-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Nov 24. 2025, 11:31:56

Thermal Pad MCPCB (Metal Core PCB) has established itself as a versatile thermal management platform for high-power electronic systems, integrating high-conductivity thermal pads with specialized metal cores (aluminum, copper, ceramic-metal hybrid) to resolve heat dissipation bottlenecks across power ranges (10W-500W). Unlike single-substrate solutions, Thermal Pad MCPCB adapts to diverse performance demands—from cost-sensitive mass production to extreme-power scenarios and harsh-environment applications. As electronic devices pursue higher power density, smaller footprints, and broader environmental adaptability, its core advantage lies in customizable thermal-mechanical-electrical synergy, enabling dominance across sectors from consumer electronics to aerospace. This article explores the universal technical framework, metal core-thermal pad matching strategies, cross-power design optimizations, and high-value applications, providing a streamlined guide for multi-scenario thermal management.

The performance of Thermal Pad MCPCB originates from the complementary interaction between thermal pads and MCPCB’s metal core, addressing two fundamental thermal challenges in high-power electronics:

All MCPCBs suffer from inherent interface gaps between power components and the metal core, caused by surface micro-irregularities and assembly tolerances. Thermal pads—engineered with deformable, high-conductivity materials—fill these gaps to form a continuous heat transfer path, reducing interface thermal resistance by 50-70% compared to direct mounting. Key combinations deliver targeted results:

Cost-effective aluminum core paired with graphite pads achieves low interface resistance, suitable for mainstream applications

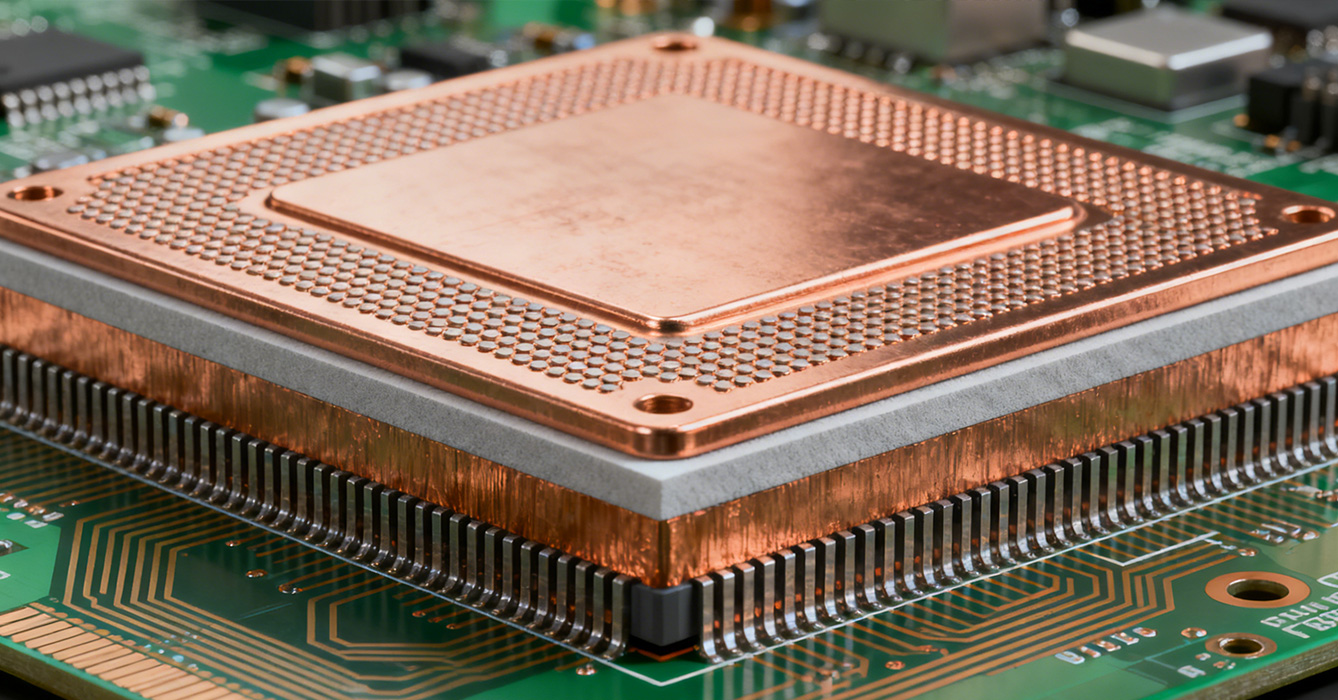

High-performance copper core with metal-particle pads minimizes thermal resistance, critical for ultra-high-power systems

Ceramic-metal hybrid core with phase-change pads maintains stable thermal resistance across extreme temperature ranges

MCPCB’s metal core acts as a primary heat spreader, while thermal pads enhance this capability by pre-dispersing concentrated heat before it reaches the core. For high-power density components, the thermal pad distributes point-source heat into a uniform thermal field, preventing metal core hotspots that cause local overheating. This synergy is particularly critical for arrayed components (ensuring consistent temperature across devices) and compact MCPCBs (maximizing heat spreading in limited space).

Thermal pads are tailored to match the thermal expansion coefficient (CTE) of MCPCB metal cores, mitigating thermal stress during temperature cycling:

Aluminum core (moderate CTE) pairs with graphite/polymer pads to reduce interface shear stress significantly

Copper core (lower CTE) combines with copper-particle pads to prevent delamination through repeated thermal cycles

Ceramic-metal hybrid core (low CTE) uses ceramic-filled pads to ensure structural integrity in aerospace-grade temperature ranges

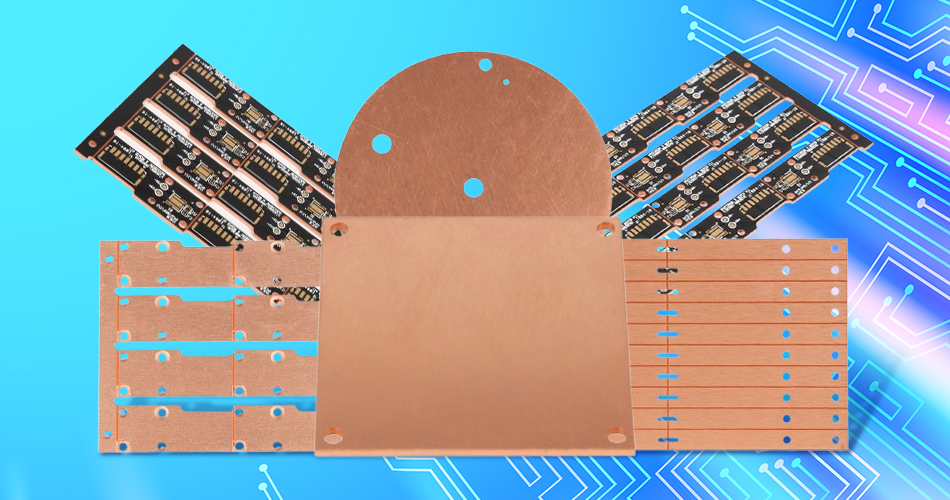

Thermal Pad MCPCB’s versatility stems from precise matching of metal core type and thermal pad material, optimized for specific power levels and application environments:

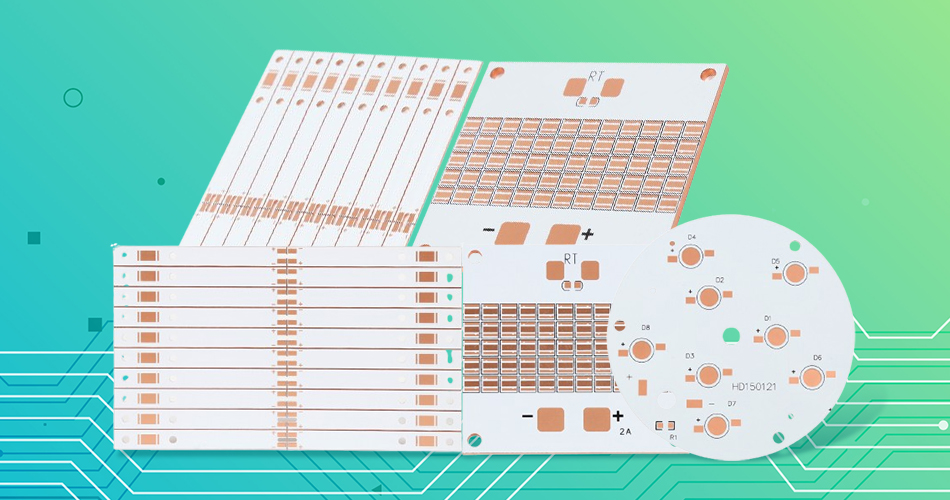

A mainstream choice for mass production, aluminum core offers balanced thermal conductivity and lightweight properties at a competitive cost. It pairs with graphite-enhanced polymer pads or phase-change materials—both delivering reliable thermal transfer for mid-range power demands. Ideal for 10W-200W applications, this combination excels in mass-produced LED lighting (residential/commercial), fast chargers, and automotive interior electronics.

Designed for extreme power requirements, copper core provides superior thermal conductivity at the cost of higher density and investment. It matches with metal-particle composite pads or liquid metal-infused pads, which maximize heat transfer efficiency. Suited for 200W-500W scenarios, this pairing is critical for industrial power inverters, EV on-board chargers, and high-power laser modules.

Engineered for harsh conditions, ceramic-metal hybrid core balances thermal conductivity and thermal stability with a low CTE. It pairs with ceramic-filled phase-change pads or diamond-particle composites, offering resistance to extreme temperatures and environmental stress. Suitable for 50W-300W applications, it excels in aerospace avionics, high-temperature industrial sensors, and medical imaging equipment.

Thermal Conductivity Balance: Thermal pad conductivity should be proportional to the metal core’s performance to avoid creating new bottlenecks

Cost-Performance Tradeoff: For 80% of mid-power applications, aluminum core + graphite pad achieves optimal balance at a fraction of the cost of high-end alternatives

Environmental Adaptability: Outdoor/extreme-temperature applications prioritize phase-change or ceramic-filled pads for durability, while indoor high-power systems use metal-particle pads for maximum conductivity

Thermal Pad Optimization: Ultra-thin graphite-polymer pads to fit slim designs (e.g., compact LED downlights)

Metal Core Design: Thin aluminum core with minimal copper pour to reduce weight and cost

Key Application: Portable electronics, residential LED bulbs, IoT sensors

Thermal Pad Optimization: Thin-to-moderate thickness phase-change or metal-particle pads, pre-cut to component footprints

Metal Core Design: Medium-thickness aluminum core with radial copper pour to enhance heat spreading; optional integrated micro-fins for passive cooling

Key Application: Commercial LED lighting, industrial motor drives, EV auxiliary chargers

Thermal Pad Optimization: Moderate-to-thick liquid metal or diamond-particle pads, paired with precision-ground metal cores for maximum contact

Metal Core Design: Thick copper or ceramic-metal hybrid core; integrated macro-fins or liquid cooling channels

Key Application: Industrial power inverters, EV traction inverters, high-power laser cutting equipment

Thermal Pad Sizing: Pad size slightly exceeds component thermal pad to ensure full contact without excess thermal mass

Interface Pressure: Assembly with moderate pressure to compress thermal pads to optimal thickness for maximum contact

Dielectric Layer Compatibility: Thermal pad material selected to match MCPCB’s dielectric layer, avoiding compatibility issues

Traction Inverters: Copper core + liquid metal thermal pads cool high-power semiconductors, reducing junction temperature and extending battery range

Battery Management Systems (BMS): Aluminum core + phase-change pads monitor battery cells, withstanding under-hood temperature fluctuations

On-Board Chargers (OBCs): Ceramic-metal core + high-performance pads support fast charging, ensuring thermal stability during extended cycles

High-Power Inverters & Converters: Copper core + metal-particle pads manage heat from high-power components, enabling 24/7 operation with minimal downtime

Motor Drives: Aluminum core + graphite pads reduce drive unit footprint, ideal for compact robotics

Avionics Systems: Ceramic-metal core + ceramic-filled thermal pads cool power-dense components, withstanding extreme temperatures and radiation

UAV Power Modules: Lightweight aluminum core + graphite pads balance thermal efficiency and weight, critical for flight endurance

Medical Imaging Equipment: Ceramic-metal core + phase-change pads cool high-power components, ensuring temperature stability for imaging precision

Laser Therapy Devices: Copper core + liquid metal pads dissipate heat from high-power laser diodes, maintaining beam consistency over long lifespans

MXene-Infused Thermal Pads: Significantly higher conductivity with CTE matching metal cores, enabling ultra-high-power designs

Graphene-Coated Metal Cores: Enhanced thermal conductivity without cost escalation

Self-Healing Thermal Pads: Microcapsule-based designs repair interface gaps from thermal cycling, doubling lifespan

Embedded Sensor Integration: Thermal pads with built-in temperature sensors enable real-time monitoring, supporting predictive maintenance in critical applications

Adaptive Thermal Pads: Shape-memory polymer designs adjust thickness dynamically based on temperature, maintaining optimal contact

Recycled Metal Cores: High-purity recycled copper/aluminum cores paired with bio-based thermal pad polymers reduce carbon footprint

Low-Energy Production: Waterless etching and solvent-free lamination align with global sustainability goals

Thermal Pad MCPCB represents a scalable, customizable thermal management platform that adapts to the full spectrum of high-power electronic needs—from cost-sensitive mass production to extreme-performance, harsh-environment applications. By matching thermal pad materials to metal core properties (aluminum for cost, copper for power, ceramic-metal for durability) and optimizing design for specific power ranges, it resolves the core pain point of "heat dissipation vs. form factor/cost" across industries. As material innovations and intelligent features advance, Thermal Pad MCPCB will continue to push the boundaries of high-power electronics—enabling smaller, more efficient, and more reliable devices in EVs, industrial automation, aerospace, and beyond. For engineers and manufacturers, mastering the metal core-thermal pad matching strategy is key to unlocking the full potential of MCPCB technology.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB