-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Oct 17. 2025, 11:01:52

In the world of electronics, innovation is a constant. One area that has seen significant advancements is in the design and manufacturing of Printed Circuit Boards (PCBs). Specifically, the development of medical rigid flex PCB assembly has revolutionized how electronic components are integrated into medical devices. This article will explore the significance, process, and benefits of medical rigid flex PCBs, and how they are shaping the future of medical technology.

A rigid flex PCB is a hybrid circuit board that combines elements of both rigid and flexible PCBs. This design allows for the board to be both flexible in certain areas while maintaining rigidity in others. This unique combination offers a multitude of benefits, particularly in medical applications where space and weight are often limited.

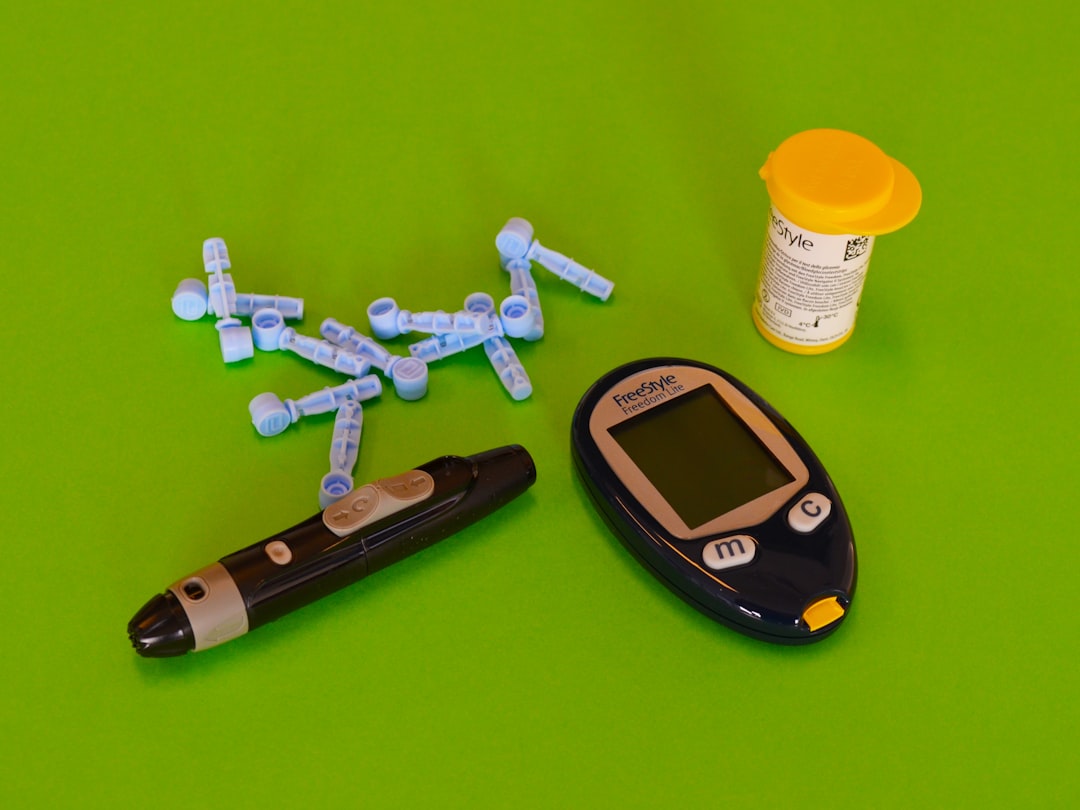

Medical devices require highly reliable and compact electronic systems. Rigid flex PCBs provide the necessary flexibility and durability. They are used in numerous medical applications, including pacemakers, hearing aids, and imaging devices, due to their ability to withstand harsh conditions and provide consistent performance.

The creation of rigid flex PCBs involves several key steps, each crucial to ensuring the final product meets the high standards required for medical applications.

The first step in the process is designing the PCB layout. Engineers use advanced software to create a prototype that meets the specific needs of the medical device. This prototype is then rigorously tested to ensure it functions correctly before moving on to full-scale production.

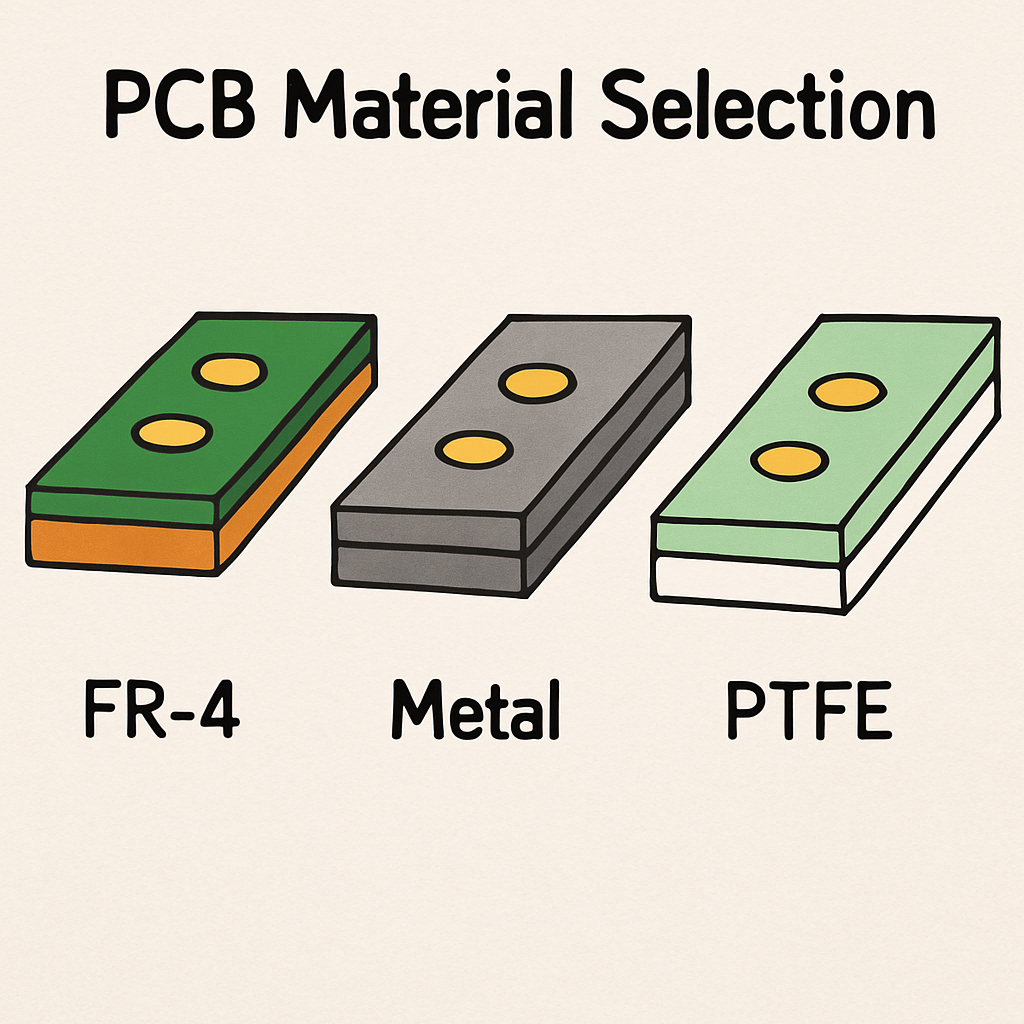

Selecting the right materials is vital. The materials must be capable of withstanding environmental stresses and remain functional over the device's life span. Common materials include polyimide for flexibility and FR4 for rigidity. The combination of these materials allows for the unique properties of rigid flex PCBs.

The next step involves the stacking of layers. Rigid flex PCBs can have multiple layers, which are carefully aligned and bonded. This process requires precision to ensure that the board functions as intended. The layers are then laminated together, creating a solid structure.

After stacking, holes are drilled into the board to allow for the placement of electronic components. These holes are then plated to ensure electrical connectivity across the board. This step is crucial for the functionality of the PCB, as it allows signals to pass between different layers and components.

Once the board is fully constructed, the assembly process begins. Components are placed onto the board and soldered into place. After assembly, the board undergoes rigorous testing to ensure it meets all necessary performance standards. This includes testing for electrical connectivity, durability, and functionality.

One of the primary benefits of rigid flex PCBs is their ability to save space and reduce weight. This is particularly important in medical devices, which often need to be compact and lightweight to be effective.

Rigid flex PCBs are highly reliable due to their robust construction and the quality of materials used. They can withstand environmental stresses and are less prone to failure, making them ideal for critical medical applications.

The design of rigid flex PCBs allows for better performance in terms of electrical connectivity and signal integrity. This ensures that medical devices operate smoothly and efficiently, providing accurate results and enhancing patient care.

When selecting PCB assembly services, it's essential to choose a provider with experience in manufacturing medical rigid flex PCBs. Look for companies that offer:

Comprehensive Design Support: They should provide assistance from the initial design phase through to final production.

Advanced Testing Capabilities: Ensure they have the facilities to conduct thorough testing to guarantee the quality and reliability of the PCBs.

Regulatory Compliance: The provider should adhere to all relevant industry standards and regulations, ensuring the PCBs are safe for use in medical devices.

The future of medical rigid flex PCBs looks promising. As technology continues to evolve, these PCBs will become even more integral to the development of advanced medical devices. Their ability to provide reliable, compact, and efficient solutions makes them indispensable in the ongoing quest to improve healthcare outcomes.

In conclusion, medical rigid flex PCB assembly is a critical component in the design and manufacture of modern medical devices. Understanding the process and benefits can help you make informed decisions when selecting PCB assembly services for your medical applications.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB