-

- PCB TYPE

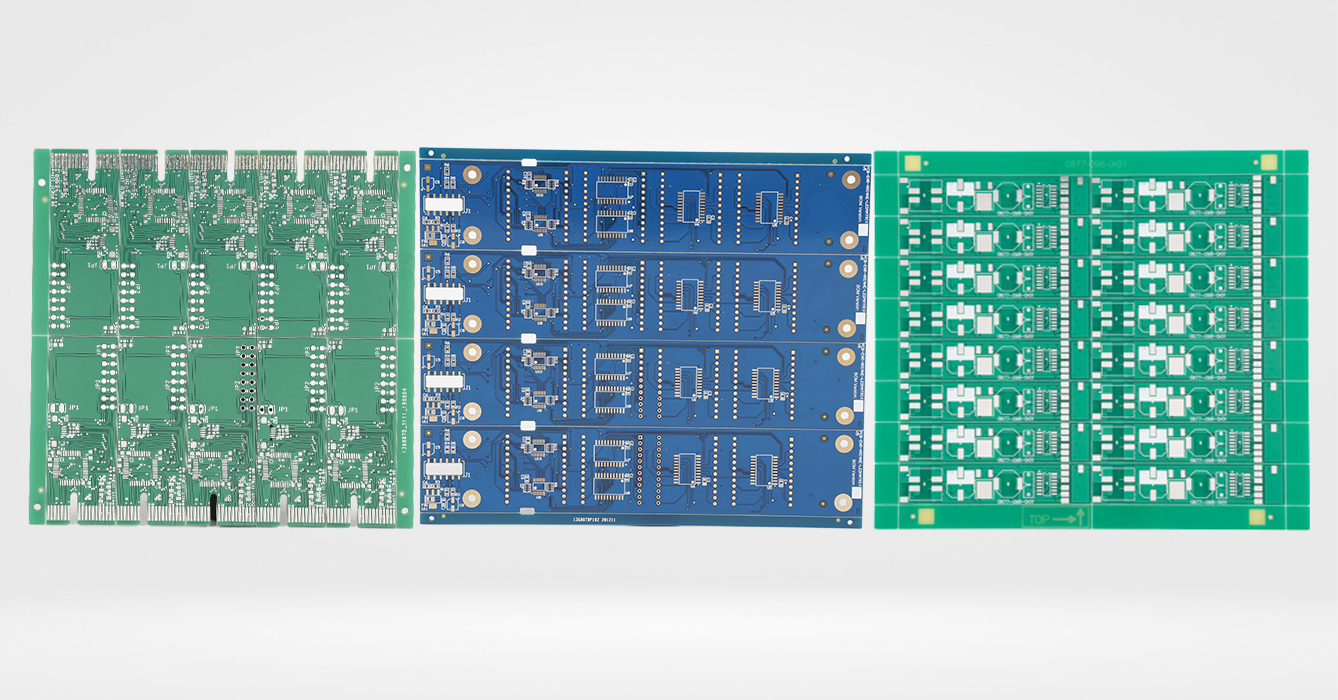

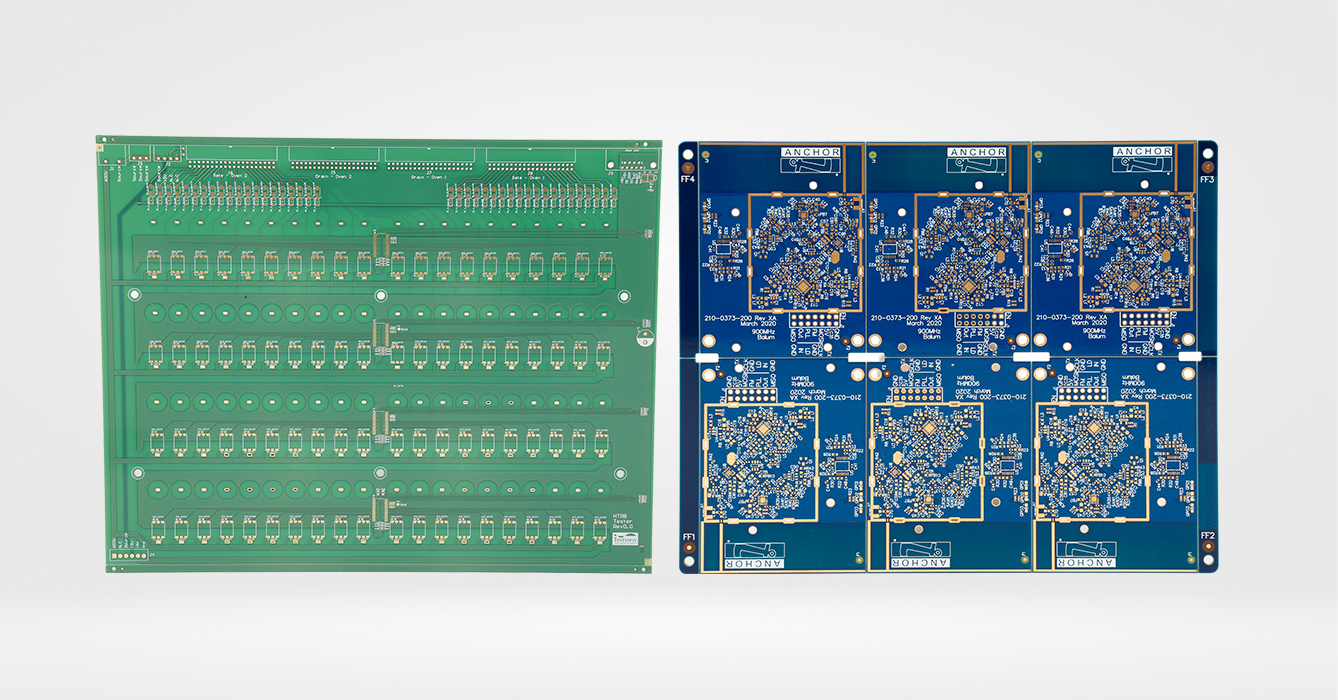

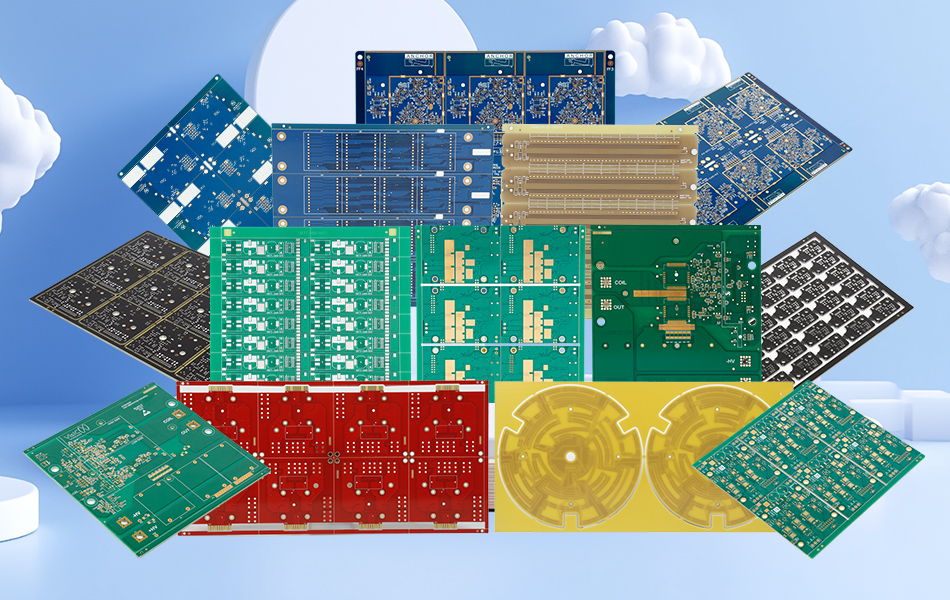

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 09. 2025, 16:13:06

In the vast landscape of printed circuit board (PCB) materials, the Standard FR4 PCB Material Type stands as the most widely used and recognized substrate, forming the backbone of countless electronic devices worldwide. Its enduring popularity stems from a unique blend of practicality, reliability, and cost-effectiveness, making it the default choice for engineers and manufacturers across industries. Unlike specialized high-performance variants, Standard FR4 is engineered for general-purpose applications, where its well-balanced properties—from mechanical stability to electrical insulation—meet the demands of everyday electronics without unnecessary complexity. This article explores the essence of Standard FR4, examining its composition, manufacturing journey, ideal applications, and enduring role in the electronics ecosystem, while highlighting why it remains indispensable in a world of advancing technology.

The Standard FR4 PCB Material Type is a glass-reinforced epoxy laminate designed to balance functionality and accessibility. The term "FR4" derives from its flame-retardant (FR) properties and classification under industry standards, where it is recognized as a workhorse material for non-specialized PCB designs.

At its core, Standard FR4 is defined by its suitability for conventional operating conditions: environments where temperatures remain moderate, signal speeds are not extreme, and mechanical stress is minimal. It is distinguished from high-temperature, low-dielectric, or halogen-free variants by its focus on versatility rather than niche performance. This focus ensures it remains cost-effective and easy to process, qualities that have solidified its position as the most produced PCB material globally.

Standard FR4’s performance is rooted in its composite structure, a carefully engineered blend of materials that work in harmony to deliver consistent results:

Epoxy Resin Matrix: The binding agent that holds the laminate together, the epoxy resin in Standard FR4 is chosen for its affordability, strong adhesion, and reliable curing properties. It forms a rigid, insulating network that prevents electrical leakage between conductive traces, ensuring basic signal integrity in low-to-moderate speed circuits.

Glass Fiber Reinforcement: Woven glass fibers provide mechanical strength and dimensional stability, preventing warpage during manufacturing and operation. The fibers are woven into a fabric that adds rigidity without excessive weight, ensuring the PCB maintains its shape under typical handling and operational stresses.

Flame Retardants: To meet safety standards, Standard FR4 incorporates additives that prevent sustained combustion. These flame retardants ensure the material self-extinguishes when exposed to fire, reducing risks in consumer and industrial electronics.

Copper Cladding: Thin sheets of copper are bonded to one or both sides of the laminate, forming the conductive pathways that carry electrical signals. The copper is later etched into specific patterns to create the circuit design, leveraging Standard FR4’s smooth surface for consistent etching results.

This combination of materials results in a substrate that is neither overly specialized nor underperforming, striking a practical balance for most electronic applications.

One of Standard FR4’s key advantages is its compatibility with established PCB manufacturing processes, which contributes to its low cost and widespread availability:

Prepreg Production: The process begins with creating prepreg—glass fiber fabric impregnated with uncured epoxy resin. This material is partially cured to a tacky state, allowing it to bond with other layers during lamination. Standard FR4 prepreg is formulated for easy handling and consistent flow, minimizing defects.

Lamination: Layers of prepreg are stacked with copper foil and pressed under heat to fully cure the epoxy, forming a solid laminate. Standard FR4’s resin system is designed to cure efficiently at moderate temperatures, reducing energy costs and production time compared to high-performance variants.

Drilling and Routing: Holes for vias (electrical connections between layers) and component leads are drilled using standard mechanical equipment. Standard FR4’s moderate hardness allows for clean drilling with common carbide tools, avoiding excessive wear.

Plating and Etching: Conductive copper is plated onto the walls of drilled vias to create electrical continuity between layers. The outer copper cladding is then etched using chemical processes to form the desired circuit pattern, a step simplified by Standard FR4’s uniform surface and resin-copper adhesion.

Finishing: A solder mask is applied to insulate copper traces and prevent short circuits, followed by silkscreen printing to add component labels. These final steps are streamlined for Standard FR4, as its surface properties work well with standard solder mask and ink formulations.

The efficiency of these processes ensures Standard FR4 PCBs can be produced in high volumes at low cost, making them accessible for everything from budget electronics to mass-produced consumer devices.

Standard FR4’s balanced properties make it ideal for applications that do not require specialized performance:

Consumer Electronics: Smartphones, tablets, and laptops rely on Standard FR4 for their main circuit boards. These devices operate in moderate temperatures and use low-to-moderate speed signals, well within Standard FR4’s capabilities. Its low cost is particularly valuable in high-volume consumer markets.

Office Equipment: Printers, scanners, and routers use Standard FR4 for control boards and connectivity modules. These devices generate minimal heat and operate at ambient temperatures, making the material’s thermal properties sufficient.

Home Appliances: Refrigerators, microwaves, and washing machines incorporate Standard FR4 PCBs in their control systems. These applications require basic electrical insulation and mechanical stability, which Standard FR4 provides reliably.

Low-Power Devices: Toys, remote controls, and small sensors often use single-layer or double-layer Standard FR4 PCBs. Their low power consumption and simple circuitry do not demand the advanced properties of specialized materials.

Educational and Prototyping: Standard FR4 is a staple in electronics education and prototyping, where its low cost and ease of use allow students and hobbyists to experiment without significant investment.

In each of these applications, Standard FR4 delivers the necessary performance without the added expense of high-temperature or low-dielectric variants, making it the practical choice.

Standard FR4’s enduring popularity is built on a set of advantages that align with the needs of most electronics manufacturers:

Cost-Effectiveness: Its simple composition and efficient manufacturing processes make Standard FR4 significantly cheaper than specialized materials, a critical factor for high-volume production and budget-conscious designs.

Widespread Availability: Standard FR4 is produced by countless manufacturers globally, ensuring a stable supply chain and short lead times. This availability reduces production delays and simplifies sourcing.

Ease of Processing: Compatibility with standard manufacturing equipment and techniques minimizes the need for specialized tools or expertise, lowering barriers to entry for small manufacturers and prototyping facilities.

Reliability in Conventional Conditions: In moderate temperatures and low-stress environments, Standard FR4 performs consistently, with minimal risk of failure. Its track record of reliability makes it a trusted choice for non-critical applications.

Regulatory Compliance: Standard FR4 meets basic safety and environmental standards, including flame retardancy requirements, ensuring it can be used in most global markets without additional certification hurdles.

While versatile, Standard FR4 is not suitable for all applications, as its general-purpose design leaves it ill-equipped for extreme conditions:

High-Temperature Environments: It struggles in settings where temperatures rise significantly, such as automotive engine compartments or industrial ovens. In these environments, the material may soften or degrade over time, compromising performance.

High-Speed or High-Frequency Signals: Applications requiring very fast data transmission—such as 5G infrastructure or advanced radar systems—demand materials with better signal integrity. Standard FR4’s electrical properties are insufficient for these high-frequency scenarios.

High-Power Devices: Equipment with high-power components, such as industrial motor drives or power amplifiers, generates significant heat that Standard FR4 cannot dissipate effectively, leading to hotspots and potential failure.

Harsh Chemical Exposure: Exposure to strong solvents, oils, or corrosive substances can degrade Standard FR4’s resin matrix, making it unsuitable for industrial settings with heavy chemical use.

Understanding these limitations is key to selecting the right material; Standard FR4 excels in conventional conditions but should be replaced with specialized variants when extremes are involved.

Standard FR4 is governed by industry standards that ensure consistency across manufacturers and markets:

Flame Retardancy: It meets global standards for fire safety, ensuring it self-extinguishes quickly to prevent fire spread in electronic devices. This compliance is critical for consumer safety and market access.

Mechanical and Electrical Benchmarks: Industry standards define minimum requirements for strength, insulation, and dimensional stability, ensuring Standard FR4 performs as expected across different suppliers.

Environmental Regulations: While not as strict as halogen-free variants, Standard FR4 meets basic environmental requirements in most regions, allowing it to be used in consumer products without violating common restrictions.

These standards provide confidence to designers and manufacturers, ensuring that Standard FR4 from different sources will perform consistently in their applications.

When designing with Standard FR4, engineers should focus on leveraging its strengths while mitigating its limitations:

Thermal Management: For low-power components, basic heat spreading—using copper pours or large ground planes—suffices to keep temperatures within safe limits. Avoid clustering heat-generating components to prevent hotspots.

Layout Simplicity: Standard FR4 works best with straightforward designs. Complex multi-layer boards or fine-pitch components may require more advanced materials, but simple layouts benefit from Standard FR4’s cost and ease of processing.

Environmental Protection: In humid or dusty environments, conformal coating can protect Standard FR4 from moisture and debris, extending its lifespan without the need for specialized laminates.

Cost Optimization: Use single or double-layer designs where possible, and avoid unnecessary features like blind or buried vias, which add complexity and cost without benefit in standard applications.

By aligning design choices with Standard FR4’s capabilities, engineers can create reliable, cost-effective PCBs for most conventional electronics.

Despite the rise of specialized materials, Standard FR4 is poised to remain a cornerstone of electronics manufacturing:

Continuous Improvement: Manufacturers are refining Standard FR4 formulations to enhance sustainability, using recycled glass fibers or bio-based resins without sacrificing performance. These tweaks align with global trends toward eco-friendly production.

Complementary Role: As specialized materials address niche needs, Standard FR4 continues to serve as the default for the majority of applications, a role unlikely to diminish given its cost and accessibility.

Adaptation to Emerging Markets: In developing regions and growing electronics sectors—such as IoT devices and low-cost sensors—Standard FR4’s affordability makes it the material of choice, driving continued demand.

Its ability to balance performance, cost, and availability ensures Standard FR4 will remain integral to electronics manufacturing for decades to come.

The Standard FR4 PCB Material Type is more than just a substrate; it is a testament to the value of practicality in engineering. By focusing on balance rather than specialization, it has become the backbone of countless electronic devices, from smartphones to home appliances. Its composition, manufacturing efficiency, and wide-ranging applications reflect a material designed to meet the needs of most users, not just the most demanding ones. While specialized materials will continue to advance, Standard FR4’s role as the workhorse of PCB manufacturing is secure, ensuring it remains indispensable in the ever-evolving world of electronics. For engineers and manufacturers, understanding and leveraging Standard FR4’s strengths is key to creating reliable, accessible, and cost-effective electronic systems.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB