-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Oct 16. 2025, 19:27:00

The world of automotive technology is rapidly evolving, with vehicles becoming more reliant on electronic components for improved performance and safety. At the heart of these components are printed circuit boards (PCBs), crucial for the seamless operation of various automotive functions. Today, we will delve into the automotive rigid PCB assembly process, highlighting the key steps and considerations involved in circuit board production.

Rigid PCBs are essential in the automotive industry due to their durability and ability to withstand harsh conditions. Unlike flexible PCBs, rigid PCBs maintain their shape and provide a stable platform for mounting electronic components. They are used in various automotive applications, such as engine control units, infotainment systems, and advanced driver-assistance systems (ADAS).

The robust nature of rigid PCBs makes them ideal for automotive applications. They offer structural support, ensuring components remain securely attached even under extreme conditions like high temperatures and vibrations. Moreover, they facilitate complex circuitry needed for modern automotive systems, enhancing vehicle reliability and performance.

The production of automotive rigid PCBs involves several steps, each requiring precision and attention to detail to ensure quality and functionality. Let's explore the key stages of the circuit board production process.

The first step in the automotive PCB assembly process is designing the PCB layout. This involves creating a schematic of the circuit, detailing where each component will be placed and how they will be interconnected. Engineers use specialized software to design the layout, ensuring it meets the specific requirements of the automotive application.

Selecting the right materials is crucial for the performance and longevity of the PCB. Common materials used in rigid PCBs include fiberglass-reinforced epoxy laminate sheets, known as FR4, which provide excellent thermal and electrical insulation properties. The choice of material impacts the PCB's ability to withstand high temperatures and resist moisture, crucial in automotive environments.

Once the design is finalized, the next step is layering. This involves stacking multiple layers of conductive copper and insulating materials to form the PCB. Lamination is then performed, where heat and pressure are applied to bond the layers into a single, unified board. This step is critical for ensuring the PCB's structural integrity.

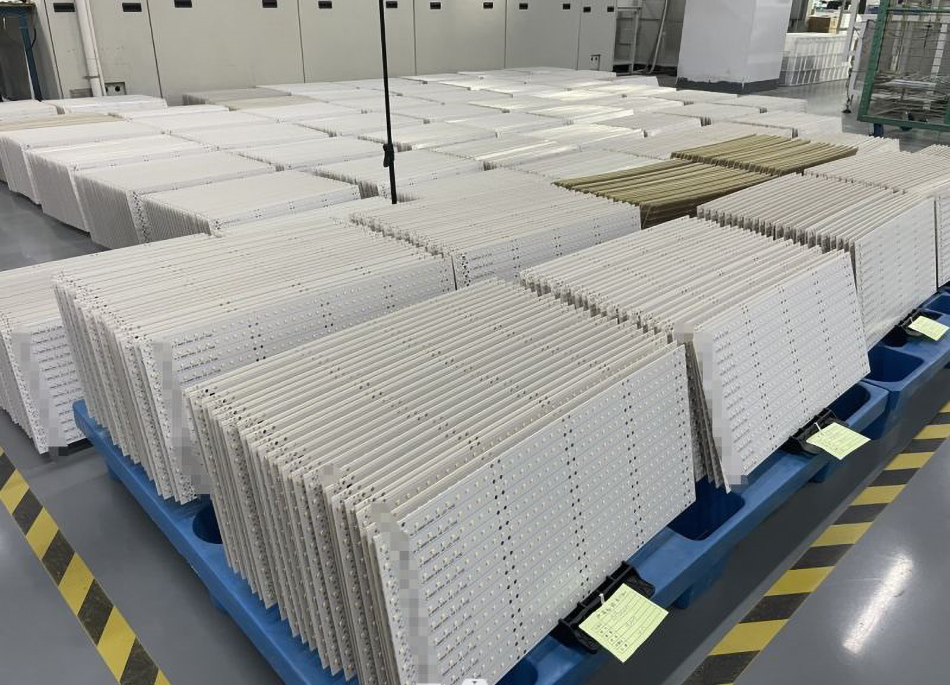

After the PCB has been produced, the assembly process begins. This involves mounting electronic components onto the board, a process that requires precision and care.

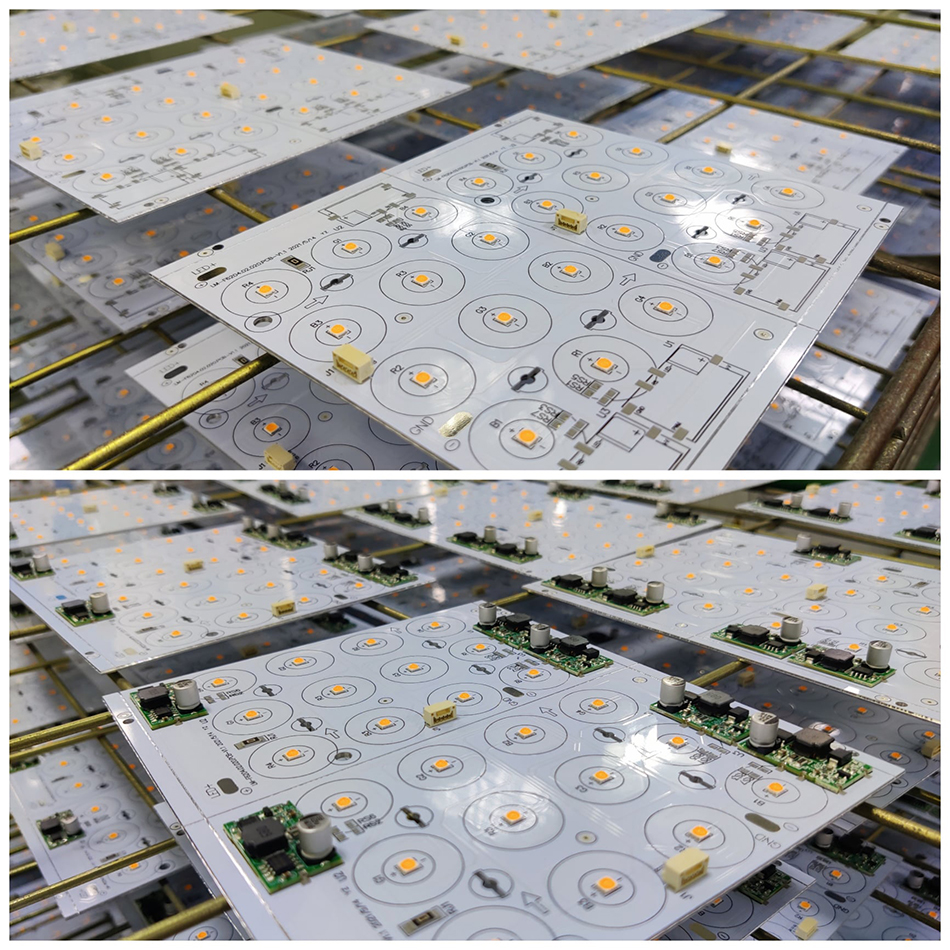

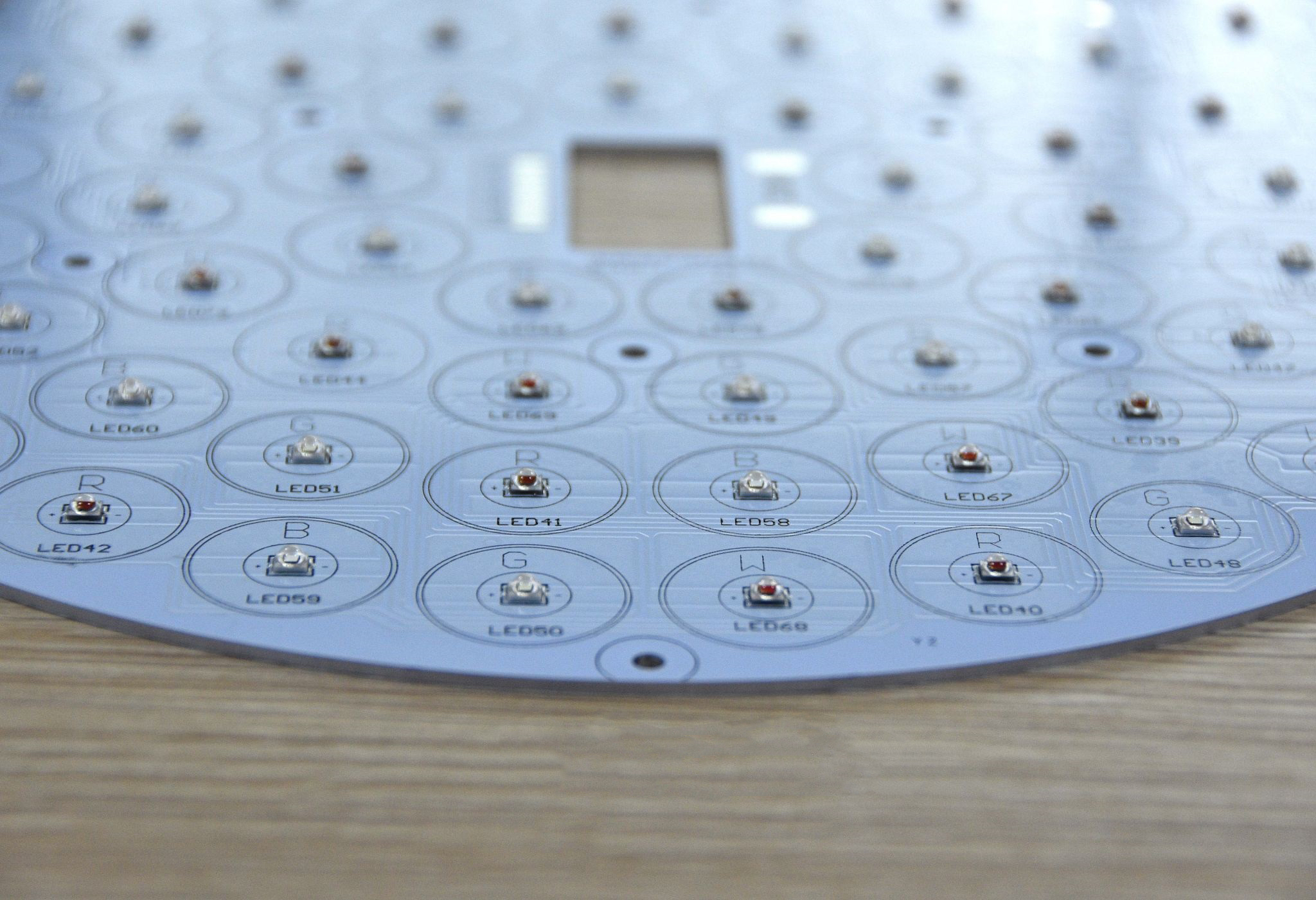

During this phase, components such as resistors, capacitors, and integrated circuits are placed onto the PCB according to the design specifications. Automated machines, known as pick-and-place machines, are often used to ensure accuracy and efficiency in placing components.

Once the components are placed, they are soldered to the board to create electrical connections. There are two primary soldering techniques used in PCB assembly: surface mount technology (SMT) and through-hole technology (THT). SMT involves placing components directly onto the board's surface, while THT requires inserting component leads through holes in the board and soldering them on the opposite side.

After assembly, the PCB undergoes rigorous inspection and testing to ensure it meets quality standards and functions correctly. Automated optical inspection (AOI) systems are used to check for defects such as misaligned components or soldering issues. Functional testing is also performed to verify that the PCB operates as intended within its automotive application.

The automotive industry presents unique challenges in PCB assembly due to the demanding environments in which vehicles operate. Ensuring the reliability and performance of PCBs in such conditions requires careful consideration of several factors.

Automotive PCBs must be able to dissipate heat effectively to prevent component failure. This is achieved through the use of thermal vias, heat sinks, and advanced materials with high thermal conductivity.

Vehicles experience constant vibrations, which can lead to mechanical stress on PCBs. To combat this, designers incorporate features such as additional support structures and flexible connectors to enhance the PCB's resilience.

As vehicles become more complex, the demand for compact electronic systems increases. This drives the need for smaller PCBs with higher component densities, posing challenges in design and manufacturing.

The automotive industry is continuously innovating, and PCB technology is no exception. Developments such as advanced substrate materials, improved thermal management techniques, and enhanced manufacturing processes are paving the way for more efficient and reliable PCBs.

New materials like metal-core PCBs (MCPCBs) offer superior thermal performance, making them ideal for high-power automotive applications. These substrates help manage heat more effectively, extending the lifespan of components.

Innovations in manufacturing, such as laser direct imaging (LDI) and high-precision drilling, are improving the accuracy and efficiency of PCB production. These advancements allow for more complex designs and tighter tolerances, essential for modern automotive systems.

The automotive rigid PCB assembly process is a complex, multi-step operation that plays a crucial role in the functionality and reliability of modern vehicles. From design and material selection to assembly and testing, each stage requires meticulous attention to detail to meet the demanding standards of the automotive industry.

As technology continues to evolve, so too will the methods and materials used in PCB assembly, driving further advancements in automotive electronics and contributing to safer, more efficient vehicles. By understanding the intricacies of this process, automotive manufacturers can continue to push the boundaries of innovation, ensuring the future of transportation is both bright and sustainable.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB