-

- PCB TYPE

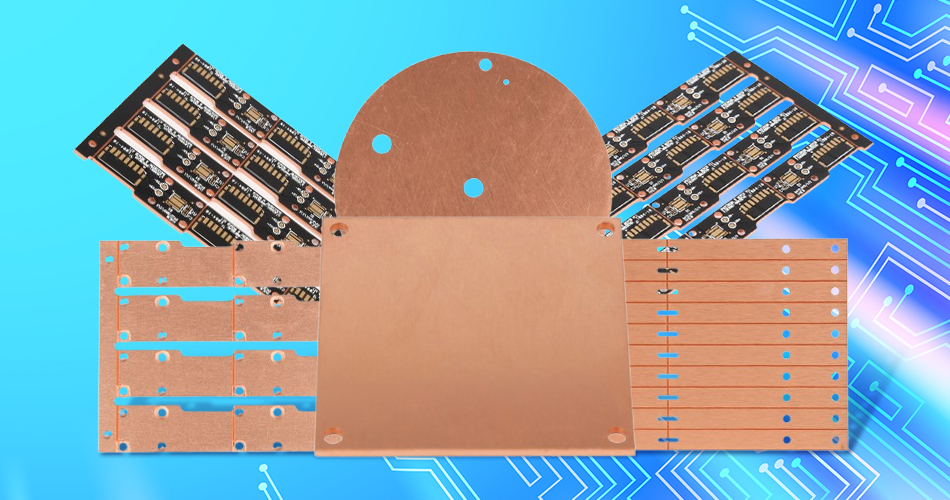

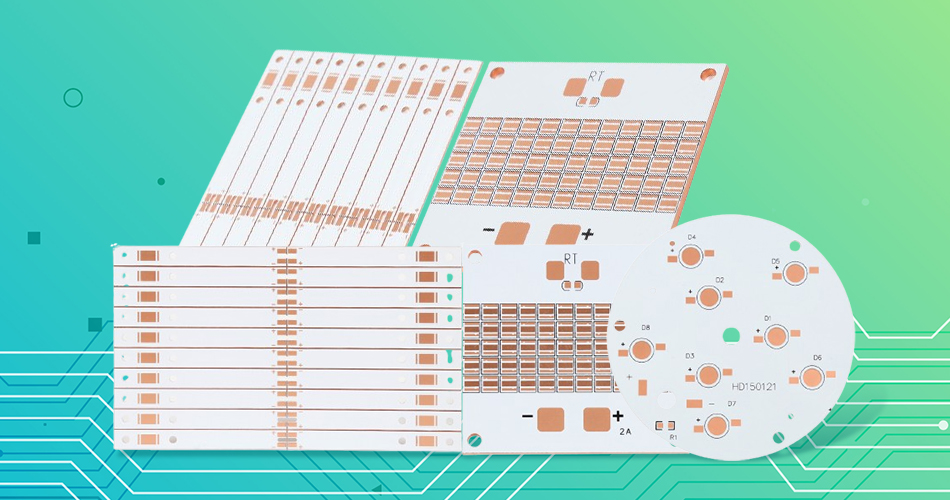

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Nov 19. 2025, 12:08:29

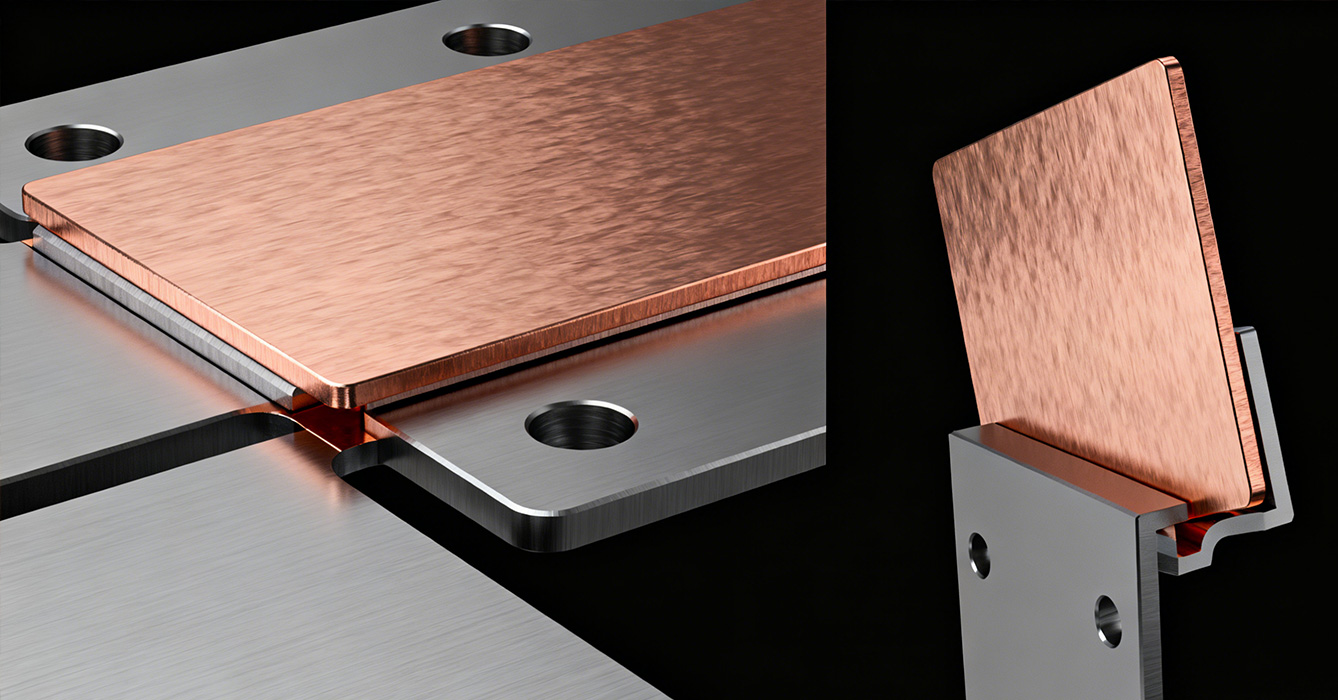

Sinkpad Copper Core stands as the core functional component of high-performance PCBs, directly determining the thermal dissipation efficiency and current-carrying capacity of power electronic systems. By integrating pure copper or advanced copper-based composites into optimized sinkpad structures, it addresses the fundamental challenge of concentrated heat and high-current transmission in compact devices—from EV powertrains to 5G base stations. Unlike conventional metal cores, modern sinkpad copper cores leverage material science breakthroughs (such as diamond/copper composites) and precision engineering to resolve long-standing dilemmas of thermal expansion mismatch and interface thermal resistance. This article delves into the material evolution, structural design principles, manufacturing breakthroughs, and cutting-edge applications of sinkpad copper cores, highlighting their pivotal role in advancing high-power electronics.

The performance leap of sinkpad copper cores stems from the strategic selection and innovation of copper-based materials, outperforming alternative substrates like aluminum in critical metrics.

Copper’s intrinsic properties define its irreplaceable role in sinkpad design:

Exceptional Thermal Conductivity: With a base thermal conductivity of 401 W/(m·K)—69% higher than aluminum (237 W/(m·K))—copper enables rapid heat transfer from component junctions to the sinkpad’s thermal management system . This minimizes hotspots that degrade semiconductors (e.g., IGBTs, MOSFETs) in high-power applications.

Low Electrical Resistance: Copper’s conductivity (5.96×10⁷ S/m) ensures minimal voltage drop even in high-current scenarios, reducing power loss by up to 40% compared to aluminum cores of the same cross-section.

Mechanical Robustness: Copper’s higher density (8.96 g/cm³ vs. aluminum’s 2.7 g/cm³) enhances structural rigidity, resisting warpage during thermal cycling (-40°C to 125°C) and vibration in automotive/industrial environments.

Traditional pure copper cores face limitations in extreme power density scenarios (e.g., 6G devices, quantum computing). Recent innovations in copper-based composites have addressed these gaps:

Diamond/Copper Composites: By integrating diamond particles (thermal conductivity up to 2300 W/(m·K)) into copper matrices, researchers have achieved composite cores with thermal conductivity of 763 W/mK—90% higher than pure copper—while reducing the coefficient of thermal expansion (CTE) to <10 ppm/K . This resolves the thermal mismatch between copper and semiconductor materials (e.g., silicon, GaN), eliminating interface cracking.

Interface Optimization: A key breakthrough lies in the diamond/copper interface design: a ultrathin (70nm) Ti coating forms a layered structure (diamond/TiC/CuTi₂/Cu) that achieves covalent bond-level interface strength (3.661 J/m²) while minimizing thermal resistance (interface conductance >800 MW/m²K) . This breaks the historical trade-off between interface bonding strength and heat transfer efficiency.

Cost-Effective Formulation: Using 45vol% diamond (vs. 50-70vol% in traditional processes) reduces material costs while maintaining high thermal performance, making the composite viable for mass production .

For weight-sensitive applications (e.g., aerospace, portable power devices), copper-aluminum hybrid cores offer a tailored solution:

The hybrid structure combines copper’s thermal/electrical conductivity in critical sinkpad regions with aluminum’s lightweight advantage (density 1/3 of copper) in non-critical areas, reducing overall PCB weight by up to 30% .

Manufacturing processes (e.g., friction stir welding) ensure metallurgical bonding between copper and aluminum, avoiding thermal resistance at the interface while mitigating galvanic corrosion risks.

Optimal sinkpad copper core design requires balancing thermal path efficiency, mechanical stability, and compatibility with PCB manufacturing processes.

Pedestal-Sinkpad Alignment: The copper core’s convex pedestal is precision-sized to match the thermal pad of high-power components (e.g., IGBT modules), ensuring intimate contact with minimal air gaps. Thermal interface materials (TIMs) with thermal conductivity >5 W/(m·K) (e.g., phase-change materials, liquid metal) fill micro-irregularities, reducing contact resistance by 30-50%.

Heat Spreading Geometry: The copper core features radial heat-spreading channels (width 0.3-0.5mm) extending from the pedestal, maximizing surface area for heat dissipation. This design reduces local temperature spikes by 20-25°C compared to solid copper cores of the same volume.

Gradient Thickness Distribution: The copper core employs variable thickness (1-4oz) across the PCB: thicker copper (3-4oz) in sinkpad regions for thermal/current handling, and thinner copper (1oz) in signal layers to reduce thermal expansion mismatch with dielectric substrates (e.g., FR-4, polyimide).

Stress-Relief Features: Curved edge profiles and dielectric buffer zones (width 0.2-0.3mm) around the copper core absorb thermal stress during temperature cycling, preventing delamination—a common failure mode in thick copper PCBs.

Via Integration: Blind/buried vias (diameter 0.1-0.2mm) are strategically placed around the copper core to connect signal layers without penetrating the thermal path. Resin-filled vias reinforce mechanical stability while maintaining the core’s flatness (tolerance ±0.05mm) for component mounting.

Thermoelectric Separation: The copper core is electrically isolated from signal traces via a high-temperature dielectric layer (breakdown voltage >10kV), ensuring no cross-talk between thermal and electrical pathways.

Advanced manufacturing processes enable the production of high-performance sinkpad copper cores while addressing traditional challenges (e.g., warpage, interface defects).

Low-Temperature High-Pressure (LTHP) Sintering: Used for diamond/copper composites, this process (600°C, 300MPa) replaces traditional high-temperature (900°C+) sintering, reducing thermal stress from CTE mismatch . Hard alloy molds (vs. graphite) ensure uniform pressure distribution, achieving >99% compactness.

Magnetron Sputtering for Interface Coating: The 70nm Ti coating on diamond particles is deposited via radio-frequency magnetron sputtering at 500°C, ensuring uniform coverage on all diamond facets ((001) and (111)) for consistent interface performance .

Symmetric Layer Stacking: The copper core is sandwiched between dielectric layers of equal thickness, balancing thermal expansion forces during lamination. Pre-lamination stress relief (annealing at 200°C for 2 hours) reduces residual stress in thick copper layers (≥3oz).

Post-Fabrication Flattening: Precision grinding (tolerance ±0.02mm) and laser leveling ensure the copper core’s surface flatness, critical for effective TIM contact and component soldering.

Thermal Performance Testing: Laser flash analysis (LFA) measures thermal conductivity with ±5% accuracy, while infrared thermography maps temperature distribution under 100A current load.

Interface Integrity Inspection: X-ray computed tomography (CT) detects voids (>5μm) in the copper-dielectric interface, and pull tests (≥50N/mm²) verify bonding strength.

Reliability Cycling: Thermal cycling (-40°C to 125°C, 1000 cycles) and vibration testing (10-2000Hz, 10g acceleration) validate performance in harsh environments.

Sinkpad copper cores are tailored to high-power, high-temperature scenarios where thermal management directly impacts reliability and performance.

Powertrain Systems: In traction inverters and battery management systems (BMS), diamond/copper composite cores dissipate heat from IGBTs (200-400A current) and reduce junction temperatures by 30-40°C, extending component lifespan by 2-3x.

Fast-Charging Modules: Thick copper cores (4oz) handle 350A+ currents in DC fast chargers, minimizing voltage drop (<2%) and enabling 15-minute full charging.

RF Power Amplifiers: Copper-aluminum hybrid cores balance thermal performance (cooling 50W RF modules) and weight reduction, critical for tower-mounted base stations.

AI Servers & Data Centers: Diamond/copper cores cool dense GPU/CPU arrays (thermal density >500 W/cm²) in AI servers, preventing thermal throttling and maintaining compute efficiency.

Motor Drives & Inverters: Sinkpad copper cores (2-3oz) manage heat in industrial inverters (100-500kW), ensuring 24/7 operation in temperatures up to 85°C.

Renewable Energy Systems: In solar inverters and wind turbine converters, copper cores withstand humidity and temperature cycling, reducing maintenance downtime by 40%.

The evolution of sinkpad copper cores is driven by the growing demand for higher power density, lightweight design, and sustainability.

Graphene-Enhanced Copper Cores: Graphene additives (0.5-1wt%) boost thermal conductivity by 20-30% compared to pure copper, while reducing weight by 10%. Pilot production has achieved 500 W/(m·K) thermal conductivity for commercial applications.

Multi-Filler Composites: Combining diamond and graphene in copper matrices targets thermal conductivity >1000 W/(m·K), addressing the needs of quantum computing and 6G communication devices.

Generative Design Tools: AI algorithms simulate thermal flow, current distribution, and stress in copper cores, optimizing geometry (e.g., pedestal size, heat channels) to reduce material usage by 15-20% while maintaining performance.

Digital Twin Technology: Virtual replicas of copper core manufacturing processes (sintering, lamination) predict defects, reducing production scrap rates from 8-10% to <3%.

Recycled Copper Integration: High-purity recycled copper (99.85%) is used in core production, reducing carbon emissions by 65% compared to virgin copper.

Eco-Friendly Etching & Plating: Lead-free ENEPIG coatings and water-based etching solutions eliminate hazardous waste, aligning with EU RoHS and Chinese GB/T 26125 standards.

End-of-Life Recycling: Thermoelectric separation design enables efficient recovery of copper cores (95% recycling rate) from discarded PCBs, supporting circular economy principles.

Sinkpad Copper Core has evolved from a simple thermal conductor to a highly engineered component that integrates advanced materials, precision design, and innovative manufacturing. By leveraging copper’s inherent advantages and breakthroughs in composite technology (e.g., diamond/copper), it resolves the critical trade-offs between thermal performance, current-carrying capacity, and mechanical stability in high-power electronics. From EV powertrains to AI servers, sinkpad copper cores enable the miniaturization and efficiency gains required for next-generation technologies. As materials science advances (e.g., graphene composites) and manufacturing becomes more sustainable, sinkpad copper cores will remain at the forefront of thermal management innovation, powering the transition to higher performance, more reliable, and eco-friendly electronic systems.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB