PCB assembly processes will only grow, making it an essential aspect of electronics manufacturing.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB