-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 25. 2025, 11:58:50

With the rapid expansion of high-performance lighting applications—from large-scale sports venues and new energy vehicle lighting to high-end commercial displays and medical surgical lighting—the demand for high brightness LED FPCB (Flexible Printed Circuit Board) has surged. A reliable High Brightness LED FPCB Manufacturer plays a pivotal role in this ecosystem, as it is not only a producer of core components but also a co-innovator that empowers downstream industries to achieve breakthroughs in lighting performance, design flexibility, and energy efficiency. Unlike ordinary LED FPCB manufacturers that focus solely on basic functionality, a professional High Brightness LED FPCB Manufacturer integrates advanced material technology, precision manufacturing processes, and customized solution capabilities to meet the stringent requirements of high-luminance, high-stability lighting scenarios. For enterprises engaged in lighting system design, automotive electronics, and display technology, selecting the right High Brightness LED FPCB Manufacturer is a strategic decision that directly affects product competitiveness and market expansion. This article explores the core capabilities of High Brightness LED FPCB Manufacturers, their empowered application scenarios, key selection criteria, and industry development trends, highlighting their irreplaceable role in the high-performance lighting industry chain.

Ordinary LED FPCB manufacturers face significant limitations in catering to the demands of high brightness lighting applications, failing to meet the core requirements of performance and reliability. Most ordinary manufacturers rely on traditional substrate materials and manufacturing processes, which result in insufficient light reflection efficiency and poor heat dissipation performance of the FPCB. In high brightness lighting systems, this leads to problems such as significant light loss, rapid LED degradation, and shortened service life. For example, in automotive headlight applications that require high luminous flux, FPC boards produced by ordinary manufacturers may experience thermal damage to circuits due to inadequate heat management, affecting driving safety.

Another critical drawback is the lack of customized R&D capabilities and strict quality control systems. High brightness LED FPCB applications often have diverse and personalized requirements, such as adapting to complex curved surfaces in architectural lighting or meeting the miniaturization needs of wearable lighting devices. Ordinary manufacturers typically provide standardized products that cannot be tailored to these specific needs. Additionally, inadequate quality inspection processes—such as the absence of intelligent optical detection (AOI) systems—result in inconsistent product quality, with defects such as circuit short circuits or poor solder joints that can cause entire lighting systems to fail. Professional High Brightness LED FPCB Manufacturers address these gaps through technological innovation, process optimization, and rigorous quality management, becoming reliable partners for downstream high-end applications.

A professional High Brightness LED FPCB Manufacturer distinguishes itself through three core capabilities that support the development of high-performance lighting solutions:

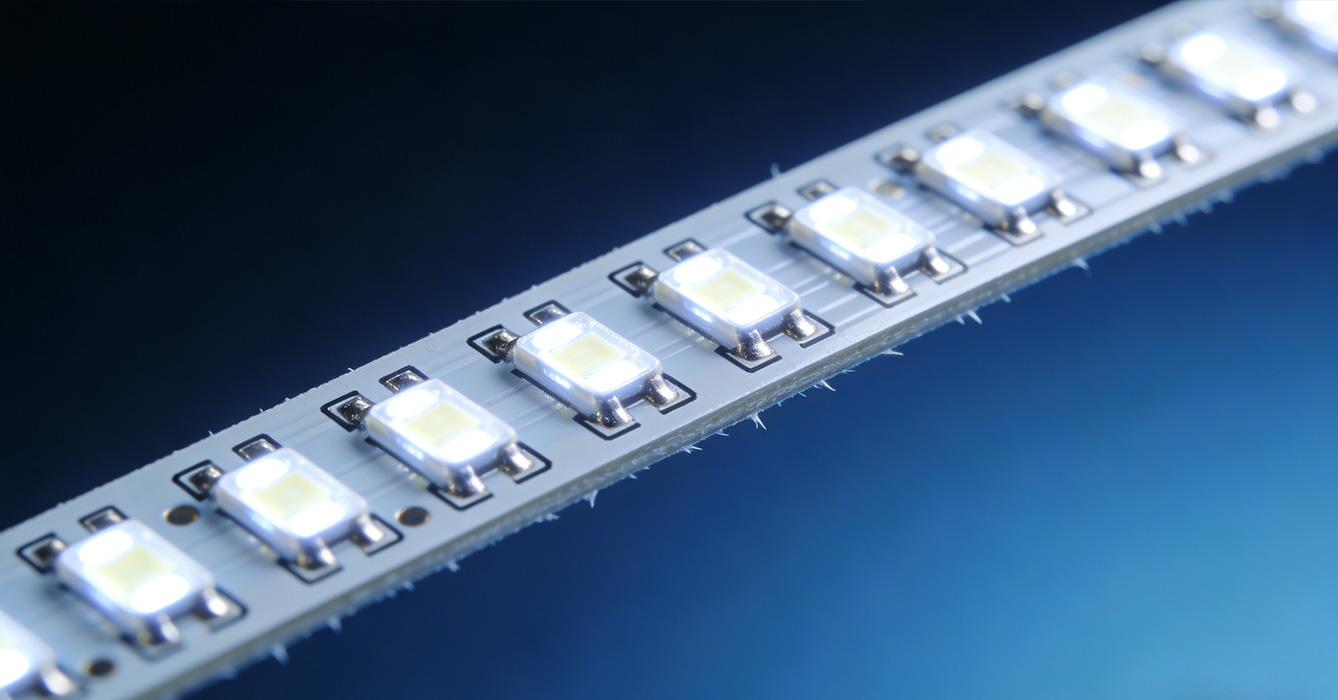

- Advanced material and process innovation capability: Leading High Brightness LED FPCB Manufacturers prioritize R&D investment in high-performance materials, such as adopting high-reflectivity substrate materials and low-resistance copper foils to improve light utilization efficiency and reduce energy loss. They also master precision manufacturing processes, such as fine circuit etching and advanced surface treatment technologies, to ensure the stability and durability of FPCB under high brightness and high-temperature operating conditions. For instance, through optimized circuit layout design, they can effectively reduce heat accumulation, solving the key pain point of heat dissipation in high brightness applications.

- Customized solution development capability: Professional manufacturers focus on understanding the unique needs of different industries and provide one-stop customized solutions from design consultation to mass production. They can develop FPCB products with specific flexibility, thickness, and shape according to the installation environment and performance requirements of downstream products—such as ultra-thin, bendable FPC for automotive interior ambient lighting or high-strength, corrosion-resistant FPC for outdoor large-screen displays. This customized capability enables downstream enterprises to realize innovative product designs that cannot be achieved with standardized products.

- Rigorous quality control and reliability assurance: To ensure the stability of high brightness LED FPCB, professional manufacturers establish comprehensive quality control systems covering the entire production process—from raw material inspection to finished product testing. They adopt advanced testing equipment such as AOI systems and thermal performance test benches to detect potential defects in advance and ensure that each batch of products meets international quality standards. Additionally, they conduct long-term reliability tests (such as high-temperature and high-humidity aging tests) to verify the service life and performance stability of FPCB in extreme operating environments.

Professional High Brightness LED FPCB Manufacturers empower a wide range of high-performance lighting applications, driving innovation across automotive, commercial, medical, and sports industries:

- New energy vehicle lighting systems: The automotive industry's demand for high-brightness, energy-efficient lighting (such as LED headlights, daytime running lights, and interior ambient lighting) is growing rapidly. High Brightness LED FPCB Manufacturers provide lightweight, flexible FPCB solutions that fit the complex curved surfaces of automotive lighting fixtures. These solutions offer excellent heat dissipation and high luminous efficiency, supporting the development of intelligent automotive lighting systems that enhance driving safety and comfort.

- Large-scale sports venues and stadiums: Sports venues require uniform, high-brightness lighting to meet the needs of competitions and live broadcasts. High Brightness LED FPCB Manufacturers supply high-performance FPCB for stadium lighting systems, ensuring stable light output and uniform illumination. The flexibility of FPCB also enables creative lighting designs for stadium contours, enhancing the visual experience of audiences and athletes.

- High-end commercial displays and signage: Commercial displays (such as transparent LED screens and curved billboards) demand high brightness to ensure clear visibility under strong outdoor light. Professional manufacturers develop FPCB with high light transmittance and high brightness compatibility, enabling displays to maintain vivid colors and clear images even in direct sunlight. Their customized capabilities also support the production of large-size, irregular-shaped display modules.

- Medical and surgical lighting: Medical lighting requires high brightness, uniform light distribution, and stable performance to ensure accurate diagnosis and surgical operations. High Brightness LED FPCB Manufacturers provide FPCB solutions with strict quality control and high reliability, supporting the development of medical lighting devices that meet the stringent hygiene and performance standards of the healthcare industry. The compact design of FPCB also helps miniaturize medical lighting equipment, improving its usability in operating rooms.

Enterprises should consider the following key factors when selecting a High Brightness LED FPCB Manufacturer to ensure optimal cooperation results:

- Technological R&D strength: Evaluate the manufacturer's R&D team, patent layout, and technological innovation achievements in high brightness LED FPCB. Prioritize manufacturers that have long-term experience in the industry and can keep up with the latest material and process trends (such as integration with Mini/Micro LED technology).

- Customization capability and service level: Choose manufacturers that can provide personalized solutions and offer comprehensive services such as design support, sample testing, and technical consultation. A responsive after-sales service team is also essential to address any issues that may arise during product application.

- Quality control system and certification: Verify that the manufacturer has established a complete quality control system and holds relevant international certifications (such as RoHS, REACH) to ensure that products meet environmental and quality standards. Inquire about their testing equipment and reliability test processes to assess product stability.

- Production capacity and supply chain stability: Ensure that the manufacturer has sufficient production capacity to meet large-order requirements and maintain stable supply. A sound supply chain system for raw materials is also critical to avoid production delays caused by material shortages.

Driven by technological advancements and market demand, High Brightness LED FPCB Manufacturers will develop toward intelligence, integration, and sustainability:

- Integration with Mini/Micro LED technology: As Mini/Micro LED technology matures, manufacturers will focus on developing high-precision, high-density FPCB solutions to support the production of ultra-high-definition displays and high-performance lighting products. This integration will require more advanced manufacturing processes and stricter quality control.

- Intelligent manufacturing and digital transformation: Manufacturers will adopt automated production lines, AI-driven quality inspection systems, and digital management platforms to improve production efficiency, reduce costs, and enhance product consistency. Intelligent manufacturing will also enable faster response to customized orders.

- Green and sustainable development: In response to global environmental regulations, manufacturers will increase the use of eco-friendly materials and adopt energy-saving production processes. The development of recyclable FPCB and lead-free manufacturing technologies will become key trends, aligning with the industry's sustainability goals.

In conclusion, a professional High Brightness LED FPCB Manufacturer is a core partner for enterprises pursuing high-performance lighting solutions, addressing the limitations of ordinary manufacturers in technology, customization, and quality. Through advanced material innovation, customized services, and rigorous quality control, they empower diverse applications across automotive, sports, commercial, and medical industries. By selecting manufacturers based on R&D strength, customization capability, quality control, and supply chain stability, enterprises can enhance their product competitiveness and seize market opportunities. As technology evolves, High Brightness LED FPCB Manufacturers will continue to drive innovation in the lighting industry, playing an increasingly important role in the development of intelligent, high-efficiency, and sustainable lighting systems. For any enterprise engaged in high-end lighting innovation, collaborating with a reliable High Brightness LED FPCB Manufacturer is a strategic investment in long-term success.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB