-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Oct 29. 2025, 13:04:28

In today's fast-paced technological world, businesses need reliable partners to bring their electronic products to life. High-quality electronics manufacturing services (EMS) play a crucial role in transforming ideas into market-ready products. These services ensure that electronic components are manufactured with precision, reliability, and efficiency. Whether you're a startup developing a new gadget or an established company looking to streamline your production process, choosing the right EMS provider is essential.

Electronics Manufacturing Services encompass a range of processes that include designing, testing, building, distributing, and providing repair services for electronic components and assemblies. These services are vital for companies that wish to focus on their core competencies while outsourcing manufacturing to specialists.

Custom electronics manufacturing is all about tailoring production processes to meet specific client needs. This can involve small-scale prototypes or large-scale production runs. Customization allows businesses to create unique products that stand out in the market.

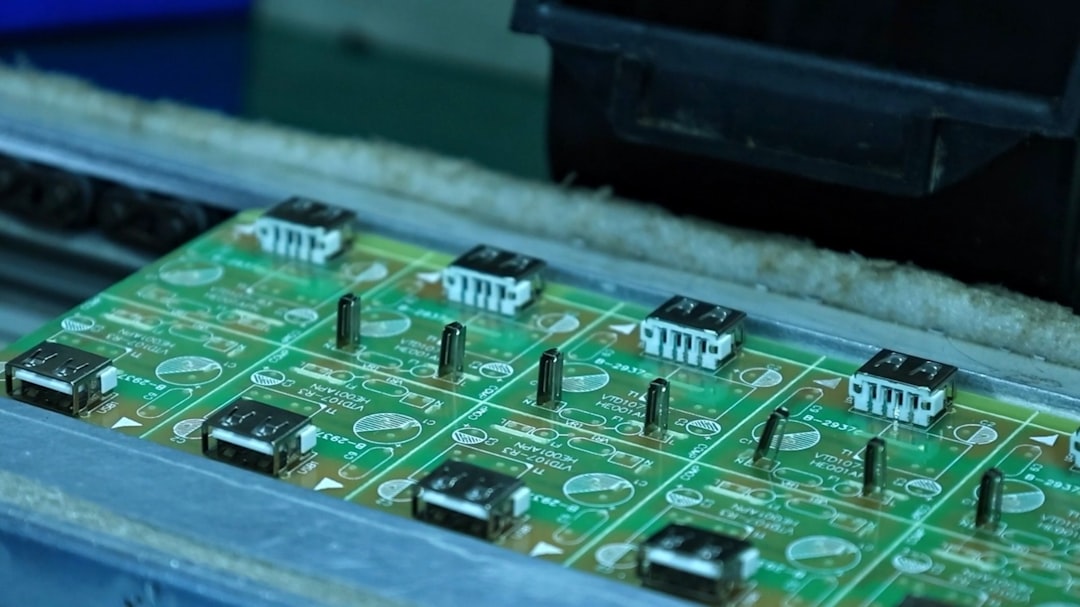

Prototype Development: Before mass production, prototypes are developed to test and validate the design. This step is crucial to identify any potential issues and ensure the product functions as intended.

Design Flexibility: Custom manufacturing services provide flexibility in design, allowing businesses to make adjustments based on market feedback or technological advancements.

Scalability: As demand for a product grows, custom manufacturing services can scale production to meet increased needs without compromising quality.

Choosing a high-quality EMS provider offers several benefits, including:

High-quality EMS providers adhere to stringent quality control processes. This means every component is tested and verified, ensuring reliability and longevity. Quality assurance is not just about meeting specifications but also about exceeding customer expectations.

Outsourcing manufacturing allows businesses to leverage the expertise and infrastructure of EMS providers, reducing the need for significant capital investments. This cost efficiency can be passed on to customers, resulting in competitive pricing.

With streamlined processes and skilled teams, high-quality EMS providers can reduce the time it takes for a product to go from concept to market. This speed is crucial in industries where technology and consumer preferences change rapidly.

Selecting the right EMS partner is a strategic decision that can impact your business's success. Here are some factors to consider:

Look for an EMS provider with a proven track record in your industry. Their technical expertise and experience can be invaluable in navigating complex manufacturing challenges.

Ensure that your EMS partner holds relevant quality certifications, such as ISO 9001 or IPC standards. These certifications demonstrate a commitment to quality and adherence to international manufacturing standards.

Your EMS provider should be able to adapt to your specific needs, offering customized solutions that align with your business goals. This flexibility can be a competitive advantage in a dynamic market.

Effective communication is key to a successful partnership. Choose an EMS provider that values transparency and collaboration, keeping you informed at every stage of the manufacturing process.

The electronics manufacturing industry is continually evolving. Here are some trends shaping its future:

The integration of automation and smart technologies is enhancing efficiency and precision in manufacturing processes. Automated systems can handle repetitive tasks, reducing errors and increasing productivity.

As environmental concerns grow, many EMS providers are adopting sustainable practices. This includes using eco-friendly materials, reducing waste, and optimizing energy consumption.

The Internet of Things (IoT) is revolutionizing electronics manufacturing. EMS providers are developing products with IoT capabilities, enabling seamless connectivity and improved user experiences.

High-quality electronics manufacturing services are pivotal for businesses aiming to deliver exceptional electronic products. By partnering with a reliable EMS provider, companies can focus on innovation and market growth, assured that their manufacturing needs are in expert hands. Whether you require custom electronics manufacturing or large-scale production, the right EMS partner can make all the difference.

In a world driven by technology, having a trusted manufacturing partner is not just an advantage—it’s a necessity. As you navigate the complexities of bringing electronic products to market, consider the impact that high-quality manufacturing services can have on your success.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB