-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Sep 03. 2025, 14:37:51

Choosing the right PCB (Printed Circuit Board) manufacturer is crucial for the success of your electronic projects. With many manufacturers available, selecting the best one can feel overwhelming. However, by understanding the key factors involved, you can make an informed decision that meets your specific needs. In this article, we'll break down the essentials of choosing a PCB manufacturer and help guide you through the process.

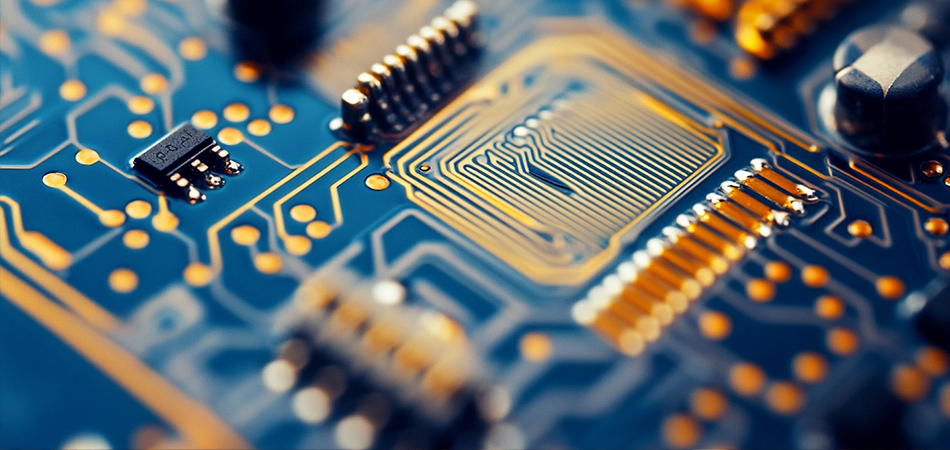

Printed Circuit Boards are the backbone of all electronic devices. They connect various electronic components through conductive pathways. A reliable PCB manufacturer ensures the board's quality, affecting the performance and reliability of your electronic products.

PCB assembly is the process of soldering electronic components onto a PCB. It includes different techniques such as surface mount technology (SMT) and through-hole technology. The choice of technology depends on your project requirements and the expertise of the manufacturer.

Electronic manufacturing involves several stages, from design and prototyping to production and testing. A good PCB manufacturer offers comprehensive services, ensuring that your product is built to specification and meets industry standards.

Choosing the right manufacturer involves evaluating several key factors. Here's what you should consider:

Quality assurance is paramount in PCB manufacturing. Look for manufacturers with certifications such as ISO 9001, which demonstrate a commitment to maintaining high-quality standards. Check if they have a robust testing process to ensure the reliability of their products.

The experience of a manufacturer can significantly influence the quality of your PCB. Experienced manufacturers are more likely to have encountered various challenges and developed effective solutions. Look for those with a proven track record in your specific industry.

Different projects require different specifications. A manufacturer with strong customization capabilities can tailor their services to meet your unique requirements. This might include custom board sizes, materials, or component placements.

Time is often a critical factor in electronic manufacturing. Evaluate the manufacturer's production lead times and their ability to meet deadlines. Delays in production can lead to increased costs and missed market opportunities.

While cost should not be the only determining factor, it is certainly important. Compare quotes from multiple manufacturers, considering both the price and the value they offer. Remember that the cheapest option is not always the best in terms of quality and reliability.

To choose the right PCB manufacturer, you must evaluate their capabilities thoroughly. Here's how to do it effectively:

Look into the technical capabilities of the manufacturer. Can they handle the complexity of your design? Do they offer advanced technologies like multi-layer PCBs or flexible boards? Ensure they have the technical expertise to deliver your project successfully.

Ask for examples of past projects similar to yours. This will give you insight into their experience and ability to meet your requirements. Customer testimonials and case studies can also provide valuable information.

Ensure the manufacturer complies with industry standards and regulations. This includes adherence to environmental standards like RoHS (Restriction of Hazardous Substances) and other regulatory requirements relevant to your industry.

A strong relationship with your PCB manufacturer can lead to better communication and project outcomes. Here's how to foster a positive partnership:

Ensure that the manufacturer is responsive and communicative. Open lines of communication help prevent misunderstandings and ensure that any issues are quickly addressed.

Trust is essential in any business relationship. Choose a manufacturer that is transparent about their processes and willing to provide regular updates on your project's progress.

Consider the potential for a long-term partnership. A manufacturer that understands your business and its needs can offer better service and support in future projects.

Choosing the right PCB manufacturer involves careful consideration of quality, experience, customization, and cost. By evaluating these factors and building a strong relationship with your manufacturer, you can ensure the success of your electronic projects. Make an informed decision today to lay the groundwork for your future innovations.

Remember, the right PCB manufacturer is not just a service provider, but a partner in your journey to creating reliable and cutting-edge electronic products. Take the time to research and choose wisely, and your efforts will be rewarded with superior results.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB