-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Sep 17. 2025, 10:06:04

Printed Circuit Boards (PCBs) are the backbone of modern electronic devices. Whether you're designing a simple gadget or a complex electronic system, choosing the right PCB manufacturer is crucial. This decision affects not only the quality of your product but also the efficiency of your production process and, ultimately, your bottom line.

In this guide, we'll walk you through the essential factors to consider when selecting a PCB manufacturer to meet your specific needs.

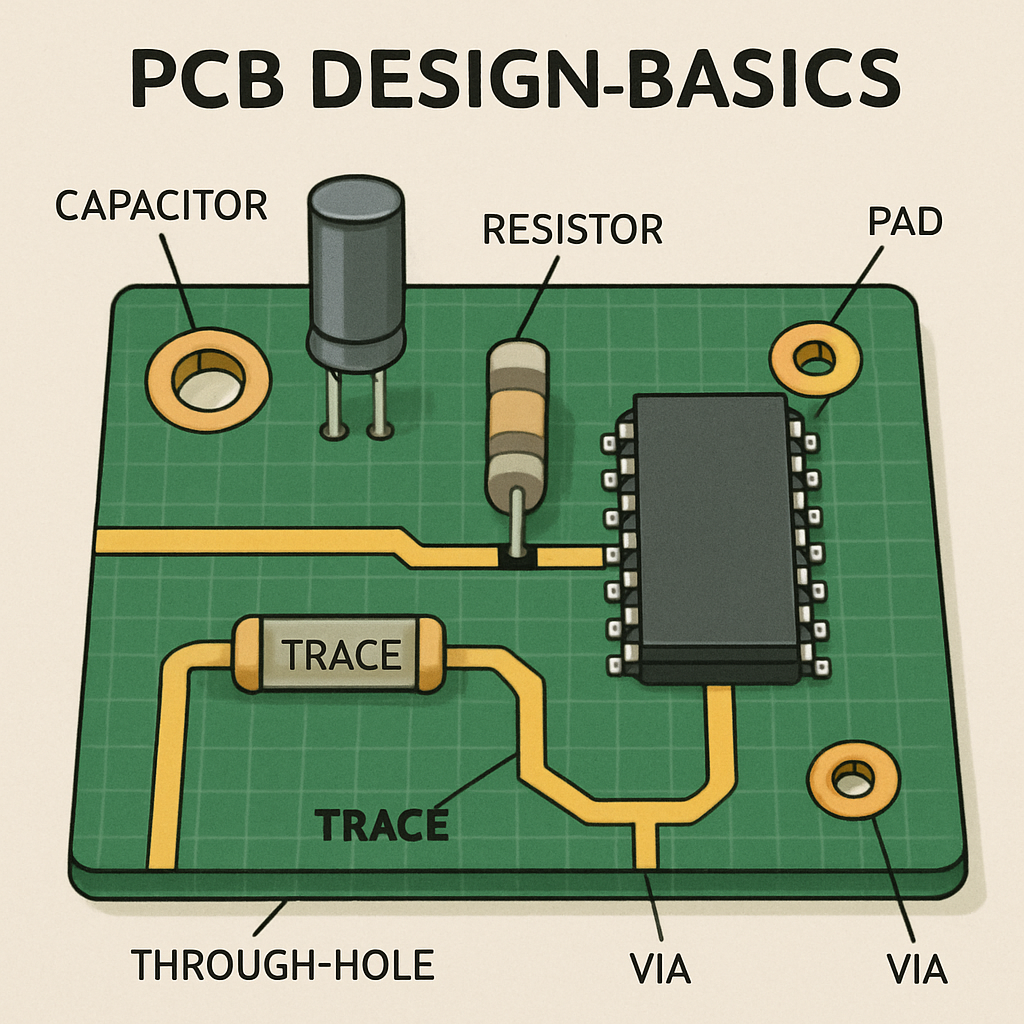

Before diving into the selection process, it's essential to understand the basics of PCB design and assembly. PCBs are used to mechanically support and electrically connect electronic components. They are made up of layers, including a substrate, traces, silkscreen, and solder mask.

The design phase is critical because it determines the layout and functionality of the board. A good design will ensure the reliability of the finished product. When choosing a PCB manufacturer, consider their capability to handle your specific design requirements, whether it's a simple single-layer board or a complex multi-layer design.

PCB assembly refers to the process of soldering components onto the board. This step requires precision and expertise. The manufacturer must have state-of-the-art equipment and skilled technicians to ensure high-quality assembly.

Selecting the right PCB manufacturer involves more than just finding a company that can produce your boards. Here are the key factors to consider:

Look for a manufacturer with a proven track record in producing PCBs similar to your design. Experience in your specific industry can be a significant advantage, as they will be familiar with industry standards and requirements.

Quality is non-negotiable when it comes to PCBs. Ensure the manufacturer adheres to international quality standards such as ISO 9001, IPC-A-610, and RoHS compliance. These certifications indicate that the manufacturer follows strict quality control measures.

Assess the manufacturer's production capabilities, including the types of PCBs they can produce, the number of layers, and their ability to handle complex designs. Also, inquire about their capacity to scale production if your demand increases.

Modern PCB manufacturing relies heavily on technology. Check if the manufacturer uses the latest equipment and software for design, production, and testing. Advanced machinery ensures precision and high-quality output.

Time is often of the essence in electronics production. Discuss the manufacturer's lead times and their ability to meet your deadlines. A reliable manufacturer should offer a balance between speed and quality.

While cost shouldn't be the only deciding factor, it is crucial to your business's bottom line. Request quotes from multiple manufacturers and compare their pricing structures. Be cautious of prices that are significantly lower than the industry average, as they may indicate compromised quality.

Good customer support is vital throughout the manufacturing process. Choose a manufacturer that offers excellent communication and support, from the initial inquiry to after-sales service. They should be responsive and willing to address any concerns or issues promptly.

Once you've identified potential manufacturers, it's time to evaluate them more thoroughly.

Ask for samples of their previous work. This will give you a firsthand look at their quality and attention to detail. Examine the samples for precision in design, soldering quality, and overall craftsmanship.

If possible, arrange a visit to the manufacturer's facility. This allows you to see their operations, equipment, and quality control processes firsthand. A site visit can provide valuable insights into their capabilities and reliability.

Reach out to other companies that have worked with the manufacturer. Their feedback can offer insights into what you can expect in terms of service, quality, and reliability. Online reviews and testimonials can also be helpful in assessing their reputation.

Choosing a PCB manufacturer isn't just about finding a supplier; it's about building a partnership. A good manufacturer will work with you to refine your designs, improve efficiency, and reduce costs. They should be willing to collaborate and offer suggestions that enhance your product's performance and manufacturability.

After evaluating all these factors, you should have a clear picture of which manufacturer is the best fit for your needs. Remember, the right choice will help ensure the success of your electronic products by providing high-quality, reliable PCBs.

Selecting the right PCB manufacturer is a critical step in bringing your electronic designs to life. By considering factors such as experience, quality standards, capabilities, and support, you can make an informed decision that aligns with your business goals.

Remember, a reliable PCB manufacturer is more than just a vendor—they're a partner in your success. Take the time to choose wisely, and you'll benefit from a smooth production process and high-quality products.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB