-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Sep 04. 2025, 19:37:02

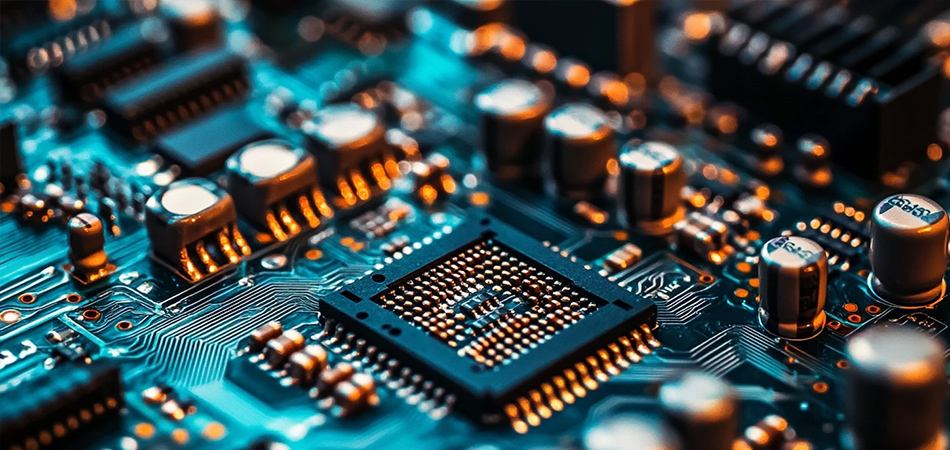

Turnkey PCB Assembly Solution integrates electronics manufacturing from design to delivery under one provider, replacing fragmented processes with end-to-end coordination. This approach reduces complexity, shortens time-to-market, and ensures quality—critical for industries like automotive, medical devices, and consumer electronics. By outsourcing assembly, businesses focus on innovation while leveraging experts for reliable, scalable production.

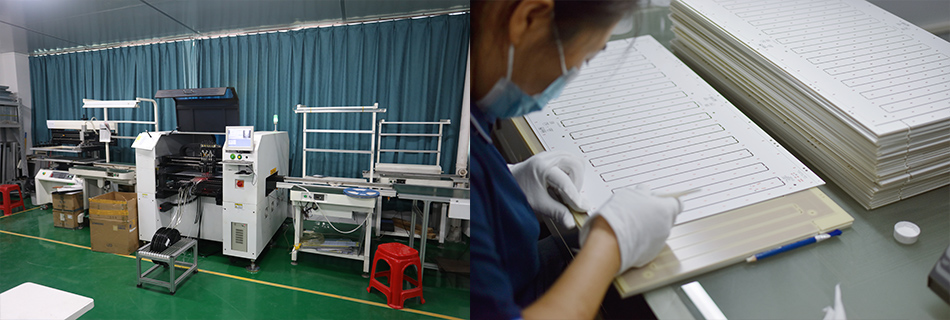

Design & Engineering: DFM analysis optimizes designs for manufacturability, with prototyping and material guidance to avoid rework.

Component Sourcing: Global networks secure authentic parts, with JIT inventory and contingency plans to mitigate shortages.

Fabrication & Assembly: Coordinated PCB production and mixed-technology assembly (SMT, through-hole) ensure compatibility and precision.

Quality Control: In-process inspections (AOI, X-ray), functional tests, and reliability checks (thermal, vibration) validate performance.

Final Assembly: Box build integration, custom packaging, and traceable documentation deliver ready-to-ship products.

Logistics & Support: Global shipping, warranty services, and flexible scaling adapt to demand fluctuations.

Automotive: Ensures IATF 16949 compliance with traceable supply chains, high-volume efficiency, and extreme environment testing.

Medical Devices: Meets FDA/CE standards via cleanroom assembly, regulatory documentation, and flexible low-volume production.

Consumer Electronics: Accelerates launches with rapid prototyping, cost-optimized components, and scalable mass production.

Key criteria include: industry certifications (IATF 16949, ISO 13485), resilient supply chains, technical capabilities (fine-pitch assembly, advanced testing), robust quality systems, scalability, and transparent communication.

Automation (AI inspection, cobots), sustainability (eco-materials, energy efficiency), Industry 4.0 (digital twins, IoT tracking), and miniaturization (micro-assembly, flexible electronics) are reshaping turnkey solutions.

Turnkey PCB Assembly streamlines manufacturing by unifying processes, delivering efficiency and quality across industries. As trends like automation and sustainability advance, it remains a strategic tool for competitiveness, letting businesses balance innovation with reliable production.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB