-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Sep 11. 2025, 09:52:36

Before diving into the selection process, it's essential to have a clear understanding of your PCB requirements. This includes the type of PCB you need, the complexity of the design, the materials required, and the volume of production. Having a well-defined set of requirements will not only streamline your search for a manufacturer but also aid in communicating your needs effectively. It’s important to consider both the technical specifications and the functional requirements of your project to ensure that the chosen manufacturer can meet your expectations.

PCBs come in various types, each suited for different applications:

Single-sided PCBs - These are the simplest type of PCB with components on one side of the board and a conductive layer on the other. They are cost-effective and used for low-density designs. Due to their simplicity, they are ideal for basic electronic devices and prototypes where complex circuitry is not required.

Double-sided PCBs - These have components and conductive layers on both sides, suitable for more complex circuits. They allow for more connections and are widely used in consumer electronics, offering a balance between complexity and cost.

Multilayer PCBs - These consist of multiple layers of conductive material, allowing for high-density designs used in advanced electronics. They are essential for modern devices like smartphones and medical equipment, where space is limited, and performance is critical.

Rigid, Flexible, and Rigid-Flex PCBs - Depending on the application, you might need rigid, flexible, or a combination of both (rigid-flex) to fit within the physical constraints of the device. Flexible PCBs are used in applications where the board needs to bend, such as in wearable technology, while rigid-flex boards provide structural stability with flexibility.

Determine whether you need a custom PCB design or a standard one. Custom PCBs offer flexibility in design and are tailored to specific requirements but may come at a higher cost. They are ideal for specialized applications where off-the-shelf solutions do not meet the exact needs. Standard PCBs are pre-designed and are generally more affordable, making them suitable for common applications with less stringent requirements. Evaluating the trade-offs between customization and cost is essential to making an informed decision that aligns with your project goals.

Once you understand your needs, evaluate potential PCB manufacturers based on several critical factors. The choice of a manufacturer can greatly influence the success of your project, impacting everything from production timelines to the final product quality.

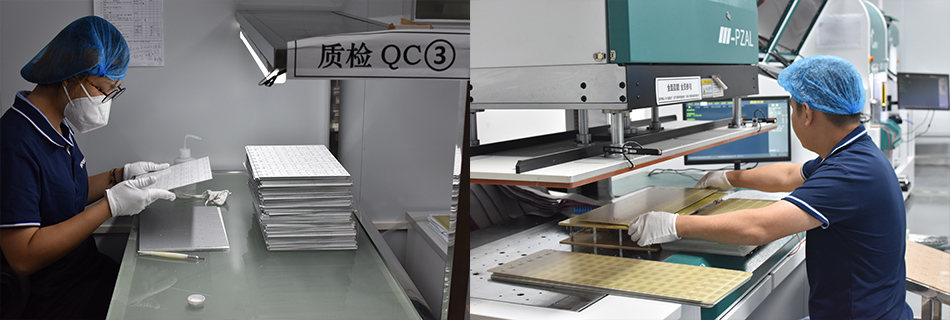

Quality is paramount when it comes to PCBs. Look for manufacturers with robust quality assurance processes. Certifications like ISO 9001 or IPC standards are good indicators of a company's commitment to quality. These certifications ensure that the manufacturer adheres to international standards for quality management, reducing the risk of defects and failures. Additionally, inquire about their testing procedures to ensure that each board meets your specifications and performance criteria.

Experience matters. Manufacturers with years of experience in the industry are likely to have refined their processes and developed expertise in handling complex designs. Check if they have worked on projects similar to yours, as this can provide valuable insights and reduce the learning curve. An experienced manufacturer will be better equipped to handle potential challenges and provide guidance on design optimizations, leading to a more efficient production process.

Evaluate the technological capabilities of the manufacturer. This includes their ability to handle different types of PCBs, advanced manufacturing processes, and cutting-edge equipment. A manufacturer with state-of-the-art technology can offer better precision and quality. Advanced capabilities such as laser drilling, automated optical inspection, and 3D printing can enhance the production process, enabling the creation of complex designs with high accuracy.

Consider the turnaround time offered by the manufacturer. Faster turnaround times can be crucial, especially if you're working on a tight schedule. However, ensure that speed does not compromise quality. Discuss the production schedule in detail and set realistic expectations for delivery timelines. A reliable manufacturer should provide a balance between speed and quality, offering flexibility to accommodate urgent requirements without compromising standards.

Cost is always a factor. Obtain quotes from multiple manufacturers and compare them. Remember that the cheapest option is not always the best. Consider the value offered in terms of quality, reliability, and service. A slightly higher upfront cost may be justified by superior quality and support, reducing the likelihood of costly rework or failures in the field. Evaluate the long-term implications of cost decisions to ensure the sustainability of your project.

Good customer service is essential for a smooth manufacturing process. Choose a manufacturer that offers excellent communication, transparency, and support throughout the project. Responsive customer service can help address issues promptly and provide updates on production progress. Look for a partner who values collaboration and is willing to work with you to achieve your project goals.

The manufacturer's locati0n can impact shipping times and costs. Local manufacturers may offer faster shipping and easier communication, while overseas manufacturers might provide cost advantages. Weigh the pros and cons based on your priorities. Consider factors such as import/export regulations, language barriers, and cultural differences that may affect the collaboration. Selecting a manufacturer whose locati0n aligns with your logistical needs can enhance the overall efficiency of the project.

In addition to manufacturing, consider whether the manufacturer offers PCB assembly services. This involves placing components onto the PCB, which can be a time-consuming task if done separately. Integrated services can save time and ensure better quality control. By choosing a manufacturer that offers both fabrication and assembly, you can streamline the production process and reduce the risk of compatibility issues between different service providers.

Surface Mount Technology (SMT) vs. Through-Hole Technology (THT)

Understand the types of assembly technologies offered:

Surface Mount Technology (SMT) - Components are mounted directly onto the surface of the PCB. SMT is suitable for high-density designs and offers faster production. It is the preferred method for most modern electronics due to its efficiency and ability to support compact, lightweight designs.

Through-Hole Technology (THT) - Components are inserted through holes in the PCB and soldered in place. THT is robust and better suited for components that require mechanical strength. It is often used in applications where durability and reliability are more critical than size constraints.

Testing and Quality Control

Ask about the testing and quality control measures the manufacturer employs during assembly. Functional testing, in-circuit testing, and automated optical inspection are some methods used to ensure the assembly is error-free. These testing procedures are essential to verify that the final product functions as intended and meets all design specifications. A manufacturer with rigorous quality control processes can provide greater assurance of product reliability and performance.

Consider the story of a small tech startup that needed a reliable PCB manufacturer for their innovative wearable device. By prioritizing quality, technological capabilities, and customer service, they partnered with a manufacturer who not only delivered high-quality PCBs but also provided valuable design insights that improved the final product. This collaboration resulted in enhanced functionality and reduced production costs, showcasing the importance of selecting a manufacturer who can act as a true partner. This partnership was crucial in bringing their product to market successfully, demonstrating that the right manufacturer can significantly impact the trajectory of a project.

Choosing the right PCB manufacturer requires careful consideration of various factors, from quality and experience to cost and logistics. By understanding your needs and evaluating potential partners based on these criteria, you can make an informed decision that ensures the success of your project. Whether you're looking for a simple single-sided PCB or a complex multilayer design, the right manufacturer will be a valuable partner in your journey from concept to reality. Investing time in selecting the right partner can lead to long-term benefits, including improved product performance, cost savings, and a more streamlined production process.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB