-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 25. 2025, 11:57:02

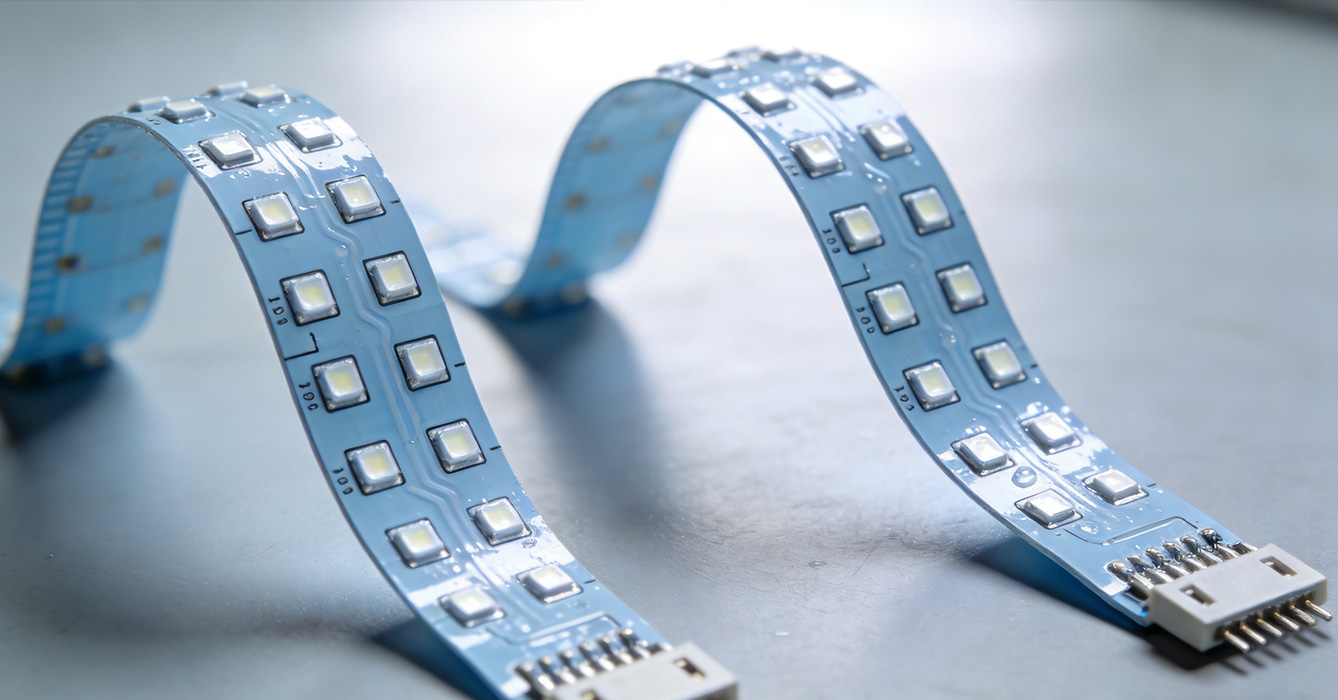

In lighting applications across harsh and humid environments—from outdoor landscapes and marine engineering to underground corridors and agricultural greenhouses—reliability and durability are critical requirements. The Waterproof LED FPCB Lighting Board has emerged as a game-changing solution, combining the flexibility of flexible printed circuit boards (FPCB) with advanced waterproof technology. Unlike traditional rigid PCB lighting boards that are prone to failure in humid conditions and lack adaptability to irregular surfaces, this innovative lighting board delivers stable performance in moisture-rich environments while fitting complex shapes. For engineers, project managers, and facility operators, the Waterproof LED FPCB Lighting Board is a core component to ensure long-term lighting stability, reduce maintenance costs, and expand the application scope of LED lighting. This article explores the core value, scenario-specific applications, implementation guidelines, and future trends of the Waterproof LED FPCB Lighting Board, highlighting its pivotal role in harsh environment lighting solutions.

Traditional lighting boards face significant limitations when applied in harsh humid environments, failing to meet the basic requirements of reliability and longevity. Rigid PCB lighting boards, the most common traditional option, have poor flexibility and cannot adapt to curved or irregular installation surfaces—such as curved building facades, pipeline exteriors, or marine equipment contours. More critically, ordinary rigid PCBs lack effective waterproof protection; moisture easily penetrates the circuit layers, leading to insulation degradation, short circuits, and significant reductions in LED lifespan. In high-humidity regions or underwater applications, traditional lighting boards often experience failure rates exceeding 30% within a year, resulting in frequent maintenance and operational disruptions.

Another key drawback is the inefficiency of traditional waterproofing modifications. To enhance moisture resistance, traditional rigid PCBs often require additional sealing structures or waterproof coatings, which increase product weight, reduce heat dissipation efficiency, and raise production costs. These modified solutions also struggle with long-term reliability—seals degrade over time due to temperature cycles and environmental erosion, leading to gradual loss of waterproof performance. The Waterproof LED FPCB Lighting Board addresses these gaps through integrated waterproof design and inherent flexibility, providing a more reliable and adaptable lighting solution for harsh humid environments.

The Waterproof LED FPCB Lighting Board offers three unique advantages that make it superior to traditional lighting boards in harsh humid environments:

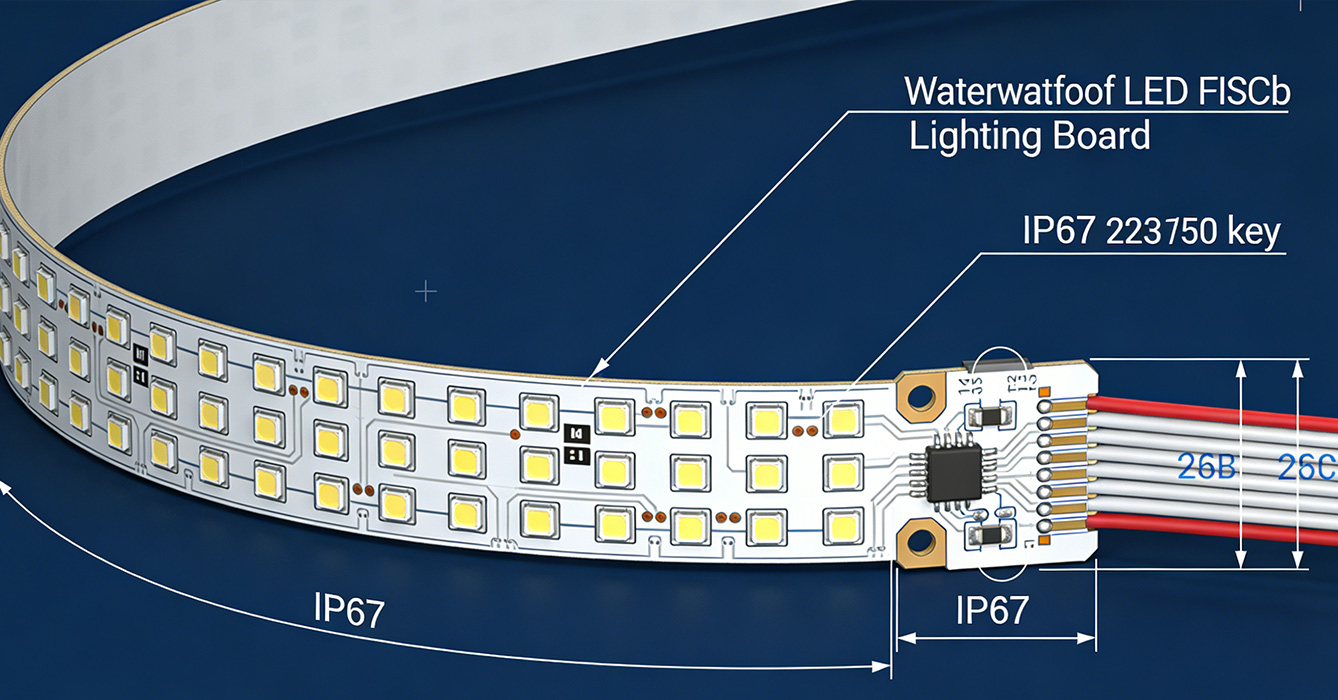

- Integrated waterproof reliability: Equipped with advanced waterproof coatings and sealed circuit designs, the Waterproof LED FPCB Lighting Board effectively blocks moisture, dust, and corrosive substances from penetrating the circuit. This integrated protection eliminates the need for additional waterproof modifications, ensuring stable performance in high-humidity, rainy, or even underwater environments. Its resistance to corrosion also makes it suitable for salt-rich marine environments and industrial areas with chemical vapors.

- Flexible adaptability to complex shapes: Leveraging the inherent flexibility of FPCB, this lighting board can be bent, twisted, or folded to fit irregular surfaces—such as curved building exteriors, pipeline lighting, and contoured marine equipment. This flexibility expands the application scope of LED lighting, enabling creative and functional lighting designs that are impossible with rigid PCB boards. It also simplifies installation by conforming to the shape of the installation surface, reducing the need for custom brackets.

- Efficient heat dissipation and long lifespan: Most Waterproof LED FPCB Lighting Boards use high-temperature-resistant polyimide substrates, which provide excellent thermal conductivity. Efficient heat dissipation prevents LED overheating, a common issue in sealed traditional lighting boards, and extends the overall lifespan of the lighting system. The reduced number of solder joints and connectors in FPCB design also lowers failure risks, enhancing long-term operational reliability in harsh environments.

The Waterproof LED FPCB Lighting Board excels in a wide range of harsh humid environments, delivering targeted value across industrial, commercial, and public infrastructure sectors:

- Marine engineering and offshore facilities: Offshore platforms, ships, and coastal lighthouses operate in high-salt, high-humidity environments that are highly corrosive to traditional lighting. The Waterproof LED FPCB Lighting Board’s corrosion resistance and waterproof performance make it ideal for these applications—including deck lighting, cabin illumination, and navigation signal lighting. Its flexibility also allows it to fit the curved surfaces of ship hulls and offshore equipment.

- Underground corridors and tunnels: Underground spaces such as subway tunnels, utility corridors, and basement parking garages are prone to high humidity, condensation, and water seepage. The Waterproof LED FPCB Lighting Board provides stable lighting in these environments, avoiding short circuits and failures caused by moisture. Its thin, flexible design enables installation along tunnel walls and pipeline exteriors without disrupting traffic or infrastructure operations.

- Smart agricultural greenhouses: Greenhouses require high humidity to support plant growth, creating a challenging environment for lighting systems. The Waterproof LED FPCB Lighting Board can withstand constant moisture and temperature fluctuations, providing reliable supplementary lighting for crops. Its flexibility allows it to be installed along the curved frames of greenhouses or suspended above planting beds, optimizing light distribution while adapting to the greenhouse structure.

- Outdoor landscape and architectural lighting: Outdoor lighting for parks, bridges, and building facades is exposed to rain, snow, and humidity. The Waterproof LED FPCB Lighting Board’s weather resistance ensures year-round reliability, while its flexibility enables creative lighting designs—such as contour lighting for curved bridges and decorative lighting for irregular building facades. It also reduces maintenance costs by minimizing failure rates in harsh weather conditions.

To maximize the performance and lifespan of the Waterproof LED FPCB Lighting Board, follow these scientific implementation strategies:

- Match product selection to environmental conditions: Select the appropriate Waterproof LED FPCB Lighting Board based on the specific environmental characteristics of the application scenario. For highly corrosive marine environments, prioritize products with enhanced anti-corrosion coatings; for underwater applications, choose options with specialized deep-water waterproof designs. Avoid using standard waterproof products in extreme environments beyond their intended scope.

- Optimize installation and fixing methods: Take advantage of the board’s flexibility during installation by conforming it closely to the installation surface. Use waterproof fixing accessories (such as sealed screws and adhesive tapes) to ensure the installation interface remains moisture-proof. Avoid over-bending the board during installation, as this can damage the circuit and compromise waterproof performance.

- Ensure compatible power supply and connection: Use waterproof power supplies and sealed connectors that match the Waterproof LED FPCB Lighting Board. Poorly sealed connections are a common point of moisture penetration, so ensure all electrical connections are properly sealed and insulated. For long-distance installations, use appropriate wiring materials that maintain waterproof performance and reduce voltage drop.

- Implement regular maintenance and inspection: Conduct periodic inspections of the lighting system to check for signs of coating damage, connector loosening, or moisture intrusion. Clean the surface of the lighting board regularly to remove dust, salt deposits, or other contaminants that can affect heat dissipation and waterproof performance. Establish a maintenance schedule based on the harshness of the environment—more frequent inspections for highly corrosive or humid settings.

With advancements in materials science and LED technology, the Waterproof LED FPCB Lighting Board will evolve toward greater performance, intelligence, and sustainability:

- Advanced waterproof material innovation: Future products will use next-generation waterproof materials, such as nanocoatings with self-healing properties, to enhance long-term waterproof reliability. These materials will automatically repair minor coating damage, reducing maintenance needs and extending lifespan in extreme environments.

- Integration with smart sensing technologies: The Waterproof LED FPCB Lighting Board will be integrated with humidity, temperature, and light sensors to enable intelligent adaptive lighting. For example, in greenhouses, the system can automatically adjust light intensity based on humidity and plant growth needs; in tunnels, it can adapt to changes in ambient light and traffic flow.

- Sustainable and energy-efficient design: Manufacturers will focus on developing energy-efficient Waterproof LED FPCB Lighting Boards with higher luminous efficacy. The use of eco-friendly, recyclable materials will also increase, aligning with global sustainability goals. Additionally, integration with renewable energy sources (such as solar power) will make the boards more suitable for remote offshore and outdoor applications.

In conclusion, the Waterproof LED FPCB Lighting Board is a reliable and versatile solution for lighting in harsh humid environments, addressing the limitations of traditional rigid PCB lighting boards. Its integrated waterproof design, flexible adaptability, and efficient heat dissipation make it ideal for marine engineering, underground corridors, greenhouses, and outdoor landscapes. Through scientific product selection, proper installation, and regular maintenance, users can fully leverage its advantages to ensure stable lighting performance and reduce operational costs. As material innovation and smart technology advance, the Waterproof LED FPCB Lighting Board will become even more intelligent and sustainable, solidifying its role as a core component in harsh environment lighting systems. For anyone involved in lighting projects in challenging environments, prioritizing this solution is a strategic choice to enhance reliability and achieve long-term operational efficiency.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB