-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Sep 11. 2025, 09:50:30

In the world of electronics, Printed Circuit Boards (PCBs) are the backbone of any device. Whether you're designing a simple gadget or a complex electronic system, the quality of your PCB can significantly impact the performance and reliability of your product. That's why choosing the right PCB fabrication manufacturer is crucial. In this guide, we'll walk you through the essential factors to consider when selecting a PCB manufacturer to ensure you get the best quality boards for your needs.

Before diving into how to choose a manufacturer, it's essential to understand what PCB fabrication involves. PCB fabrication is the process of creating the physical board that will hold and connect the electronic components of your device. This process includes designing the layout, choosing the materials, and assembling the components.

Quality in PCB fabrication is non-negotiable. A low-quality PCB can lead to device malfunctions, reduced lifespan, and increased costs due to repairs and replacements. Ensuring high-quality standards in PCB manufacturing is vital to the success of your electronic products.

When selecting a PCB fabrication manufacturer, several critical factors must be considered. These factors will help ensure that you choose a manufacturer that meets your specific needs and delivers quality products.

One of the first things to look for in a PCB manufacturer is their experience and expertise in the field. An experienced manufacturer will have a proven track record of producing high-quality PCBs and will be familiar with the latest industry standards and technologies.

Consider the range of services offered by the manufacturer. Some manufacturers provide a full range of services from PCB design to assembly, while others may only offer fabrication. Choosing a manufacturer that offers comprehensive PCB assembly services can save you time and hassle, ensuring that your boards are ready for use as soon as they arrive.

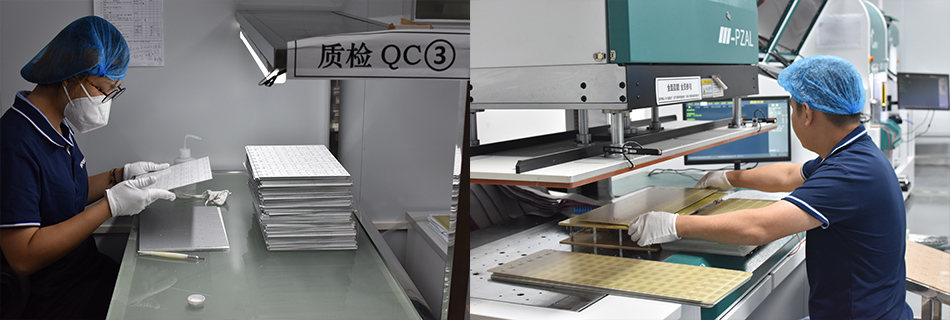

Quality control is another crucial factor to consider. Ask potential manufacturers about their quality control processes and certifications. A reputable manufacturer will have strict quality control measures in place to ensure that each board meets the highest standards.

Different projects have different requirements, and you may need a manufacturer that can customize their services to meet your specific needs. Whether it's a unique board size or special material requirements, make sure the manufacturer can accommodate your requests.

In the fast-paced world of electronics, time is often of the essence. Consider the manufacturer's turnaround time and ensure it aligns with your project deadlines. A manufacturer with a quick turnaround time can help you bring your product to market faster.

While cost shouldn't be the only factor you consider, it's certainly an important one. Compare quotes from different manufacturers and weigh them against the quality of services offered. Remember, the cheapest option isn't always the best if it compromises quality.

Technology plays a significant role in PCB fabrication. From automated assembly lines to cutting-edge design software, the use of advanced technology can greatly enhance the quality and efficiency of PCB manufacturing.

Manufacturers that employ advanced techniques such as surface mount technology (SMT) and through-hole technology (THT) can offer more reliable and precise PCBs. These techniques allow for greater component density and more complex circuit designs.

The use of advanced design software is another indicator of a quality manufacturer. Design software helps ensure that the layout of the PCB is optimized for performance and reliability.

Good communication is essential when working with a PCB fabrication manufacturer. Clear communication ensures that your requirements are understood and met, reducing the risk of errors and delays.

Before starting the manufacturing process, establish clear requirements and specifications for your PCB. This includes materials, dimensions, and any special features or capabilities required.

Stay in touch with the manufacturer throughout the fabrication process. Regular updates and feedback can help catch any potential issues early, ensuring that the final product meets your expectations.

Choosing the right PCB fabrication manufacturer is a critical step in the development of any electronic product. By considering factors such as experience, range of services, quality control, and technology, you can select a manufacturer that will deliver high-quality PCBs that meet your needs. Remember, the right manufacturer is not just a supplier but a partner in your product's success. With careful consideration and clear communication, you can ensure that your PCBs are of the highest quality, setting the foundation for reliable and successful electronic devices.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB