-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Nov 11. 2025, 13:35:04

Sinkpad PCB represents a specialized thermal management solution designed to address the heat dissipation challenges of high-power electronic components. Unlike conventional PCBs that rely on external heatsinks or discrete thermal vias alone, a sinkpad PCB integrates a dedicated, thermally conductive pad (sinkpad) directly into the board structure—creating a low-resistance pathway for heat to flow from components to cooling systems. This integrated design is particularly critical for applications where space is constrained and heat density is high, such as power modules, LED drivers, and automotive electronics. By merging the structural function of a PCB with the thermal performance of a heatsink, sinkpad PCBs eliminate the inefficiencies of separate thermal interfaces, ensuring consistent heat removal and extending component lifespan. This article explores the core design features, performance advantages, industry-specific applications, and evolving innovations of sinkpad PCBs.

The effectiveness of sinkpad PCBs stems from three key design elements that optimize thermal transfer while maintaining electrical integrity:

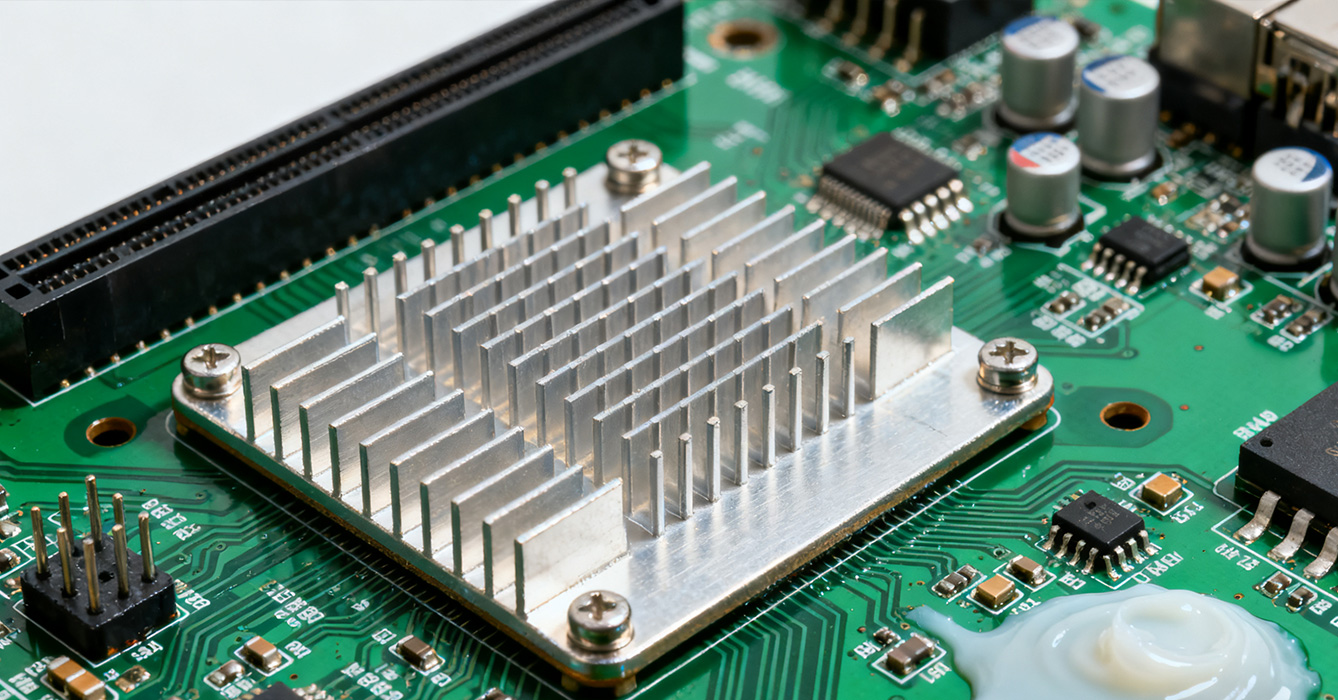

- Embedded Sinkpad Structure: The sinkpad itself is a thick, high-thermal-conductivity metal layer (typically copper or aluminum) embedded within the PCB stackup. It is directly bonded to the component pad layer, eliminating air gaps and reducing thermal resistance. For example, a sinkpad for a power MOSFET might be a 2mm-thick copper pad integrated between the top signal layer and inner ground plane, creating a direct heat path from the MOSFET to the sinkpad.

- Thermal Interface Optimization: Unlike external heatsinks that require thermal paste or pads, the sinkpad’s direct integration with the PCB ensures a permanent, low-resistance thermal bond. Some designs use solderable sinkpads, where components are soldered directly to the sinkpad—further enhancing heat transfer by leveraging solder’s higher thermal conductivity compared to traditional TIMs.

- Electrical Isolation Integration: To prevent short circuits between the conductive sinkpad and other PCB layers, a thin layer of high-temperature insulating material (e.g., ceramic-filled prepreg) is placed between the sinkpad and adjacent signal/ground layers. This insulation maintains electrical separation while allowing heat to pass through efficiently.

Sinkpad PCBs offer distinct benefits that make them superior to conventional heat management approaches:

By eliminating the thermal resistance of external heatsink attachments (e.g., screws, clips, or TIMs), sinkpad PCBs achieve thermal resistance values 25–35% lower than traditional PCB + heatsink combinations. This is critical for high-power components like IGBTs, where even small resistance reductions prevent thermal throttling.

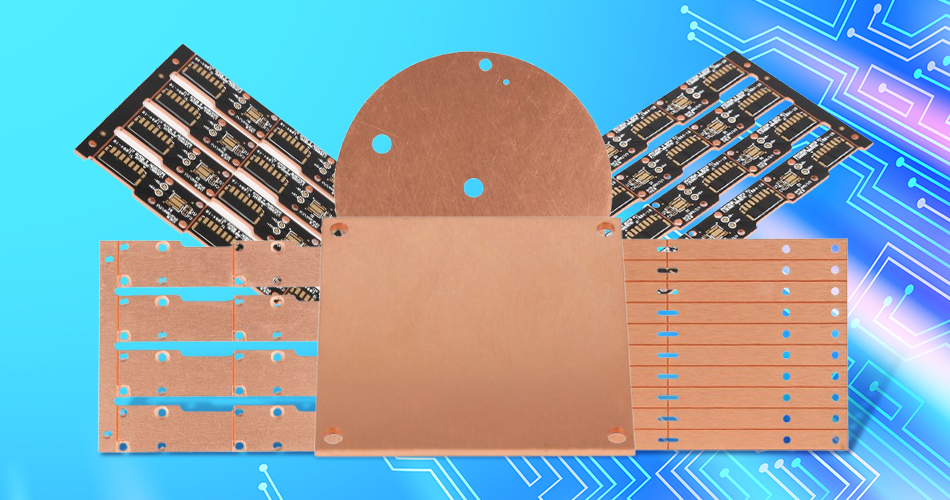

The integrated sinkpad removes the need for bulky external heatsinks, reducing the overall footprint of the electronic assembly by up to 40%. This makes sinkpad PCBs ideal for compact devices like portable power tools or automotive infotainment systems where space is at a premium.

The permanent bond between the sinkpad and PCB eliminates mechanical stress from heatsink mounting, which can degrade solder joints over time. Additionally, the embedded design protects the thermal path from environmental factors like dust and vibration, ensuring consistent performance in harsh operating conditions.

Industrial motor drives and power inverters use sinkpad PCBs to cool high-current components like thyristors and power diodes. The sinkpad’s low thermal resistance ensures these components operate within safe temperature ranges even during continuous high-load operation, reducing downtime from thermal failures.

Electric vehicle (EV) onboard chargers and DC-DC converters rely on sinkpad PCBs to manage heat in tight underhood spaces. Sinkpads integrated with the PCB’s power module layer direct heat to the vehicle’s liquid cooling system, maintaining performance during fast charging and high-speed driving.

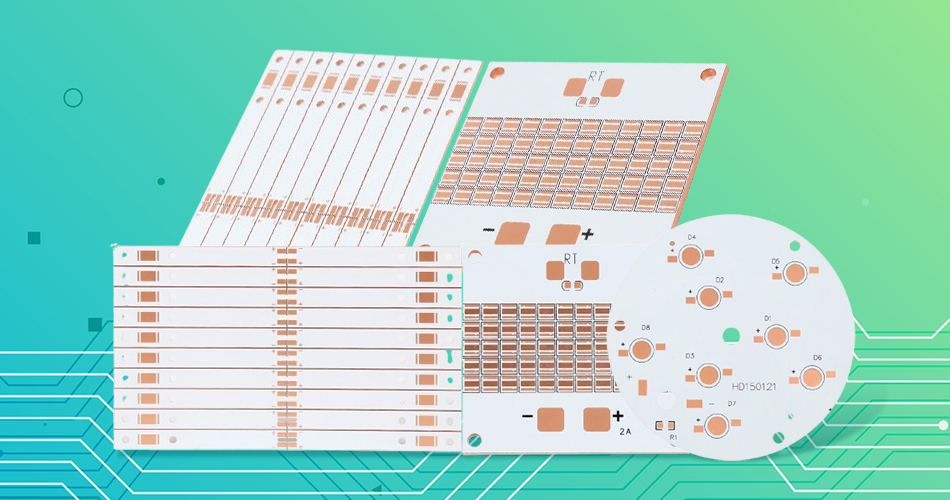

LED streetlights and industrial fixtures use sinkpad PCBs to cool LED arrays. The embedded sinkpad spreads heat evenly across the PCB, preventing hotspots that degrade LED brightness and lifespan. This integrated design also simplifies fixture assembly by eliminating the need for separate heatsink attachment.

The evolution of sinkpad PCBs is driven by the need for higher thermal performance and greater design flexibility:

- Composite Sinkpad Materials: Manufacturers are developing sinkpads using copper-tungsten or aluminum-silicon carbide composites, which combine high thermal conductivity with lower weight than pure copper—ideal for aerospace and automotive applications where weight is critical.

- 3D-Printed Sinkpad Structures: Additive manufacturing enables the creation of complex sinkpad geometries (e.g., internal micro-channels) that enhance heat dissipation. These 3D-printed sinkpads can be tailored to specific component heat profiles, further optimizing thermal transfer.

- Integrated Sensor Sinkpads: Some advanced designs embed temperature sensors directly within the sinkpad, providing real-time thermal feedback. This allows for dynamic cooling control, such as adjusting fan speed or power output to maintain optimal operating temperatures.

Sinkpad PCB is a game-changing thermal management solution that bridges the gap between PCB functionality and heat dissipation. By integrating a dedicated thermal pad into the board structure, it delivers lower resistance, space efficiency, and enhanced reliability compared to traditional approaches. As electronics continue to grow more power-dense and compact, sinkpad PCBs will remain essential for industries ranging from industrial automation to automotive and LED lighting. For engineers and manufacturers, adopting sinkpad PCB technology is key to developing products that balance high performance with long-term thermal reliability.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB