-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Oct 27. 2025, 13:29:57

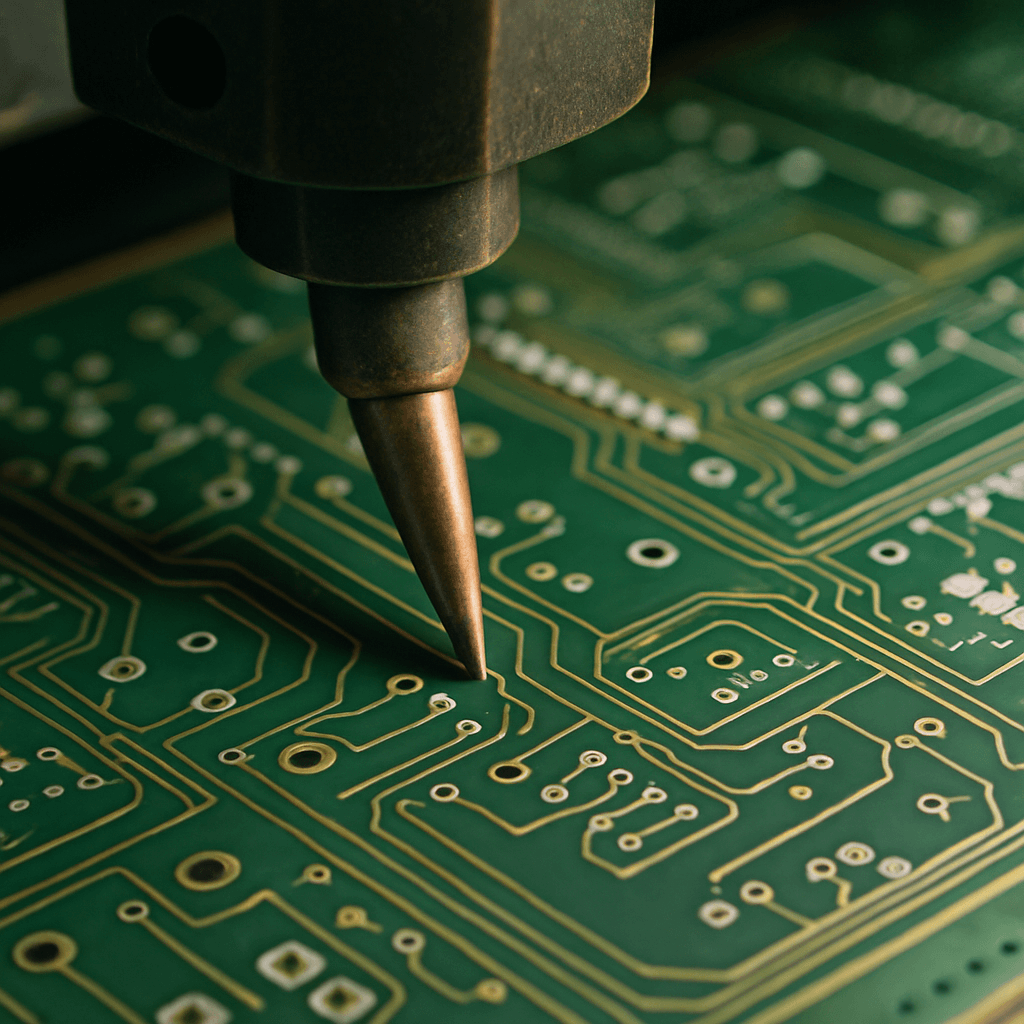

In the world of electronics, precision and quality are paramount. One of the critical aspects of ensuring these is the assembly of printed circuit boards (PCBs). Among the various techniques in PCB assembly, the 3mm counterbore process stands out for its unique benefits and applications. In this article, we'll delve into the intricacies of 3mm counterbore PCB assembly work, exploring its importance, methodology, and the advantages it brings to the manufacturing process.

Printed Circuit Boards (PCBs) are the backbone of most electronic devices. They connect various electronic components and allow them to communicate effectively. The manufacturing process of PCBs involves several steps, from design and prototyping to actual production and assembly. Each step requires meticulous attention to detail to ensure the final product meets the desired specifications.

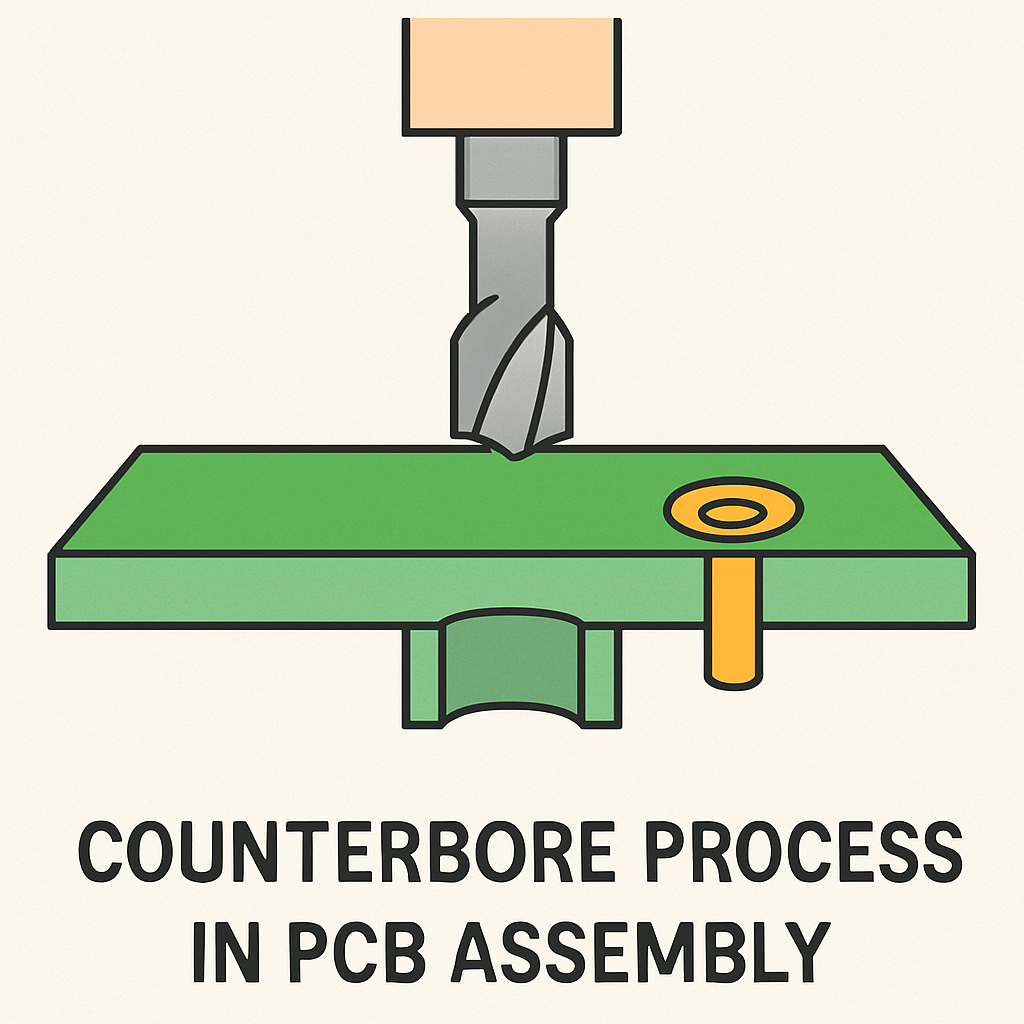

In PCB assembly, a counterbore refers to the cylindrical flat-bottomed hole that enlarges another hole. This technique is vital when you need to mount components that require a recessed area for screws or other hardware to sit flush with the board's surface. The 3mm counterbore is a specific size used in various applications, offering a balance between structural support and space efficiency.

Executing a 3mm counterbore in PCB assembly involves precision and expertise. Let's break down the process to understand how it's done.

The first step in any PCB assembly process is design and planning. Engineers utilize specialized software to design the PCB layout, ensuring that the counterbore holes are accurately positioned. This stage is crucial as it sets the foundation for the entire manufacturing process.

Once the design is finalized, the drilling phase begins. Advanced CNC machines are often used to drill the initial holes. After the primary holes are drilled, the counterbore operation is performed. This involves using a larger drill bit to create the counterbore, ensuring it is precisely 3mm in diameter.

After the counterbores are created, the components are placed onto the PCB. The counterbores allow for the secure and flush mounting of components that require screws or other hardware. Once the components are in place, soldering is performed to secure them electrically and mechanically to the board.

Quality assurance is a critical step in PCB assembly. After the soldering process, the PCBs undergo rigorous inspection and testing to ensure functionality and reliability. This step is vital to catch any defects or issues that could affect the performance of the final product.

The 3mm counterbore PCB assembly offers several advantages, making it a popular choice in various applications.

Counterbores provide enhanced mechanical stability by allowing screws and hardware to sit flush with the board's surface. This reduces the risk of components becoming loose or damaged, especially in high-vibration environments.

The flush mounting of components not only improves the aesthetic appeal of the PCB but also maximizes space efficiency. This is particularly important in compact electronic devices where space is at a premium.

The versatility of the 3mm counterbore makes it suitable for a wide range of applications, from consumer electronics to industrial machinery. Its ability to provide a secure and efficient solution for mounting components is invaluable in many fields.

While the advantages are clear, there are challenges that manufacturers may face during the 3mm counterbore PCB assembly process.

The need for precision in drilling and counterboring is paramount. Any deviation from the specified dimensions can lead to improper component mounting, affecting the PCB's overall functionality.

The additional steps involved in creating counterbores can increase both the cost and time required for PCB assembly. Manufacturers need to balance these factors with the benefits provided by the counterbore technique.

The 3mm counterbore PCB assembly is a crucial technique in modern electronics manufacturing. It offers significant benefits in terms of mechanical stability, aesthetics, and versatility, making it a valuable process in various applications. However, it also requires precise execution and careful planning to ensure successful implementation. As technology continues to advance, the role of counterbore in PCB assembly will likely evolve, further enhancing the capabilities and reliability of electronic devices.

By understanding the intricacies of 3mm counterbore PCB assembly work, manufacturers can make informed decisions that improve the quality and performance of their products, ultimately leading to greater success in the competitive electronics market.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB