-

- PCB TYPE

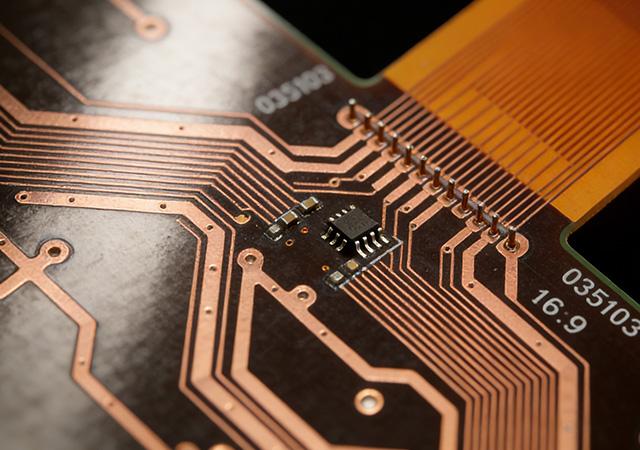

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

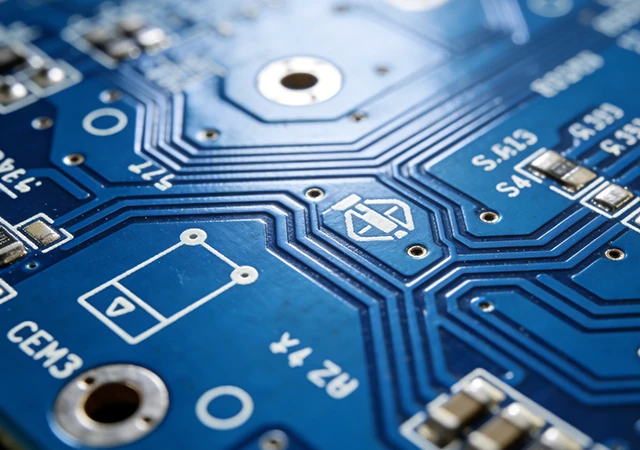

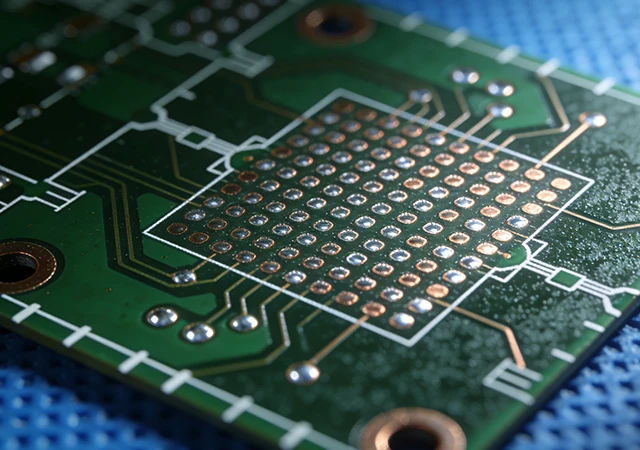

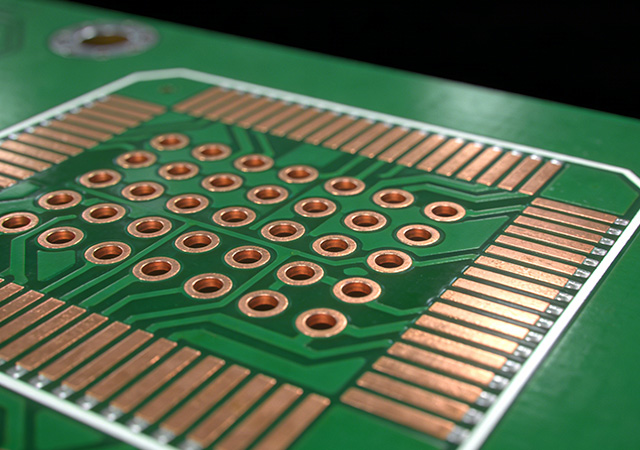

As industrial electronics continue to evolve toward higher reliability and tighter cost control, selecting the right printed circuit board material has become a strategic decision for manufacturers and OEMs. From industrial control systems to power management modules, the substrate material directly impacts performance, manufacturability, and total production cost. Among various PCB materials, CEM3 PCB stands out as a practical and cost-effective solution for a wide range of industrial electronics applications.

ApolloPCB is a leading FR4 PCB manufacturer since 2002. Specializing in High Tg FR4 PCB, multi-layer rigid boards, and complex stackups. ISO & UL certified. Get a 12h quote!

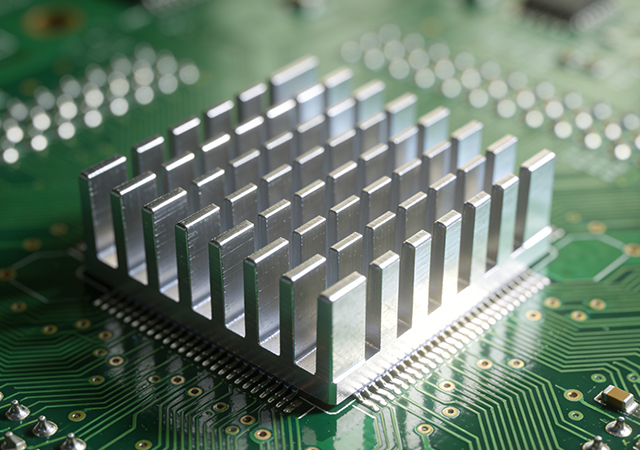

Leading aluminum PCB manufacturer since 2002. We provide single-layer & multi-layer aluminum PCB boards with thermal conductivity up to 9.0 W/m.K. Get a free DFM quote!

Explore what CEM3 PCB is, its Composite Epoxy Material-3 properties, performance advantages, comparing with FR-4, manufacturing insights, key applications, and how to choose a reliable CEM-3 PCB manufacturer for your project.

From FR4 PCB prototypes to stable volume production—clear FR4 PCB material specification, DFM support, and consistent quality. Request a fast quote.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB