-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Oct 27. 2025, 13:53:06

In the world of electronics, the design and assembly of printed circuit boards (PCBs) are crucial to the functionality and reliability of any electronic device. One aspect of PCB assembly that often goes unnoticed but is critically important is the tapped counterbore. This article will delve into what a tapped counterbore is, its significance in PCB assembly, and how it enhances the overall manufacturing process.

Printed circuit boards serve as the backbone of most electronic devices, providing a physical platform for mounting and interconnecting electronic components. PCB manufacturing involves several steps, including designing the board layout, fabricating the board, assembling components, and testing the final product.

In the PCB assembly process, precision and attention to detail are paramount. Any errors or misalignments can lead to malfunctioning devices, which is why every element of the assembly process, including the incorporation of tapped counterbores, plays a vital role.

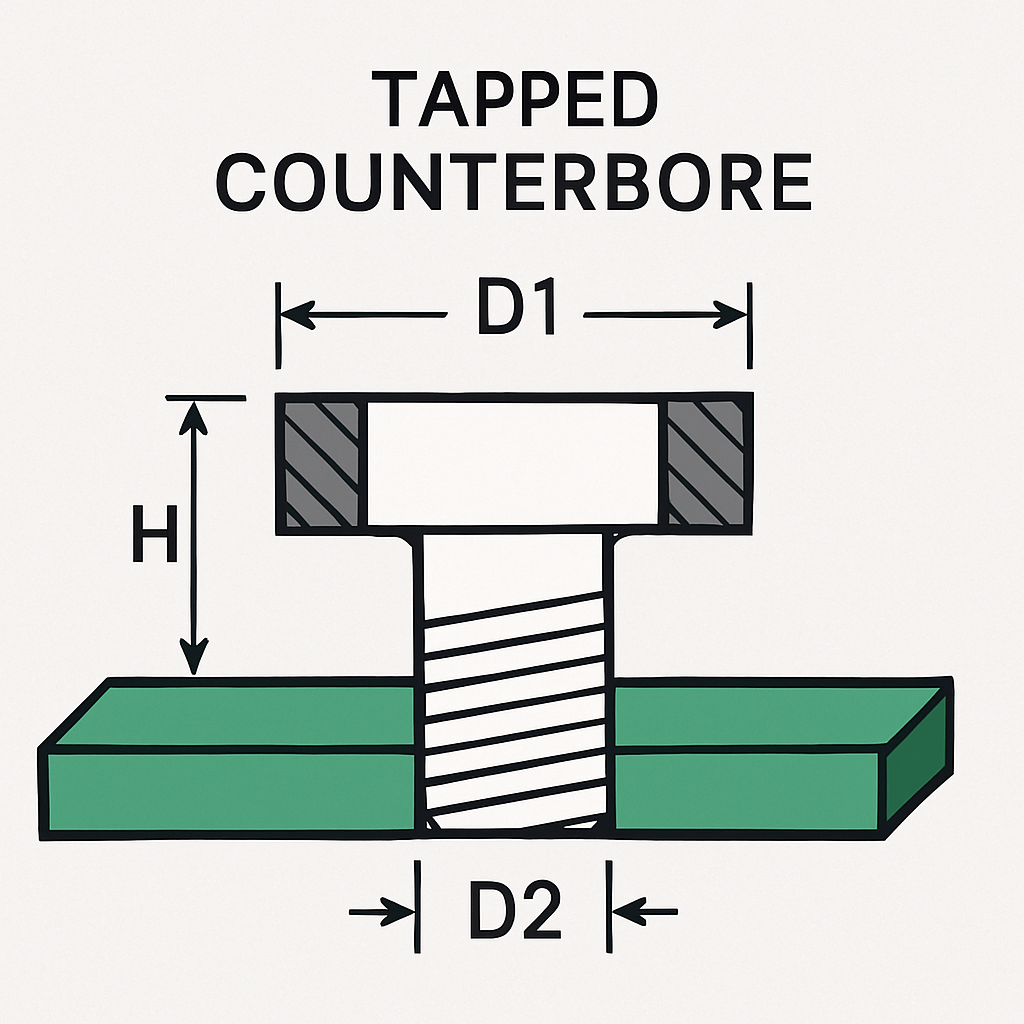

A tapped counterbore in PCB assembly refers to a hole that is drilled and then tapped to create threads. This allows for screws or bolts to be securely fastened to the PCB. The counterbore part of the term indicates that the hole is recessed, allowing the head of the screw or bolt to sit flush with or below the surface of the board.

Tapped counterbores are essential in PCB assembly for several reasons:

Secure Component Mounting: By providing threaded holes, tapped counterbores ensure that components are securely attached to the PCB, reducing the risk of loose parts that could lead to circuit failure.

Space Efficiency: The recessed nature of counterbores allows for components to be mounted closer together, optimizing the use of space on the PCB.

Enhanced Durability: Tapped counterbores distribute mechanical stress more evenly across the PCB, which can improve the overall durability of the board, especially in applications subject to vibration or mechanical shock.

Incorporating tapped counterbores in PCB design and assembly requires careful planning and execution. Here’s how they fit into the overall process:

During the design phase, engineers decide where tapped counterbores should be placed based on the components that need secure mounting. The design software allows for precise placement, ensuring that the counterbores do not interfere with other elements on the board.

Once the design is finalized, the fabrication process begins. Drilling the holes for tapped counterbores requires precision machinery capable of creating consistent, accurate holes. After drilling, the holes are tapped to create the necessary threads.

During assembly, components are mounted to the PCB using screws or bolts that fit into the tapped counterbores. This step is crucial for ensuring that all components remain securely attached throughout the device's lifecycle.

Testing follows assembly to confirm that the tapped counterbores and other elements of the PCB are functioning correctly. This step helps catch any potential issues before the device is shipped to customers.

The use of tapped counterbores in PCB assembly offers several benefits:

Improved Reliability: By ensuring secure attachment of components, tapped counterbores contribute to the overall reliability of the electronic device.

Flexibility in Design: The ability to securely mount components allows for more flexibility in PCB design, accommodating a wider range of applications and configurations.

Cost-Effective Manufacturing: Although the inclusion of tapped counterbores may add a step to the manufacturing process, the benefits of increased durability and reliability often outweigh the initial costs.

While tapped counterbores offer many advantages, there are also challenges and considerations to keep in mind:

Precision is key when drilling and tapping counterbores. Inaccurate drilling can lead to misalignment, which can affect the performance and reliability of the PCB.

The material of the PCB and the components to be mounted can affect the choice of screws or bolts used in tapped counterbores. It’s important to select materials that are compatible and capable of withstanding the intended operating conditions.

Incorporating tapped counterbores can add complexity to the PCB design process. Engineers must carefully plan the layout to ensure that counterbores do not interfere with other components or traces on the board.

Tapped counterbores are a critical element in PCB assembly, providing secure mounting for components and enhancing the reliability and durability of electronic devices. While they add an extra layer of complexity to the design and manufacturing process, their benefits in terms of reliability and design flexibility make them a valuable tool in the world of PCB manufacturing.

By understanding the role and importance of tapped counterbores, manufacturers can improve the quality and performance of their products, ultimately leading to greater customer satisfaction and a stronger competitive edge in the market.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB