-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Sep 29. 2025, 11:31:58

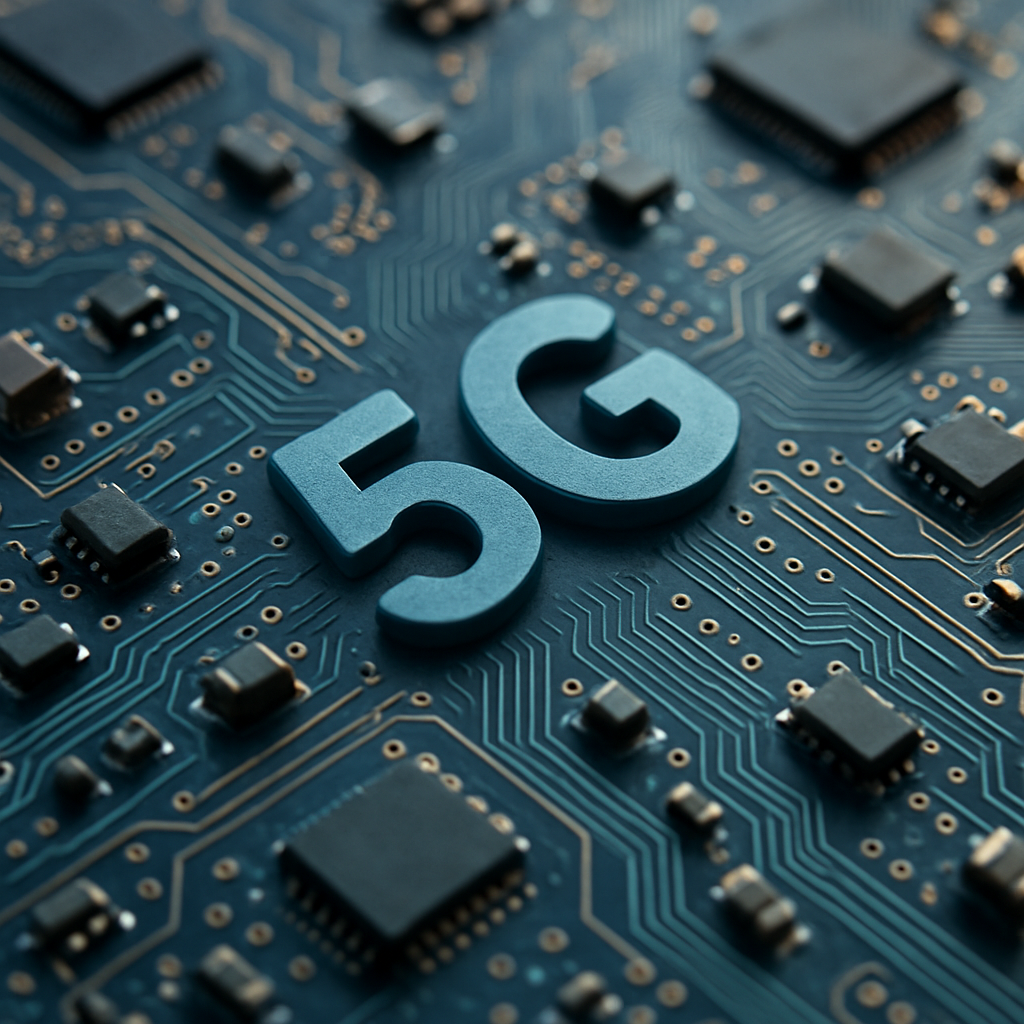

As technology continues to advance at a rapid pace, the demand for high-performance circuit boards has never been greater. One of the most exciting developments in recent years is the advent of 5G technology, which promises to revolutionize the way we connect and communicate. At the heart of this technological leap are 5G RF circuit boards, crucial components that enable faster and more reliable wireless communication.

To appreciate the role of a 5G RF circuit board manufacturer, it's important to understand what 5G RF circuit boards are and why they are essential. RF, or radio frequency, refers to the technology used to transmit and receive wireless signals. In the context of 5G, RF circuit boards are specially designed to handle the high frequencies and data rates associated with this new generation of wireless technology.

5G technology is set to offer speeds up to 100 times faster than its predecessor, 4G. This incredible speed is made possible by the use of higher frequency bands, which require advanced RF circuit boards to operate efficiently. These boards are responsible for processing and transmitting the complex signals necessary for 5G networks, making them a critical component in the 5G ecosystem.

Choosing the right manufacturer for 5G RF circuit boards is crucial for ensuring quality and performance. Here's why partnering with a specialized manufacturer can make all the difference:

Expertise in High-Frequency Design: 5G networks operate at much higher frequencies than previous generations. A specialized manufacturer has the expertise to design circuit boards that can handle these frequencies without signal loss or interference.

Cutting-Edge Materials and Techniques: The materials and techniques used in manufacturing 5G RF circuit boards are critical to their performance. Manufacturers specializing in 5G technology use advanced materials like low-loss laminates and precision etching techniques to ensure optimal signal integrity.

Customization and Flexibility: Every application has unique requirements, and a specialized manufacturer can offer customized solutions tailored to specific needs. Whether it's a particular board size, shape, or performance specification, a specialized manufacturer can deliver.

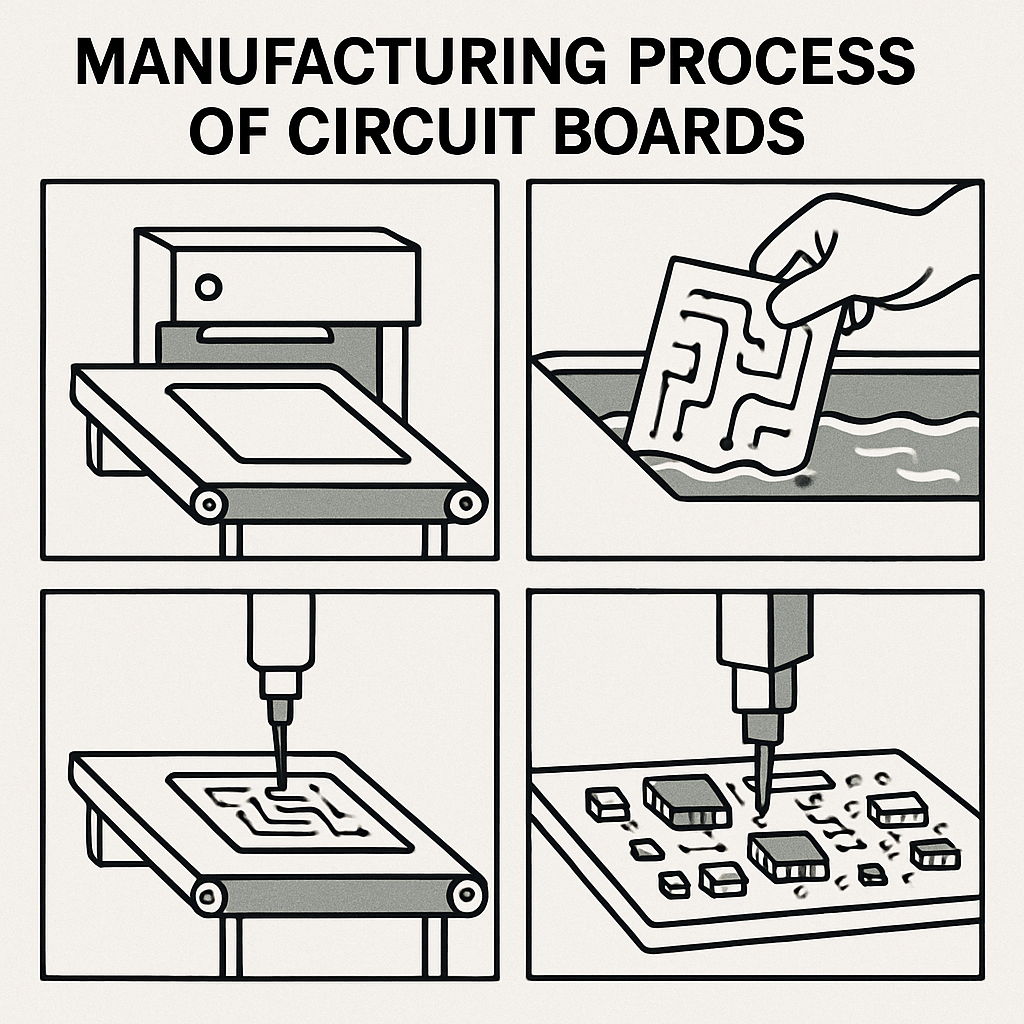

The process of manufacturing 5G RF circuit boards involves several key steps, each critical to ensuring the final product meets the necessary performance standards.

The first step in manufacturing a 5G RF circuit board is the design phase. Engineers use sophisticated software to create detailed designs that meet the specific requirements of the application. Once the design is finalized, a prototype is created to test its performance.

Choosing the right materials is essential for the performance of 5G RF circuit boards. Manufacturers select materials based on factors like dielectric constant, thermal stability, and signal loss characteristics. Low-loss materials are preferred to ensure minimal signal attenuation.

Manufacturing 5G RF circuit boards requires precision and attention to detail. The boards are fabricated using advanced techniques like photolithography and precision etching to create intricate patterns that allow for high-frequency operation.

Quality control is a crucial part of the manufacturing process. Each board undergoes rigorous testing to ensure it meets performance standards. Tests include signal integrity testing, thermal testing, and reliability testing to ensure the board can withstand real-world operating conditions.

The applications of 5G RF circuit boards are vast and varied, reflecting the transformative potential of 5G technology.

One of the most significant applications of 5G RF circuit boards is in telecommunications. These boards are used in base stations and network infrastructure to enable high-speed data transmission and low-latency communication.

5G technology is set to revolutionize the automotive industry by enabling advanced features like autonomous driving, vehicle-to-vehicle communication, and enhanced navigation systems. RF circuit boards are crucial for these applications, providing the necessary connectivity and processing power.

The Internet of Things is another area poised for transformation with 5G technology. RF circuit boards are used in IoT devices to facilitate seamless connectivity and data exchange, enabling smart homes, smart cities, and industrial automation.

When selecting a 5G RF circuit board manufacturer, it's important to consider factors like expertise, experience, and the ability to deliver customized solutions. Partnering with a manufacturer that understands the unique challenges and requirements of 5G technology can ensure the success of your project.

Reputation and Experience: Look for a manufacturer with a proven track record in producing high-performance RF circuit boards.

Technological Capabilities: Ensure the manufacturer uses cutting-edge technology and techniques to deliver superior products.

Customer Support: A manufacturer that offers excellent customer support can provide valuable assistance throughout the design and manufacturing process.

5G RF circuit boards are at the forefront of the next generation of wireless technology, enabling faster and more reliable communication across a wide range of applications. By choosing a specialized 5G RF circuit board manufacturer, you can ensure the quality, performance, and reliability of your products, paving the way for innovation and success in the era of 5G.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB