-

- PCB TYPE

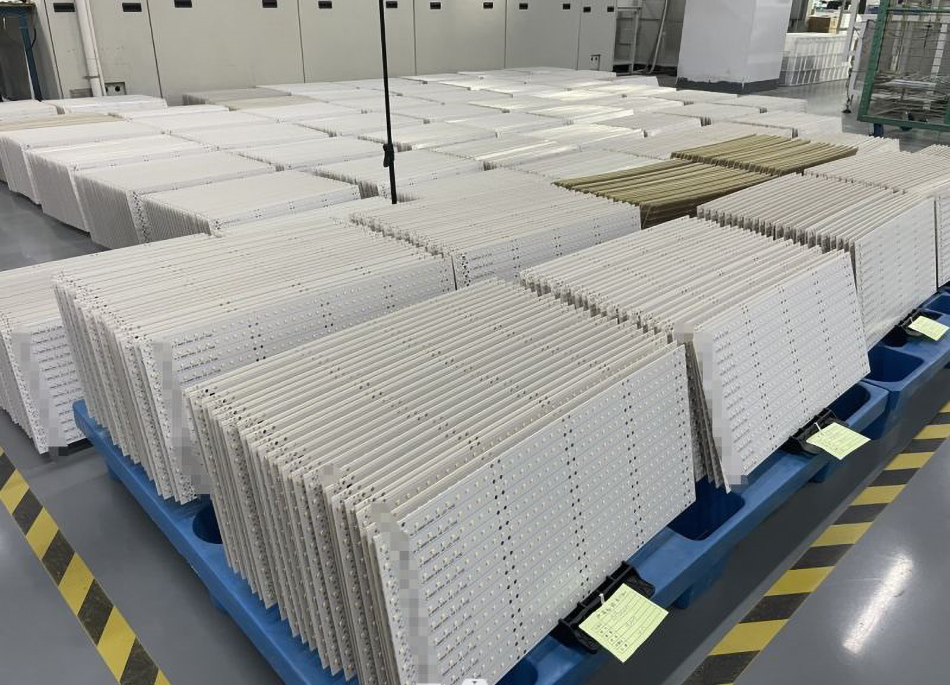

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Oct 16. 2025, 19:29:07

Printed Circuit Boards (PCBs) are the backbone of modern electronic devices. From smartphones to complex industrial machines, PCBs play a crucial role in connecting and supporting electronic components. Among the different types of PCBs, rigid PCBs are widely used due to their durability and robustness. In this guide, we'll delve into the world of rigid PCB assembly, explore the PCB fabrication process, and highlight the advantages of using professional PCB assembly services.

Understanding Rigid PCB Assembly

Rigid PCBs are made of a solid substrate material that does not bend or flex. This rigidity provides a stable platform for mounting electronic components, making them ideal for applications where durability and reliability are paramount. Let's take a closer look at what rigid PCB assembly entails.

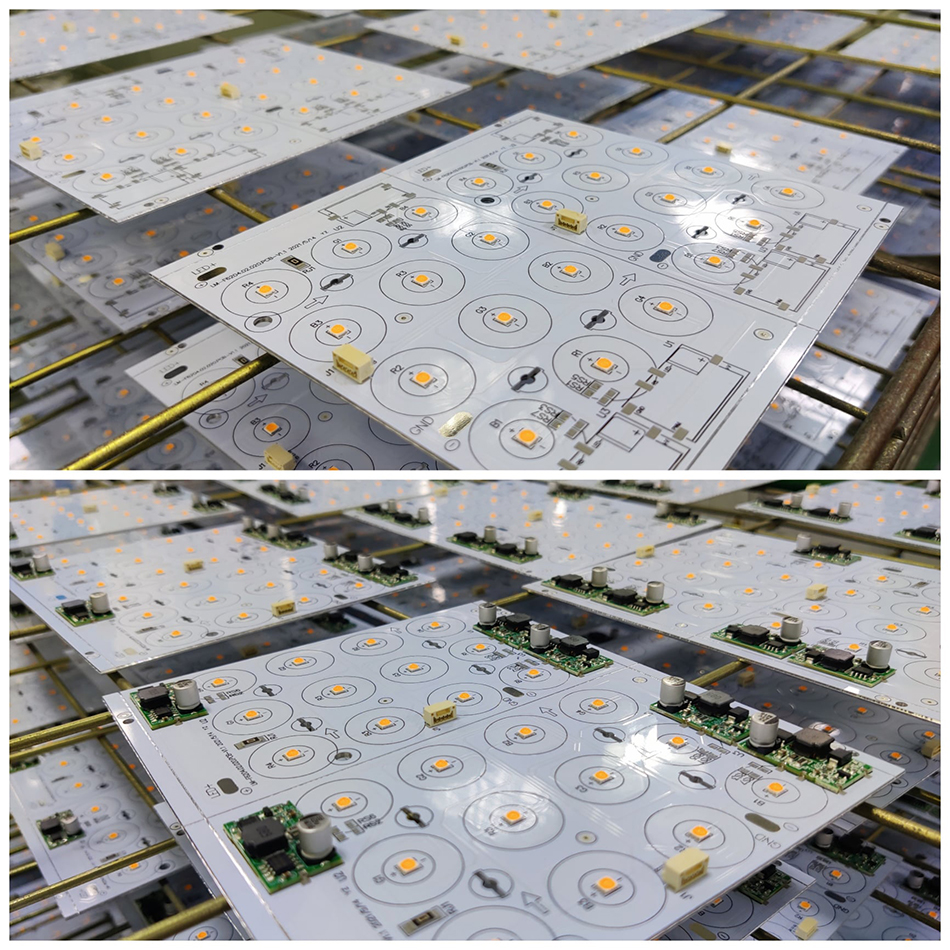

Rigid PCB assembly refers to the process of mounting electronic components onto a rigid PCB board. The assembly process involves several steps, including placing components, soldering, and testing to ensure functionality and reliability.

Rigid PCBs consist of several layers, each serving a specific function:

Substrate Layer: This is the rigid base that supports the PCB. It is typically made of fiberglass or other non-conductive materials.

Copper Layer: Conductive copper traces are etched onto the substrate to create electrical pathways.

Solder Mask: A protective layer applied over the copper traces to prevent oxidation and short circuits.

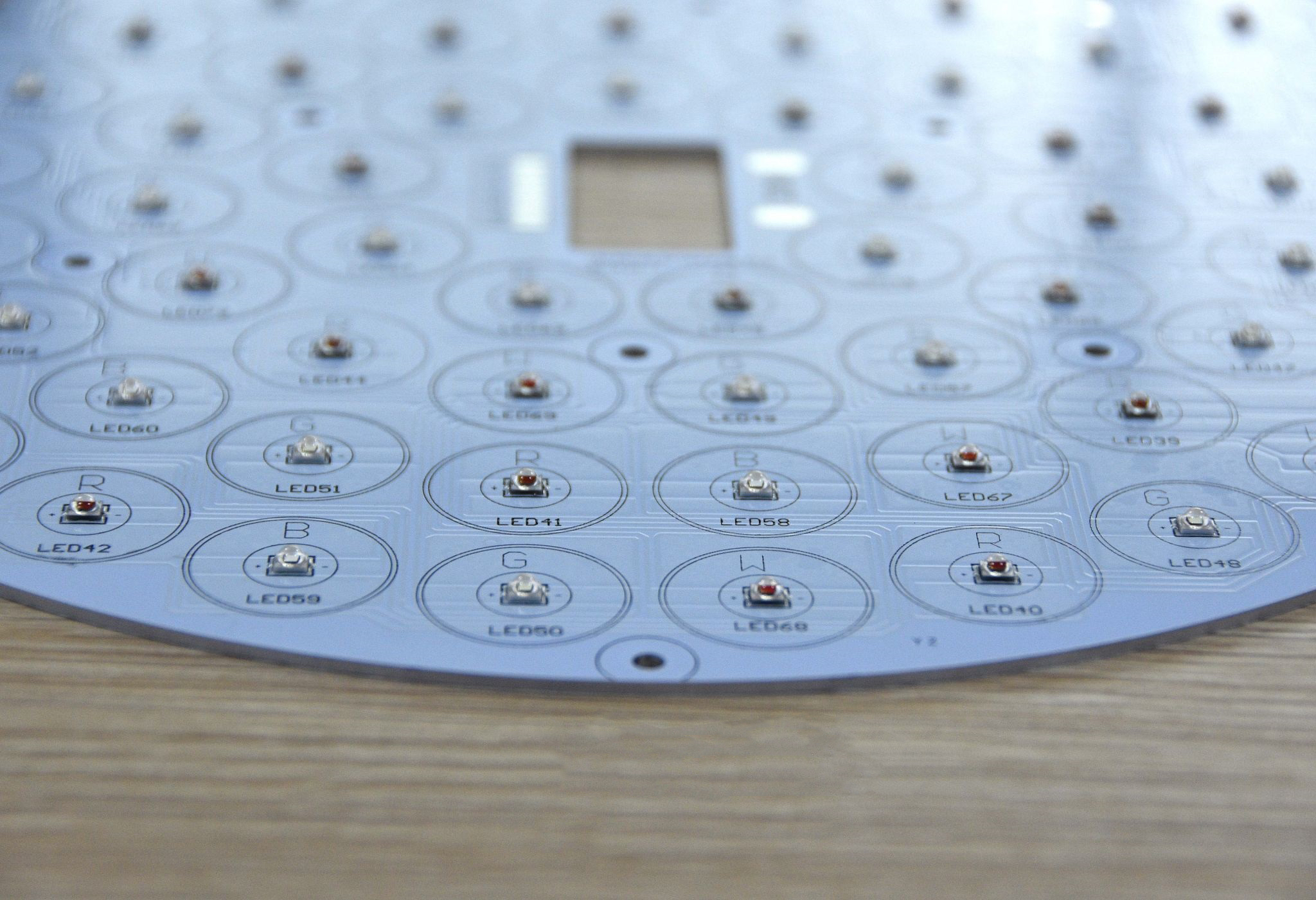

Silkscreen Layer: Used to print labels and markers on the PCB for easy identification of components.

The fabrication process for rigid PCBs involves several intricate steps to ensure precision and quality. Here's an overview of the key stages in the PCB fabrication process:

The first step in the PCB fabrication process is designing the circuit layout. Engineers use specialized software to create a schematic that outlines the placement of components and traces on the board.

Once the design is finalized, it's printed onto a specialized film that serves as a blueprint for the PCB. This film guides the etching process.

Etching involves removing excess copper from the PCB to create the desired circuit patterns. The board is coated with a photoresist material, and ultraviolet light is used to harden the areas that should remain. The unexposed areas are washed away, leaving behind the copper traces.

For multi-layer PCBs, individual layers are aligned and bonded together under heat and pressure. This step ensures that all layers are precisely stacked and secured.

Holes are drilled into the PCB to accommodate component leads and vias. The drilled holes are then plated with copper to establish electrical connections between layers.

A solder mask is applied to the PCB to protect the copper traces and prevent solder bridges during assembly. This step is crucial for ensuring the longevity and reliability of the PCB.

The final step in fabrication is applying the silkscreen layer. This involves printing component labels, logos, and other identifiers on the PCB surface.

Professional PCB assembly services play a vital role in ensuring the quality and efficiency of rigid PCB assembly. Let's explore why partnering with a reputable PCB assembly provider is essential.

PCB assembly services employ skilled technicians and advanced equipment to achieve precise component placement and soldering. This expertise minimizes the risk of errors and defects, resulting in high-quality PCBs.

Outsourcing PCB assembly to a specialized provider can be more cost-effective than setting up an in-house assembly line. Assembly services offer economies of scale, reducing production costs and saving valuable time.

by Học Viện Chăm Sóc Sắc Đẹp Á Âu (https://unsplash.com/@hocvienchamsocsacdep)

Reputable PCB assembly providers adhere to strict quality control standards. They conduct rigorous testing and inspections to ensure that each PCB meets industry specifications and performs reliably.

PCB assembly services offer customization options to meet specific project requirements. Whether you need prototypes or large-scale production runs, assembly providers can tailor their services to suit your needs.

Rigid PCBs offer several advantages that make them a popular choice for various applications. Here are some key benefits:

The rigid substrate of these PCBs provides exceptional durability, making them suitable for environments where mechanical stress is a concern. They maintain their structural integrity even under challenging conditions.

Rigid PCBs can accommodate a high density of components, allowing for complex circuit designs in a compact form factor. This is particularly beneficial in applications with limited space.

The stability of rigid PCBs ensures consistent electrical performance, reducing the risk of signal interference and degradation. This reliability is crucial for critical applications such as medical devices and aerospace technology.

Rigid PCB assembly is a fundamental process that underpins the functionality of countless electronic devices. Understanding the PCB fabrication process and the benefits of professional PCB assembly services can empower you to make informed decisions for your projects. Whether you're a seasoned engineer or a newcomer to the world of electronics, rigid PCBs offer a reliable and efficient solution for your circuit design needs. By leveraging the expertise of PCB assembly services, you can ensure the success and longevity of your electronic products.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB