-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Oct 29. 2025, 13:02:28

In today's fast-paced world, businesses are continuously seeking ways to stay ahead of the competition. One critical factor in achieving this is efficient and reliable manufacturing processes. This is especially true in the electronics industry, where precision, speed, and quality are paramount. Enter one-stop electronics manufacturing services, a solution that offers comprehensive support from concept to completion. But what exactly does this entail, and why should your business consider it?

One-stop electronics manufacturing services provide a full suite of solutions under one roof. This means that from the initial design phase to the final product delivery, all processes are streamlined and managed by a single entity. This approach not only simplifies the supply chain but also enhances communication and reduces production time.

Design and Prototyping: The journey begins with designing and prototyping. This phase is crucial as it sets the foundation for the entire project. By working with a single provider, businesses can ensure that their designs are optimized for manufacturability, saving time and resources down the line.

Procurement of Materials: A one-stop service provider manages the sourcing of materials, ensuring that only high-quality components are used. This reduces the risk of delays and defects, which can be costly and damaging to a brand's reputation.

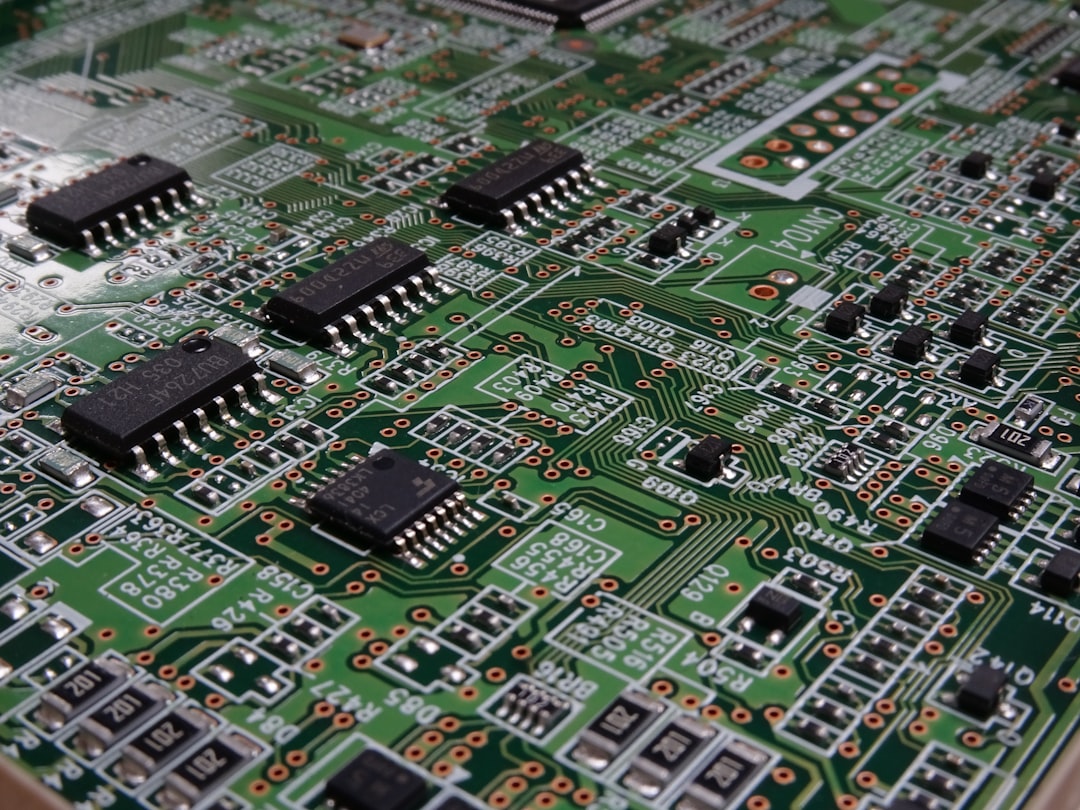

Assembly and Testing: Once the materials are procured, the next step is assembly and testing. One-stop services have the facilities and expertise to handle complex assemblies and rigorous testing, ensuring that the end product meets all specifications and quality standards.

Logistics and Delivery: Finally, a one-stop provider will handle the logistics and delivery of the finished product. This includes packaging, shipping, and even distribution, making it easier for businesses to focus on other critical areas.

Choosing a one-stop electronics manufacturing service offers numerous benefits that can significantly impact a business's bottom line.

By consolidating all manufacturing processes under one roof, businesses can eliminate the need to coordinate with multiple vendors. This leads to faster turnaround times and more efficient operations, as there is a single point of contact for all project-related queries and updates.

One-stop providers have stringent quality control measures in place at every stage of production. This ensures that all products meet industry standards and customer expectations. With comprehensive testing and inspection processes, businesses can have peace of mind knowing their products are of the highest quality.

While the initial investment in one-stop services may seem higher, the long-term savings are substantial. By reducing the number of suppliers and streamlining processes, businesses can lower overhead costs and avoid the pitfalls of miscommunication and delays.

One-stop electronics manufacturing services are designed to accommodate the needs of growing businesses. Whether you're launching a new product line or expanding into new markets, these services offer the flexibility to scale operations quickly and efficiently.

Selecting the right partner is crucial to the success of your manufacturing endeavors. Here are some factors to consider when evaluating potential providers:

Look for a provider with a proven track record in the electronics industry. Experience in handling projects similar to yours is invaluable, as it ensures they understand the unique challenges and requirements involved.

Ensure that the provider has the latest technology and capabilities to meet your production needs. This includes advanced machinery, skilled personnel, and a commitment to continuous improvement.

Research the provider's reputation within the industry. Customer reviews, testimonials, and case studies can provide insights into their reliability and the quality of their services.

Choose a provider that offers flexible and customizable solutions. Your business is unique, and a one-size-fits-all approach may not be suitable. The ability to tailor services to meet your specific requirements is essential.

Many industries benefit from one-stop electronics manufacturing services. Here are a few examples of how these services can be applied in various sectors:

In the highly competitive consumer electronics market, speed and quality are critical. One-stop services allow companies to bring products to market faster while maintaining high standards of quality.

The medical industry requires precision and adherence to strict regulations. One-stop manufacturing ensures that all components of a medical device are produced and tested to meet these stringent requirements.

With the rise of electric and autonomous vehicles, the demand for sophisticated automotive electronics has surged. One-stop providers offer the expertise and facilities needed to produce reliable and innovative automotive solutions.

One-stop electronics manufacturing services are a game-changer for businesses looking to streamline operations, improve quality, and reduce costs. By partnering with a reliable provider, companies can focus on innovation and growth, knowing that their manufacturing needs are in capable hands. Whether you're a startup or an established enterprise, the benefits of one-stop services are undeniable. Embrace this approach and position your business for success in the competitive electronics landscape.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB