-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 19. 2025, 13:24:45

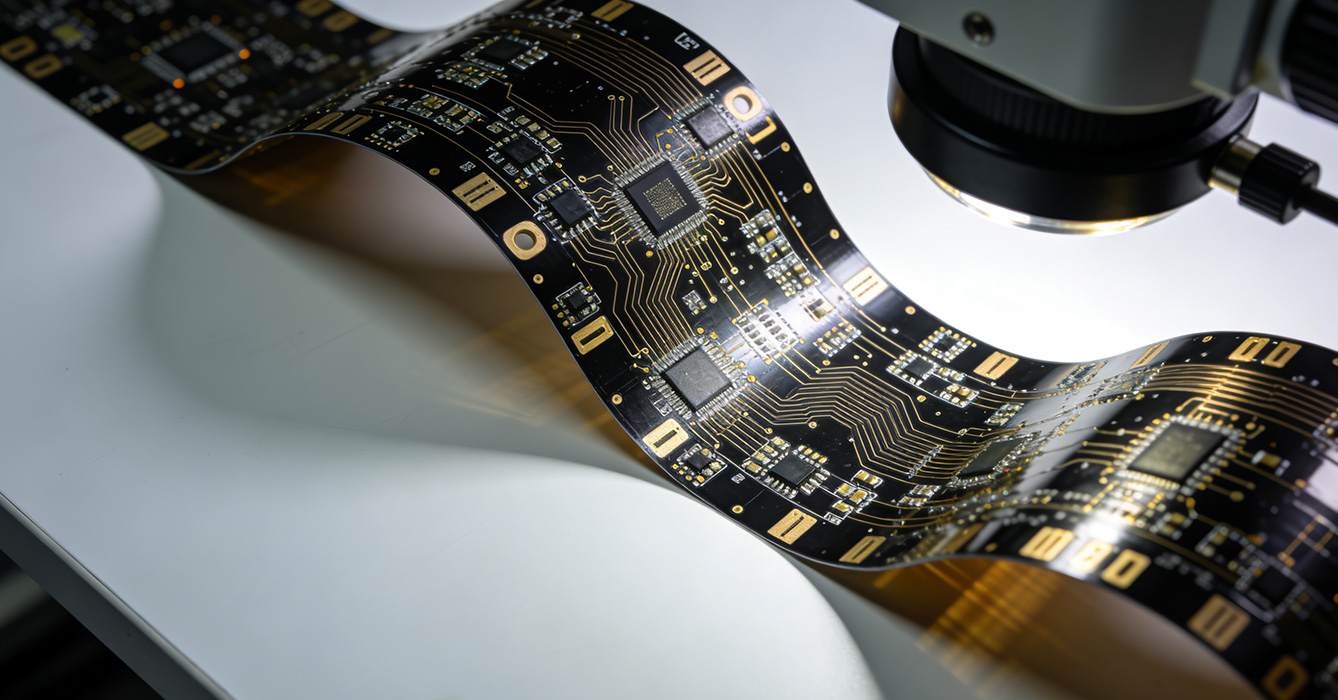

In today’s fast-paced electronic landscape, the demand for flexible printed circuit boards (Flex PCBs) continues to surge—driven by the need for compact, lightweight, and durable components in devices ranging from consumer electronics to industrial machinery. For businesses scaling their production lines, partnering with a reliable High Volume Flex PCB Manufacturer is no longer an option but a strategic necessity. These specialized manufacturers play a pivotal role in translating innovative designs into mass-produced, high-quality Flex PCBs that meet the rigorous standards of global industries.

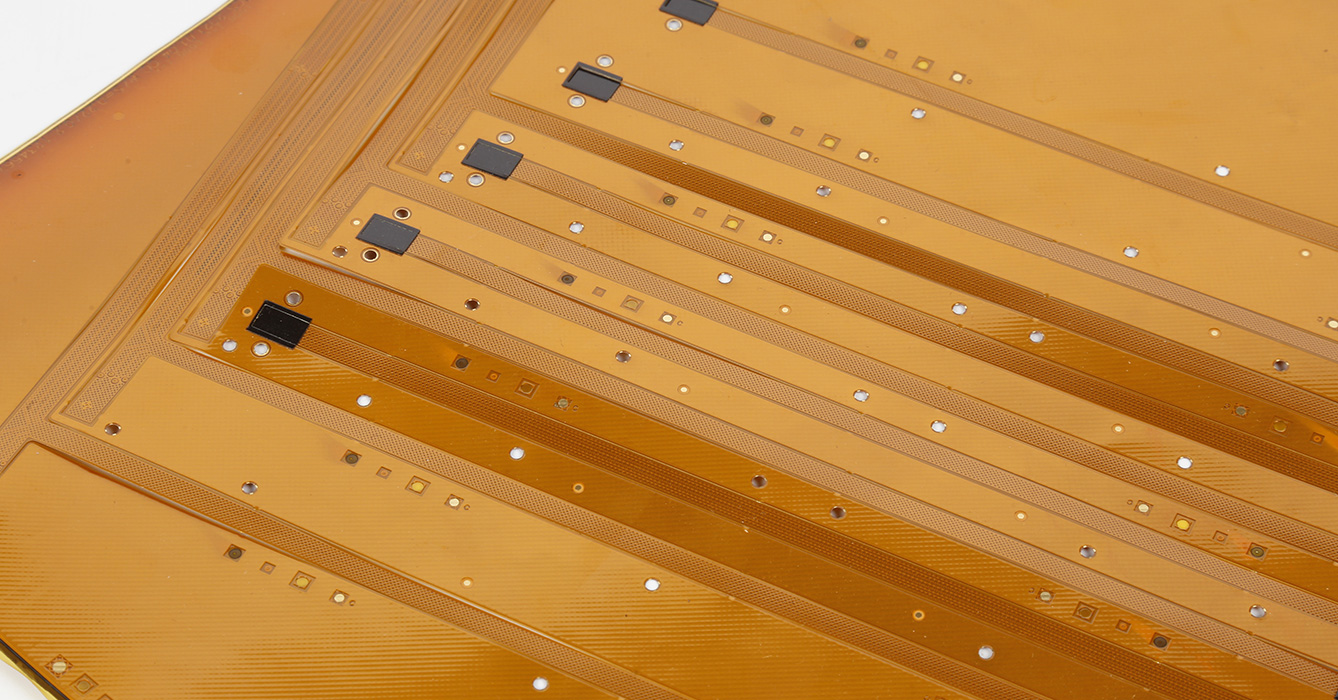

The rise of smart devices, wearable technology, automotive electronics, and medical equipment has amplified the need for Flex PCBs that can keep up with high-volume production without compromising performance. Unlike traditional rigid PCBs, Flex PCBs offer unparalleled flexibility, allowing them to fit into tight spaces and adapt to complex device geometries. However, producing these boards in large quantities requires specialized expertise, advanced manufacturing processes, and a commitment to consistency—all hallmarks of a top-tier High Volume Flex PCB Manufacturer.

One of the key reasons businesses prioritize partnering with a dedicated High Volume Flex PCB Manufacturer is the ability to achieve economies of scale. These manufacturers leverage state-of-the-art production facilities, automated assembly lines, and optimized supply chains to produce Flex PCBs in bulk at competitive costs. By streamlining processes from design validation to final assembly, they eliminate inefficiencies that often plague small-scale production, ensuring timely delivery even for the most demanding order volumes. This scalability is critical for businesses looking to meet market demand, expand their customer base, or launch new products on a global scale.

Quality control is another non-negotiable aspect of high-volume Flex PCB production. A reputable High Volume Flex PCB Manufacturer implements rigorous testing protocols at every stage of the manufacturing process. From material inspection to electrical performance testing, each batch of Flex PCBs undergoes strict quality checks to ensure compliance with international standards. This attention to detail minimizes the risk of defects, reduces downtime for customers, and upholds the reliability of end products. For industries like healthcare and automotive, where product failure can have serious consequences, partnering with a manufacturer that prioritizes quality is essential.

Beyond production capacity and quality, a leading High Volume Flex PCB Manufacturer offers valuable technical support and collaboration. These manufacturers work closely with clients to optimize designs for high-volume production, providing insights on material selection, layout efficiency, and cost-saving opportunities. Their engineering teams have the expertise to address complex design challenges, ensuring that Flex PCBs not only meet technical specifications but also align with production timelines and budget constraints. This collaborative approach fosters long-term partnerships, as clients benefit from a trusted advisor who understands their unique needs and industry requirements.

The applications of high-volume Flex PCBs are vast and diverse. In the consumer electronics sector, they power smartphones, tablets, and wearable devices, enabling sleek designs and reliable performance. In automotive manufacturing, Flex PCBs are used in advanced driver-assistance systems (ADAS), infotainment systems, and electric vehicle components, where durability and space efficiency are paramount. The medical industry relies on high-volume Flex PCBs for diagnostic equipment, wearable health monitors, and implantable devices, where precision and biocompatibility are critical. Across all these sectors, a High Volume Flex PCB Manufacturer serves as the backbone of innovation, enabling businesses to bring cutting-edge products to market efficiently.

In a global market defined by rapid technological advancements and increasing competition, choosing the right High Volume Flex PCB Manufacturer can give businesses a significant edge. These manufacturers combine scalability, quality, and technical expertise to deliver Flex PCBs that meet the demands of high-volume production while supporting innovation. Whether a business is launching a new product line, expanding into new markets, or seeking to optimize its supply chain, partnering with a specialized High Volume Flex PCB Manufacturer is a strategic investment that pays dividends in reliability, cost savings, and market success.

As the demand for flexible electronics continues to grow, the role of High Volume Flex PCB Manufacturers will only become more critical. By staying ahead of industry trends, investing in advanced technology, and prioritizing customer collaboration, these manufacturers are poised to drive the next wave of innovation in high-scale electronic production. For businesses looking to thrive in a dynamic market, aligning with a trusted High Volume Flex PCB Manufacturer is the key to unlocking scalability, quality, and long-term growth.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB