-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Nov 24. 2025, 11:34:09

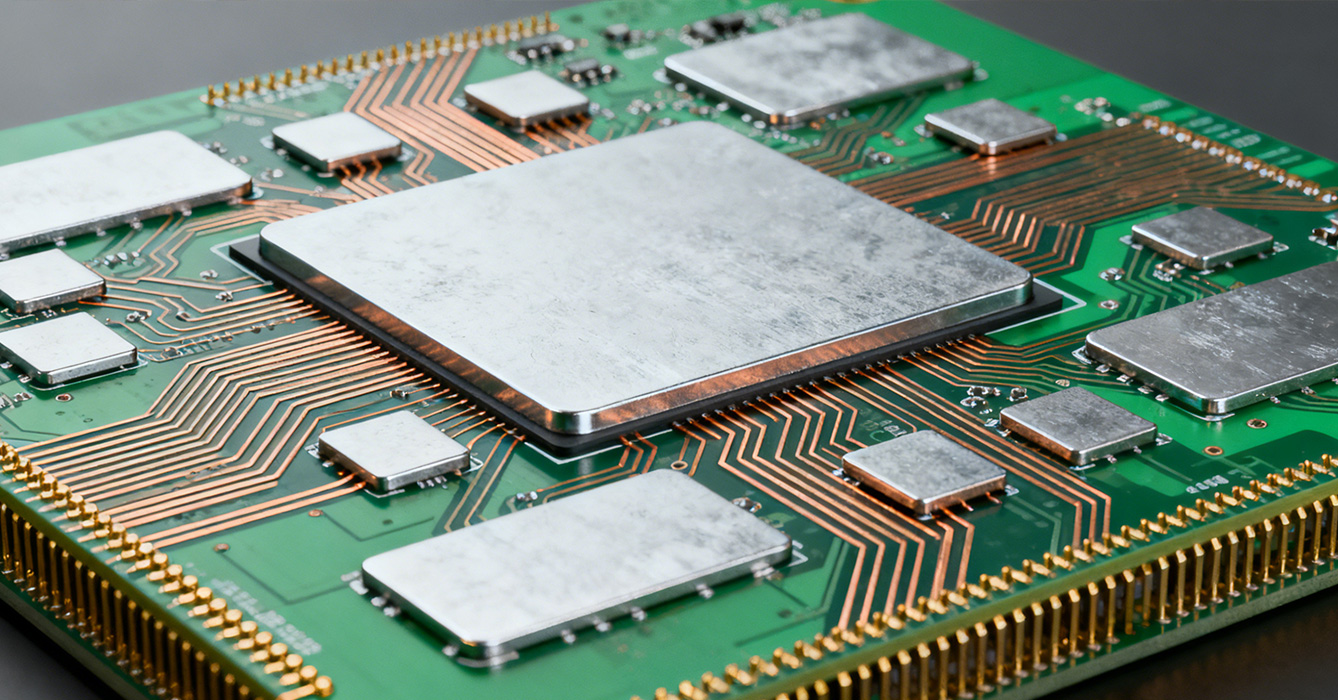

Sinkpad PCB is a specialized thermal management solution designed for high-power electronic systems, integrating built-in thermal sink structures directly into the PCB substrate. Unlike standard PCBs that rely on external heat dissipation components, sinkpad PCB embeds a dedicated metal-based sink (typically aluminum, copper, or ceramic-metal hybrid) within the board layout—working in tandem with thermal pads to resolve concentrated heat buildup. Its core advantage lies in integrated thermal-mechanical design: eliminating the need for separate heat sinks, reducing overall device size, and ensuring efficient heat transfer from components (LEDs, semiconductors, power modules) to the external environment. Suitable for power ranges from 10W to 500W, sinkpad PCB dominates scenarios where compactness and reliability are critical, from LED lighting to new energy vehicles. This article simplifies the core logic, synergistic design, key applications, and future trends of sinkpad PCB, focusing on practical value for engineers and manufacturers.

Sinkpad PCB’s thermal performance stems from the seamless collaboration of three key components, addressing heat transfer at every stage:

The sinkpad is a localized thick metal structure (integrated into the PCB’s core layer) designed to directly contact high-heat components. Unlike external heat sinks, it becomes part of the PCB itself—shortening the heat transfer path and avoiding assembly gaps. Key roles:

Absorbs concentrated heat from components (e.g., LED chips, IGBTs) at the source

Spreads heat uniformly across the PCB substrate, eliminating hotspots

Provides structural support for heavy components, enhancing mechanical stability

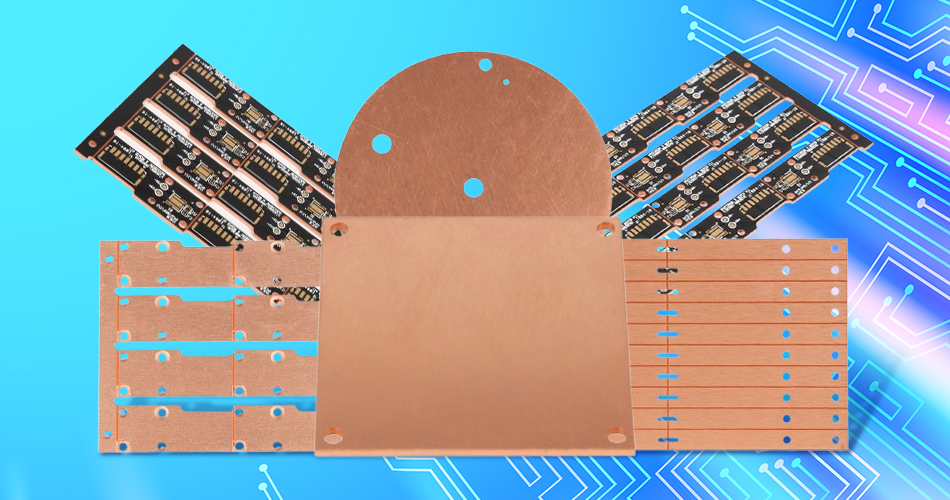

Sinkpad PCB typically uses metal core substrates (aluminum, copper, ceramic-metal hybrid) to amplify the sinkpad’s heat dissipation capability:

Aluminum core: Cost-effective and lightweight, paired with sinkpads for mainstream applications (mass-produced LED lighting, consumer electronics)

Copper core: High thermal conductivity, matched with sinkpads for ultra-high-power scenarios (industrial inverters, EV powertrains)

Ceramic-metal hybrid core: Resists extreme temperatures, combined with sinkpads for harsh-environment use (aerospace, medical equipment)

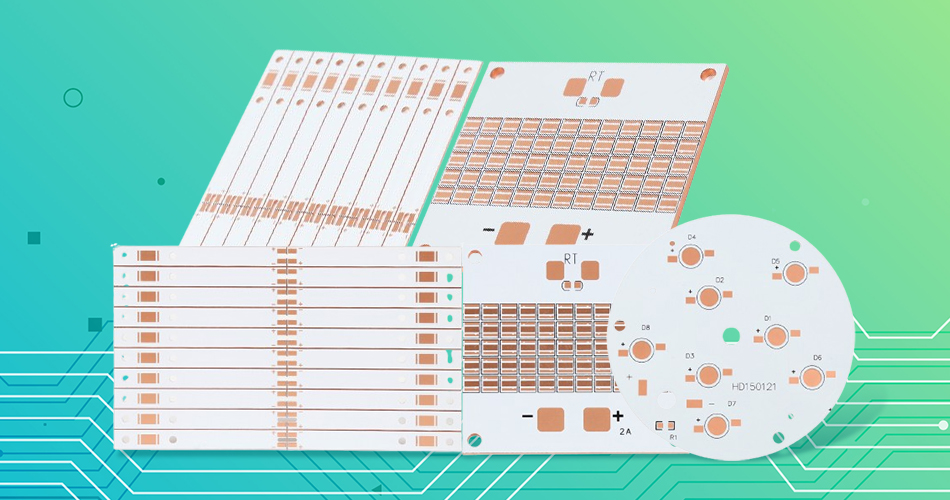

To maximize heat transfer between components and the sinkpad, thermal pads are used to fill micro-gaps:

Deformable thermal pads (graphite-polymer, phase-change, metal-particle) ensure full contact with both the component and sinkpad

Reduces interface thermal resistance significantly, complementing the sinkpad’s internal heat spreading

Adapts to thermal expansion differences, preventing delamination during temperature cycles

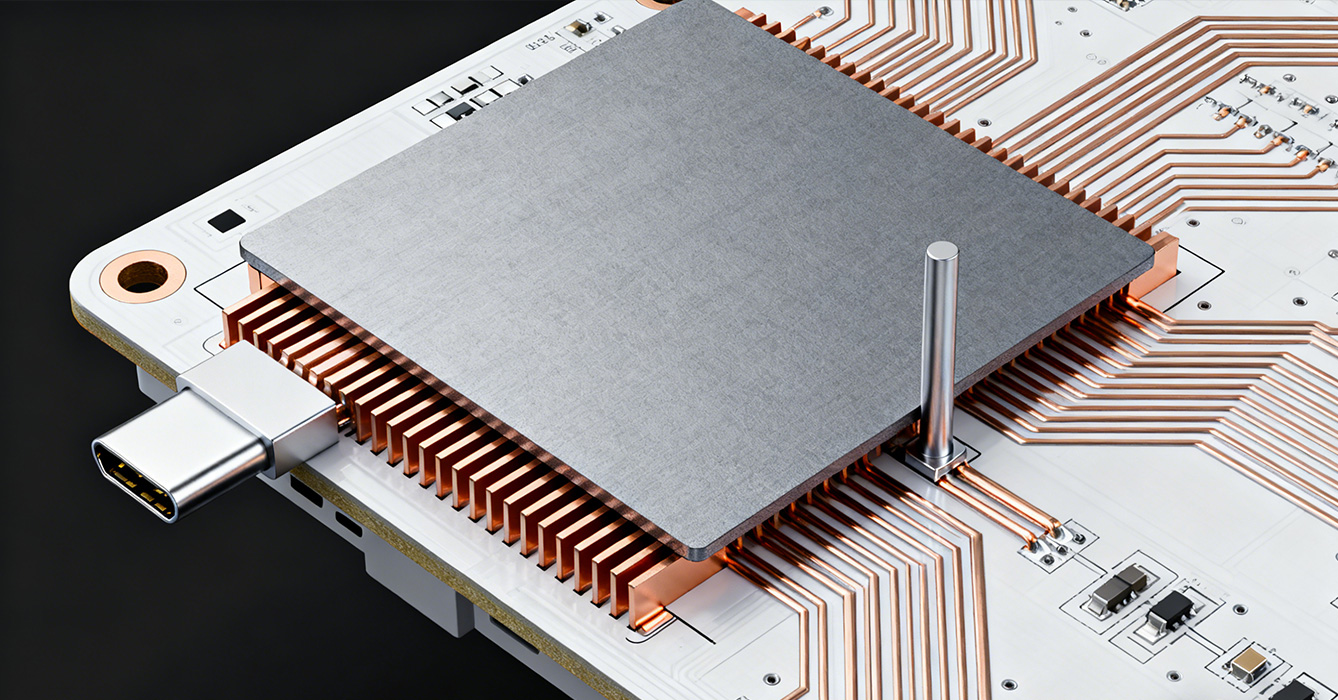

By integrating the sink structure into the PCB, sinkpad PCB eliminates the need for external heat sinks—reducing device volume by 30% or more compared to traditional "PCB + heat sink" combinations. Ideal for slim products like LED panel lights, compact chargers, and automotive on-board electronics.

The direct component-sinkpad contact, combined with metal core substrate heat spreading, creates a continuous thermal path—ensuring faster heat dissipation than discrete solutions. Critical for high-power density components where overheating leads to performance degradation or shortened lifespan.

Integrated design reduces part counts (no separate heat sinks, screws, or adhesives) and simplifies assembly processes. For mass production, this translates to lower manufacturing costs and higher yield rates, especially in sectors like LED lighting and consumer electronics.

The sinkpad’s integration into the PCB core enhances mechanical rigidity, resisting warpage during thermal cycling or vibration. This reliability makes it suitable for rugged environments like industrial machinery, automotive under-hood systems, and outdoor equipment.

Residential/commercial lighting: Slim LED downlights, panel lights, and track lights use aluminum core sinkpad PCB—combining compact design with efficient heat dissipation for long-term lumen maintenance.

Industrial/outdoor lighting: High-power LED high-bays, floodlights, and street lights adopt copper core or hybrid core sinkpad PCB, withstanding extended operation hours and harsh weather.

Traction inverters: Copper core sinkpad PCB cools high-power semiconductors (SiC/GaN modules), ensuring stable operation under extreme loads.

Battery Management Systems (BMS): Aluminum core sinkpad PCB monitors battery cells, withstanding temperature fluctuations and vibration.

On-Board Chargers (OBCs): Hybrid core sinkpad PCB supports fast charging, balancing thermal stability and compact design.

Power inverters & motor drives: Sinkpad PCB reduces device footprint while cooling high-current components, enabling integration into compact industrial machinery.

IoT & edge devices: Low-power sinkpad PCB for industrial sensors and controllers, operating reliably in dust, humidity, and temperature-variable environments.

Fast chargers (65W+): Compact sinkpad PCB dissipates heat from high-power charging chips, enabling slim charger designs without overheating.

Gaming devices & power banks: Lightweight sinkpad PCB balances thermal efficiency and portability, extending device lifespan.

Graphene/CNT-enhanced sinkpads: Boost thermal conductivity while reducing weight, enabling higher power density designs.

Sustainable materials: Recycled metal cores and bio-based substrates align with global environmental goals, without compromising performance.

Embedded temperature sensors: Real-time thermal monitoring for predictive maintenance in critical applications (e.g., EV powertrains, industrial inverters).

Adaptive thermal structures: Shape-memory or phase-change integrated sinkpads that adjust to temperature changes, optimizing heat dissipation dynamically.

Ultra-thin sinkpad designs: Supporting even slimmer devices (e.g., wearable electronics, miniaturized industrial sensors).

High-power hybrid sinkpads: Ceramic-copper hybrid sinkpads for 500W+ applications, bridging extreme thermal performance and structural stability.

Sinkpad PCB redefines thermal management for high-power electronics through its integrated design—combining built-in sink structures, metal core substrates, and thermal pad synergy to deliver compactness, efficiency, and reliability. From mass-produced LED lighting to high-performance EV components, it addresses the core need of "heat dissipation without compromising size or cost" across industries. As material innovations and intelligent design advance, sinkpad PCB will continue to be a cornerstone of high-power electronic development—enabling smaller, more efficient, and more sustainable devices. For engineers and manufacturers, leveraging sinkpad PCB’s integrated advantage is key to unlocking product competitiveness in a power-dense, compact-focused market.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB