-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

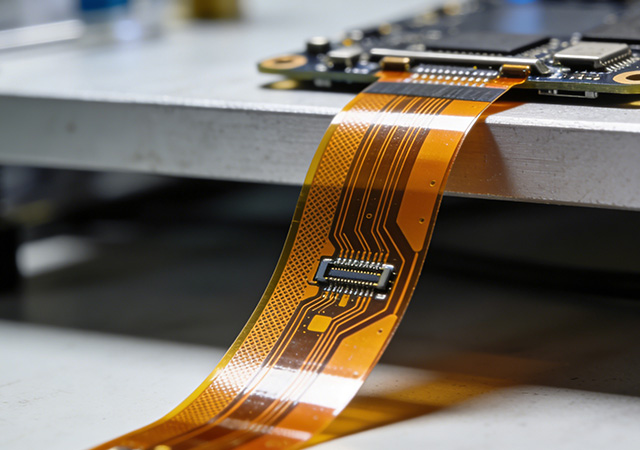

As smartphone design evolves beyond traditional rigid forms toward foldable, rollable, and slider configurations, a Flexible Smartphone FPC Manufacturer has become a core enabler of this morphological innovation. Specializing in flexible printed circuits (FPCs) engineered for the dynamic operating demands of modern smartphones, these manufacturers go beyond basic flexibility—they tailor solutions to balance mechanical adaptability, signal stability, and long-term durability. Unlike generic FPC manufacturers, a Flexible Smartphone FPC Manufacturer deeply understands the unique stressors of flexible mobile devices (e.g., repeated folding, dynamic component movement) and the industry’s pursuit of versatile user experiences. For smartphone brands aiming to differentiate in the competitive market through innovative form factors, partnering with a professional Flexible Smartphone FPC Manufacturer is a pivotal step in turning bold design concepts into reliable, market-ready products.

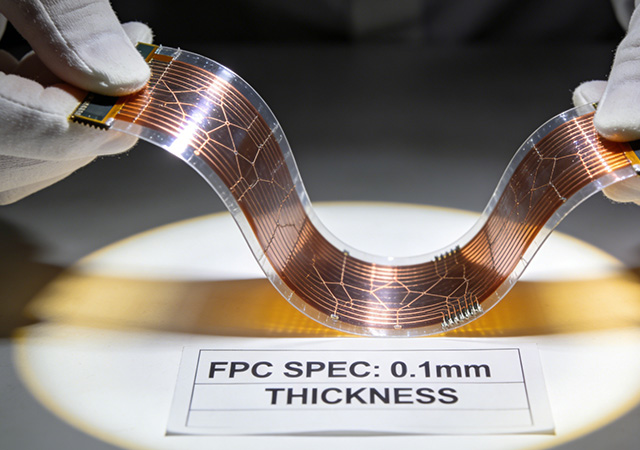

In the fiercely competitive smartphone market, where slim form factors, multi-functional integration, and user experience innovation are core battlegrounds, an Ultra-Thin Smartphone FPC Supplier has evolved from a component provider to a critical strategic collaborator. Specializing in ultra-thin flexible printed circuits (FPCs) tailored for the unique demands of modern smartphones, these suppliers go beyond basic manufacturing—they co-innovate with smartphone brands to solve design bottlenecks, optimize performance, and accelerate product launch cycles. Unlike general FPC suppliers, an Ultra-Thin Smartphone FPC Supplier deeply understands the smartphone industry’s fast iteration rhythm and strict quality standards, focusing on the synergy between ultra-thin design, functional integration, and long-term reliability. For brands striving to lead in the premium and foldable smartphone segments, partnering with such a supplier is a decisive factor in translating innovative concepts into ma

In the era of intelligent and interconnected flexible electronics, a professional FPC manufacturer is no longer a mere component producer but a comprehensive technology partner that drives innovation through integrated solutions and full-lifecycle support. Specializing in flexible printed circuits (FPCs)—the core of compact, dynamic, and high-performance electronic devices—top FPC manufacturers distinguish themselves by integrating diverse advanced technologies (such as gold bonding, blind/buried vias, and high-density assembly) and providing end-to-end services from initial design to post-production maintenance. Unlike generic manufacturers focused solely on production, these FPC manufacturers deeply understand the cross-industry technical demands, enabling them to deliver tailored solutions that balance performance, cost, and reliability. For enterprises developing cutting-edge products in 5G, automotive, and medical fields, partnering with such an FPC manufacturer is critical to tra

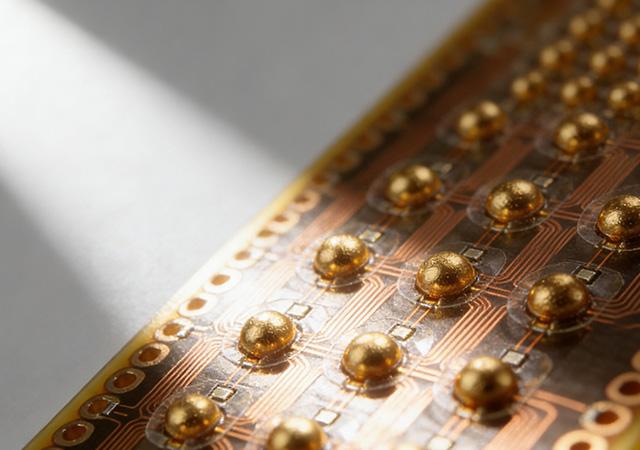

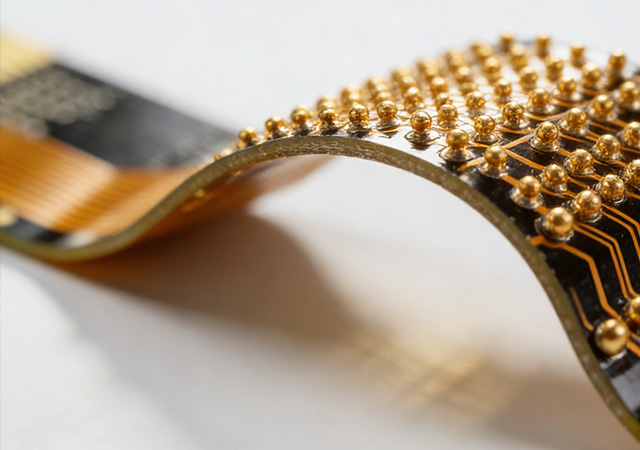

As flexible electronics evolve toward miniaturization, high integration, and dynamic operation, FPC gold ball bonding has emerged as a pivotal interconnection technology that bridges the gap between component density and operational reliability. This specialized process integrates gold ball bonding—renowned for its precision and conductivity—with flexible printed circuits (FPCs), enabling robust electrical connections between FPC substrates and ultra-small components. Unlike traditional soldering or other wire bonding methods, FPC gold ball bonding leverages gold’s inherent ductility, corrosion resistance, and low electrical resistance to thrive in applications requiring repeated bending, extreme miniaturization, or high-frequency signal transmission. For manufacturers developing next-generation flexible devices—from wearable sensors to automotive dynamic components—FPC gold ball bonding has become an indispensable technology to unlock design flexibility and performance potential.

In mission-critical electronic systems where even minor failures can lead to catastrophic consequences—such as medical implants, aerospace avionics, and automotive safety systems—High Reliability Gold Bonding FPC has become an indispensable core component. Unlike standard gold bonding FPCs that prioritize basic connectivity, High Reliability Gold Bonding FPC integrates advanced gold bonding technologies with rigorous design and manufacturing controls to deliver exceptional stability, durability, and performance under extreme operating conditions. Leveraging gold’s inherent advantages of excellent conductivity, corrosion resistance, and ductility, this specialized FPC ensures uninterrupted operation in harsh environments ranging from extreme temperatures to chemical exposure. For manufacturers developing high-end, life-or-mission-critical products, adopting High Reliability Gold Bonding FPC is a strategic decision to safeguard product integrity and brand credibility.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB