-

- PCB TYPE

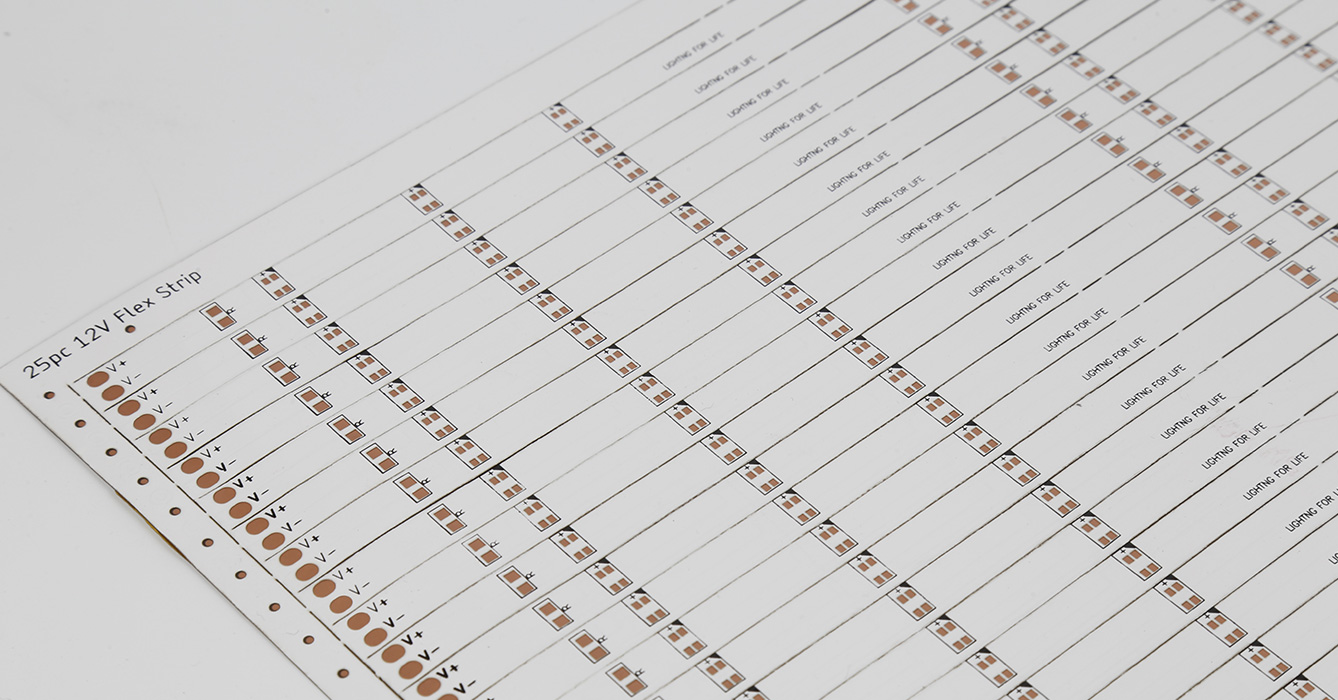

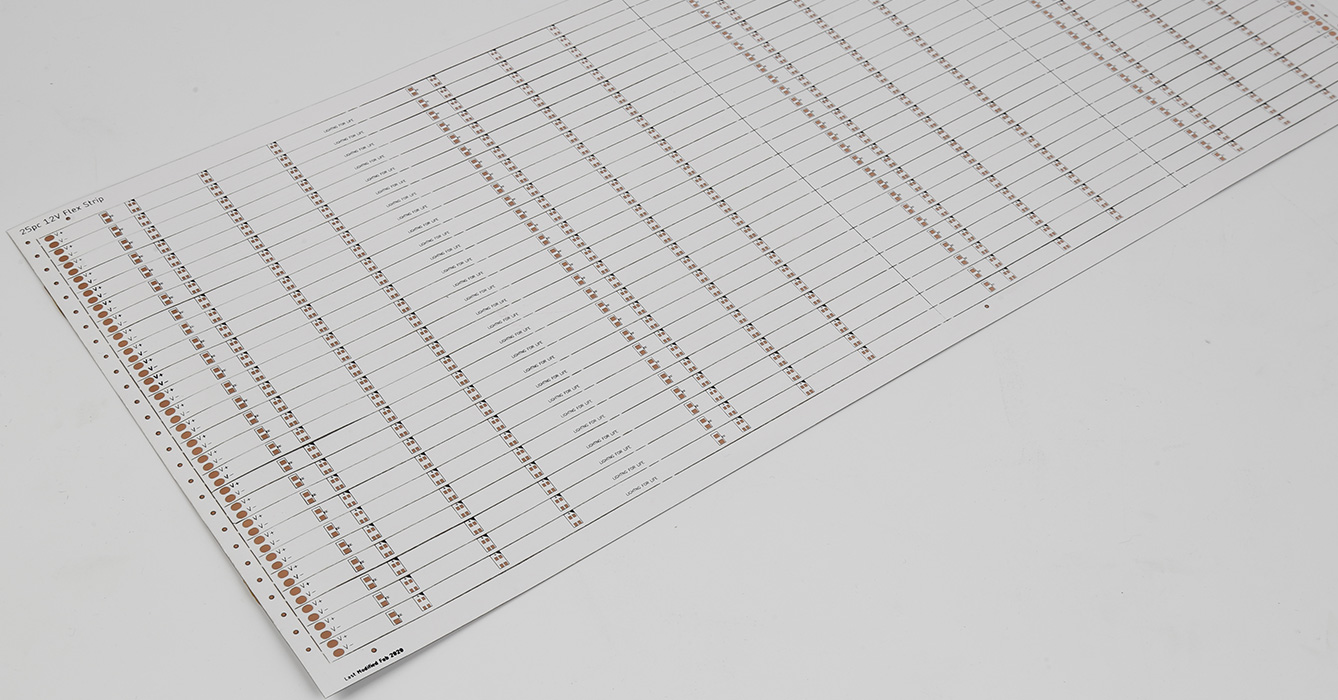

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 19. 2025, 13:26:37

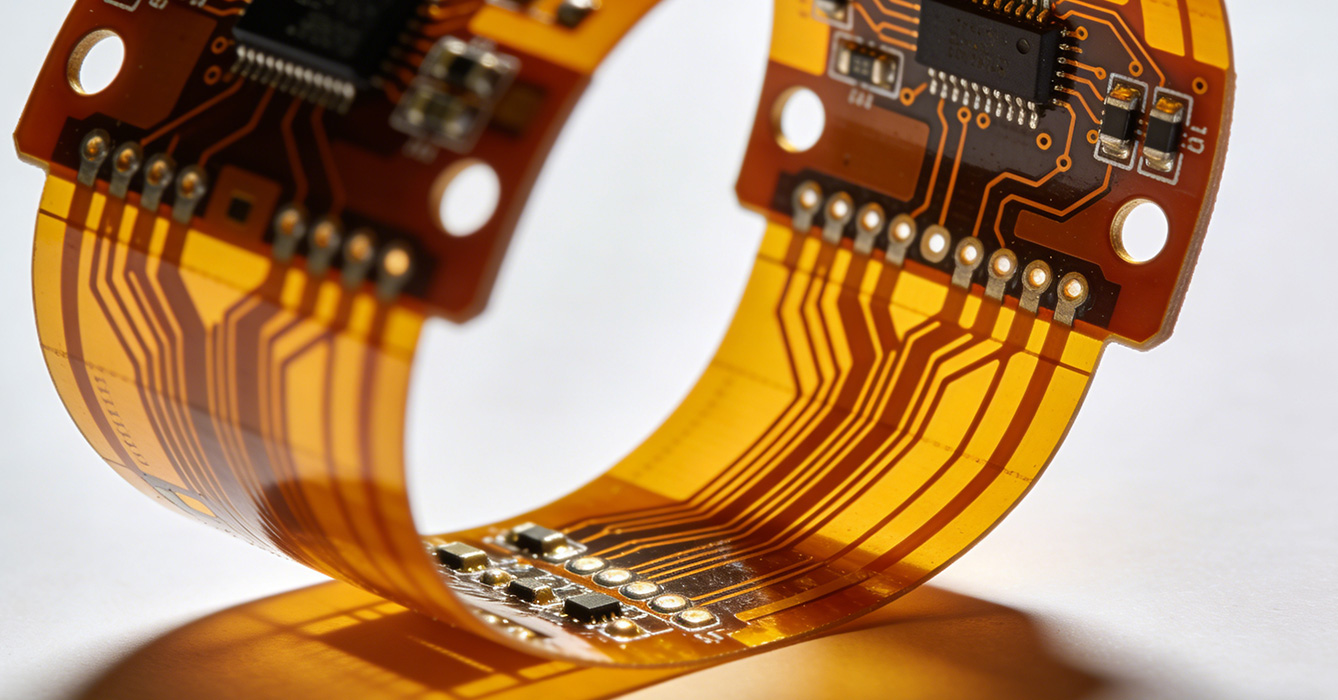

In the era of rapid technological innovation, electronic devices are becoming increasingly specialized—demanding components that adapt to unique designs, environments, and functional requirements. Flexible printed circuit boards (Flex PCBs) have emerged as a cornerstone of this evolution, offering versatility, compactness, and durability that rigid PCBs cannot match. For businesses seeking to turn their unique concepts into reality, partnering with a reputable Custom Flexible PCB Manufacturer is a strategic choice that bridges design ambition with practical functionality. These specialized manufacturers prioritize customization, crafting Flex PCBs tailored to the specific needs of industries ranging from consumer tech to medical devices and beyond.

Generic, off-the-shelf Flex PCBs may serve basic purposes, but they often fail to meet the nuanced demands of modern electronic design. Every device has distinct spatial constraints, performance goals, and environmental conditions—whether it’s a wearable health monitor requiring ultra-thin flexibility, an industrial sensor needing resistance to extreme temperatures, or a aerospace component demanding lightweight reliability. A Custom Flexible PCB Manufacturer addresses these gaps by working closely with clients to develop solutions that align with their exact specifications. Unlike mass-produced alternatives, custom Flex PCBs eliminate unnecessary features, optimize form factors, and integrate design elements that enhance overall device performance, making them indispensable for innovative products.

A top-tier Custom Flexible PCB Manufacturer excels at adapting to the unique needs of diverse sectors, proving that customization is not a one-size-fits-all process but a tailored approach to each industry’s challenges. In consumer electronics, custom Flex PCBs enable the sleek, foldable designs of smartphones and tablets, as well as the compactness of wireless earbuds and smartwatches. The medical industry relies on custom solutions for devices like implantable monitors and portable diagnostic tools, where biocompatibility, miniaturization, and precise signal transmission are non-negotiable. Automotive manufacturers turn to Custom Flexible PCB Manufacturers for components that fit into tight engine bays or curved interior panels, supporting advanced driver-assistance systems (ADAS) and electric vehicle technology. Even in industrial settings, custom Flex PCBs withstand harsh conditions, powering sensors and control systems that operate in dusty, high-vibration environments. Across all these fields, the ability to customize ensures that Flex PCBs do not just fit into devices—they elevate their capabilities.

The success of a custom Flex PCB project hinges on collaboration between the manufacturer and the client. A trusted Custom Flexible PCB Manufacturer does more than execute designs; they act as technical partners, bringing expertise to every stage of the process. From the initial consultation, their engineering teams work to understand the client’s goals, address design challenges, and offer insights to optimize performance and manufacturability. Whether it’s suggesting material modifications to improve flexibility, adjusting layouts to reduce signal interference, or refining designs to meet regulatory standards, this collaborative approach ensures that the final product not only meets expectations but exceeds them. Prototyping is a key part of this journey, allowing clients to test and refine custom Flex PCBs before full-scale production, minimizing risks and ensuring alignment with their vision.

Not all Custom Flexible PCB Manufacturers are created equal—several key traits distinguish the industry leaders. First and foremost is a commitment to quality: reputable manufacturers implement rigorous quality control measures throughout the customization and production process, ensuring that each custom Flex PCB adheres to international standards and client specifications. They also invest in advanced technology and skilled engineering teams, enabling them to tackle complex designs and stay ahead of industry trends. Flexibility in production is another critical factor, as leading manufacturers can accommodate both small-batch prototypes and larger production runs without compromising on customization or lead times. Finally, exceptional customer support—from initial design discussions to post-delivery assistance—fosters long-term partnerships, as clients trust that their unique needs will be prioritized at every step.

As electronic devices continue to evolve in complexity and specialization, the demand for tailored solutions will only grow. A Custom Flexible PCB Manufacturer plays a pivotal role in this ecosystem, turning innovative ideas into functional, reliable components that drive progress across industries. By prioritizing customization, collaboration, and quality, these manufacturers empower businesses to differentiate their products, overcome design challenges, and succeed in a competitive global market. Whether you’re developing a groundbreaking wearable device, a life-saving medical tool, or a next-generation automotive component, partnering with the right Custom Flexible PCB Manufacturer is the key to unlocking the full potential of your design—proving that when it comes to electronic components, one size never fits all.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB