-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jul 07. 2025, 10:57:53

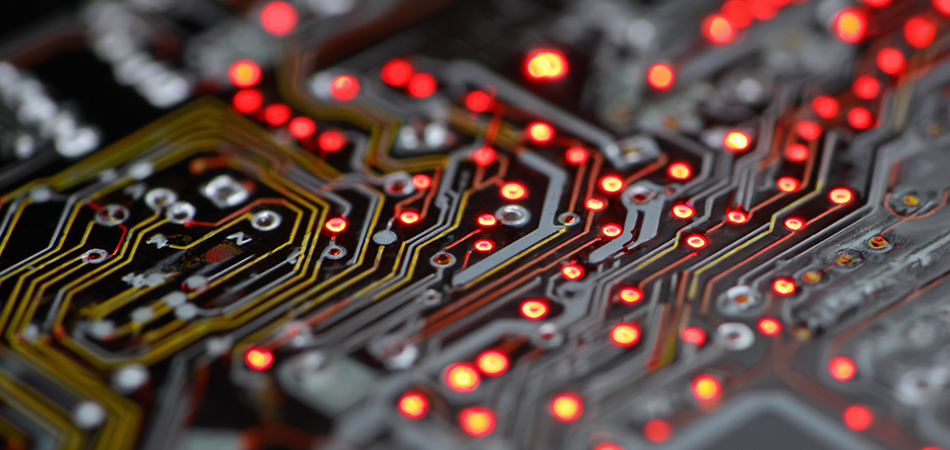

In the ever - evolving landscape of modern lighting technology, LED circuits boards have emerged as the linchpin for efficient and innovative illumination solutions. These boards serve as the foundation for powering light - emitting diodes (LEDs), enabling them to deliver superior performance, energy efficiency, and extended lifespan. From residential and commercial settings to specialized applications in automotive, aerospace, and healthcare, LED circuits boards have revolutionized the way we light our world. This article delves deep into the world of LED circuits boards, exploring their material composition, design principles, manufacturing processes, quality assurance measures, diverse applications, and emerging market trends.

Material Composition of LED Circuits Boards

Substrate Materials

The choice of substrate material in LED circuits boards is a critical decision that significantly impacts the overall performance and reliability of the lighting system. Different substrate materials offer distinct advantages, depending on the specific requirements of the application.

Aluminum substrates have gained widespread popularity due to their excellent thermal conductivity. LEDs generate a significant amount of heat during operation, and efficient heat dissipation is crucial for maintaining their performance and lifespan. Aluminum substrates effectively transfer heat away from the LEDs, preventing overheating and ensuring stable operation. Additionally, aluminum offers good mechanical strength and formability, making it suitable for a variety of lighting fixtures.

FR4, a fiberglass - reinforced epoxy laminate, is another commonly used substrate material. It provides good electrical insulation and mechanical stability, making it suitable for applications where cost - effectiveness and standard performance are required. However, FR4 has relatively lower thermal conductivity compared to aluminum, which may limit its use in high - power LED applications where efficient heat dissipation is essential.

Ceramic substrates, such as aluminum nitride (AlN) and aluminum oxide (Al₂O₃), offer superior thermal conductivity and electrical insulation properties. They are ideal for high - power, high - temperature applications where reliable performance and long - term durability are critical. Ceramic substrates can withstand extreme operating conditions, making them suitable for applications in automotive, aerospace, and industrial lighting.

Dielectric Layers

The dielectric layer in LED circuits boards serves as an electrical insulator between the conductive traces and the substrate, while also facilitating heat transfer. The selection of the dielectric material is crucial for optimizing the electrical and thermal performance of the board.

Polyimide - based dielectrics are known for their high - temperature resistance and excellent electrical insulation properties. They can withstand elevated temperatures without significant degradation, making them suitable for high - power LED applications. Polyimide dielectrics also offer low dielectric loss, which helps to minimize signal attenuation and improve the overall efficiency of the circuit.

Ceramic - filled epoxies are another popular choice for dielectric layers. These materials combine the advantages of epoxy resins, such as good adhesion and processability, with the high thermal conductivity of ceramic fillers. Ceramic - filled epoxies provide a cost - effective solution for improving the thermal performance of LED circuits boards, making them suitable for a wide range of applications.

Conductive Traces

Copper is the most commonly used material for the conductive traces in LED circuits boards due to its low electrical resistance and excellent conductivity. The thickness and width of the copper traces are carefully designed to ensure efficient power delivery to the LEDs while minimizing power losses and heat generation.

In high - power LED applications, thicker copper traces are often used to handle the increased current flow. This helps to reduce voltage drops and ensure that each LED receives the appropriate amount of power. Surface treatments, such as electroless nickel immersion gold (ENIG), electroless nickel electroless palladium immersion gold (ENEPIG), and organic solderability preservatives (OSP), are applied to the copper traces to enhance their corrosion resistance, solderability, and long - term reliability.

Design Principles of LED Circuits Boards

Thermal Management Design

Thermal management is one of the most critical aspects of LED circuits board design. Effective heat dissipation is essential for maintaining the performance and lifespan of the LEDs, as well as ensuring the overall reliability of the lighting system.

Thermal vias play a crucial role in thermal management by providing a direct pathway for heat to transfer from the LEDs to the substrate. These vias are strategically placed to maximize heat dissipation and minimize thermal resistance. The size, number, and distribution of thermal vias are carefully optimized based on the power requirements and thermal characteristics of the LEDs.

In addition to thermal vias, heat sinks and heat spreaders are often used to enhance heat dissipation. Heat sinks increase the surface area available for heat transfer, while heat spreaders help to evenly distribute the heat across the substrate. The design of the heat sink and heat spreader is optimized to ensure efficient heat transfer and minimize the temperature gradient across the LED array.

Electrical Design

The electrical design of LED circuits boards focuses on ensuring stable and efficient power supply to the LEDs. This includes designing the appropriate current - limiting circuits, voltage regulators, and driver circuits to regulate the current and voltage supplied to the LEDs.

In multi - LED arrays, careful consideration must be given to the electrical configuration of the LEDs, whether in series, parallel, or a combination of both. Series - connected LEDs require a higher voltage but lower current, while parallel - connected LEDs require a lower voltage but higher current. The choice of electrical configuration depends on the specific requirements of the application, such as the desired brightness, color temperature, and power consumption.

Electromagnetic compatibility (EMC) is also an important consideration in the electrical design of LED circuits boards. LED drivers can generate electromagnetic interference (EMI), which may disrupt other electronic devices in the vicinity. Therefore, proper shielding, filtering, and layout techniques are employed to minimize EMI and ensure compliance with EMC standards.

Mechanical Design

The mechanical design of LED circuits boards takes into account factors such as the physical dimensions of the board, the mounting method, and the mechanical stresses it may encounter during operation. The size and shape of the board are determined by the requirements of the lighting fixture and the number and arrangement of the LEDs.

Mounting holes and attachment mechanisms are incorporated into the board design to securely fasten the board to the lighting fixture. The choice of mounting method, such as screw - mounting, snap - fitting, or adhesive bonding, depends on the design of the fixture and the environmental conditions in which the board will operate.

In outdoor or harsh - environment applications, the mechanical design of the board must also consider factors such as resistance to vibration, shock, and corrosion. Reinforcement features, such as stiffeners or protective enclosures, may be added to enhance the mechanical durability of the board.

Optical Design

Optical design is closely intertwined with the electrical and mechanical design of LED circuits boards. The placement and orientation of the LEDs on the board directly affect the light distribution pattern of the lighting fixture. Therefore, careful consideration must be given to the optical design to ensure that the desired light output characteristics are achieved.

Optical components, such as lenses, reflectors, and diffusers, are often used in conjunction with LED circuits boards to control the light distribution and enhance the performance of the lighting system. The design of these optical components is optimized to maximize the light extraction efficiency and minimize light losses.

Manufacturing Processes of LED Circuits Boards

Circuit Board Fabrication

The fabrication of LED circuits boards involves a series of processes, including drilling, plating, lamination, and etching. These processes are carefully controlled to ensure the precision and quality of the board.

Drilling is the first step in the fabrication process, which creates holes for vias, component mounting, and other purposes. Mechanical drilling and laser drilling are the two commonly used methods for drilling holes in circuit boards. Mechanical drilling is a cost - effective method for creating larger holes, while laser drilling offers higher precision and is suitable for creating smaller holes.

Plating is used to deposit a layer of copper on the drilled holes and the surface of the board to ensure electrical conductivity. Electroless plating and electrolytic plating are the two main types of plating processes used in circuit board fabrication. Electroless plating is used to deposit a thin layer of copper on non - conductive surfaces, while electrolytic plating is used to build up the copper layer to the desired thickness.

Lamination is the process of bonding the different layers of the circuit board together, including the substrate, dielectric layer, and copper traces. High - pressure lamination and vacuum lamination are the two commonly used methods for lamination. High - pressure lamination uses heat and pressure to bond the layers together, while vacuum lamination uses a vacuum to remove air bubbles and ensure a uniform bond.

Etching is the process of removing the unwanted copper from the surface of the board to create the desired circuit pattern. Chemical etching and dry etching are the two main types of etching processes used in circuit board fabrication. Chemical etching uses chemicals to dissolve the unwanted copper, while dry etching uses plasma or ion beams to remove the copper.

Component Mounting

After the circuit board is fabricated, the next step is to mount the components onto the board. Surface - mount technology (SMT) is the most commonly used method for mounting components on LED circuits boards. SMT involves placing the components onto the surface of the board using automated pick - and - place machines and then soldering them in place using reflow soldering or wave soldering.

Reflow soldering is the most widely used soldering method for SMT components. It involves heating the board in a reflow oven, which melts the solder paste and creates a strong electrical and mechanical connection between the components and the board. Wave soldering is another soldering method that is commonly used for through - hole components. It involves passing the board over a wave of molten solder, which solders the components in place.

Testing and Quality Assurance

Once the components are mounted on the board, the next step is to test the board to ensure that it meets the required specifications. Electrical testing, optical testing, and thermal testing are the three main types of tests that are performed on LED circuits boards.

Electrical testing involves testing the electrical properties of the board, such as the resistance, capacitance, and impedance of the components and the traces. Optical testing involves testing the light output characteristics of the board, such as the luminous intensity, color temperature, and color rendering index of the LEDs. Thermal testing involves testing the thermal performance of the board, such as the temperature distribution and the heat dissipation efficiency of the LEDs and the substrate.

In addition to these tests, quality assurance measures are also implemented throughout the manufacturing process to ensure the quality and reliability of the boards. These measures include incoming material inspection, in - process inspection, and final inspection.

Applications of LED Circuits Boards

Residential Lighting

LED circuits boards are widely used in residential lighting applications, such as ceiling lights, wall sconces, table lamps, and recessed downlights. The energy - efficiency and long lifespan of LEDs make them an attractive choice for homeowners, as they can significantly reduce energy consumption and maintenance costs.

LED circuits boards also offer a high degree of design flexibility, allowing for the creation of customized lighting solutions that can enhance the ambiance and functionality of any living space. With the ability to control the color, brightness, and intensity of the light, LED circuits boards can be used to create a variety of lighting effects, from warm and cozy to bright and vibrant.

Commercial Lighting

Commercial buildings, such as offices, shopping malls, hotels, and hospitals, also benefit greatly from the use of LED circuits boards. In large - scale commercial applications, the energy savings and reduced maintenance costs offered by LEDs can be substantial, making them a cost - effective lighting solution.

LED circuits boards can be used to create a variety of lighting designs for commercial spaces, including general illumination, task lighting, and accent lighting. They can also be integrated with smart lighting systems, allowing for the control and automation of the lighting based on occupancy, daylight levels, and other factors.

Outdoor Lighting

Outdoor lighting applications, such as streetlights, parking lot lights, landscape lighting, and floodlights, require robust and reliable lighting solutions that can withstand harsh environmental conditions. LED circuits boards are well - suited for outdoor use, as they offer high energy efficiency, long lifespan, and resistance to weather, vibration, and shock.

LED outdoor lighting can also be designed to meet specific lighting requirements, such as brightness, color temperature, and light distribution. With the use of advanced optical components, LED outdoor lighting can provide uniform and efficient illumination, while minimizing light pollution and energy waste.

Automotive Lighting

The automotive industry has witnessed a rapid adoption of LED technology in recent years, and LED circuits boards play a crucial role in this trend. LED headlights, taillights, interior lighting, and daytime running lights are all powered by LED circuits boards, offering improved visibility, energy efficiency, and design flexibility.

LED automotive lighting can also be integrated with advanced driver - assistance systems (ADAS), such as adaptive cruise control, lane departure warning, and automatic emergency braking. By providing precise and reliable lighting, LED circuits boards can enhance the safety and performance of modern vehicles.

Specialized Lighting Applications

LED circuits boards are also used in a variety of specialized lighting applications, such as horticultural lighting, medical lighting, and aviation lighting. In horticultural lighting, LEDs are used to provide the specific wavelengths of light required for plant growth, resulting in increased crop yields and improved plant quality.

In medical lighting, LEDs are used to provide high - quality, flicker - free illumination for surgical procedures, examination rooms, and other medical applications. LED medical lighting can also be designed to meet specific color temperature and color rendering requirements, ensuring accurate diagnosis and treatment.

In aviation lighting, LEDs are used to provide reliable and energy - efficient lighting for aircraft interiors and exteriors. LED aviation lighting can also be integrated with advanced lighting control systems, allowing for the adjustment of the lighting based on the flight phase, cabin conditions, and other factors.

Market Trends of LED Circuits Boards

Growing Demand for Energy - Efficient Lighting

The increasing focus on energy conservation and environmental sustainability is driving the demand for energy - efficient lighting solutions, such as LED circuits boards. Governments around the world are implementing strict energy - efficiency regulations and incentives to promote the adoption of LED lighting, which is expected to fuel the growth of the LED circuits board market in the coming years.

Advancements in LED Technology

The continuous advancements in LED technology, such as the development of high - power, high - efficiency LEDs and the improvement of LED packaging and thermal management, are also contributing to the growth of the LED circuits board market. These advancements are enabling the development of more powerful, efficient, and reliable LED lighting systems, which are expected to expand the application scope of LED circuits boards.

Integration of Smart Lighting Systems

The integration of LED circuits boards with smart lighting systems, such as wireless control, occupancy sensing, and daylight harvesting, is becoming increasingly popular. Smart lighting systems offer a range of benefits, such as energy savings, convenience, and enhanced user experience, which is expected to drive the demand for LED circuits boards in the smart home and commercial building markets.

Growing Demand for Miniaturization and High - Density Integration

The trend towards miniaturization and high - density integration in the electronics industry is also driving the demand for smaller, more compact LED circuits boards. As the size of the LEDs and other components continues to shrink, the design and manufacturing of LED circuits boards need to adapt to accommodate these changes, which is expected to create new opportunities for innovation and growth in the LED circuits board market.

In conclusion, LED circuits boards have become an essential component in the modern lighting industry, offering a wide range of benefits, such as energy efficiency, long lifespan, design flexibility, and reliability. As the demand for energy - efficient lighting solutions continues to grow, and the advancements in LED technology and smart lighting systems continue to evolve, the future of LED circuits boards looks promising. Manufacturers and designers of LED circuits boards need to stay updated with the latest trends and technologies to meet the changing needs of the market and drive the continued growth and innovation of the LED lighting industry.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB