-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 16. 2025, 11:53:55

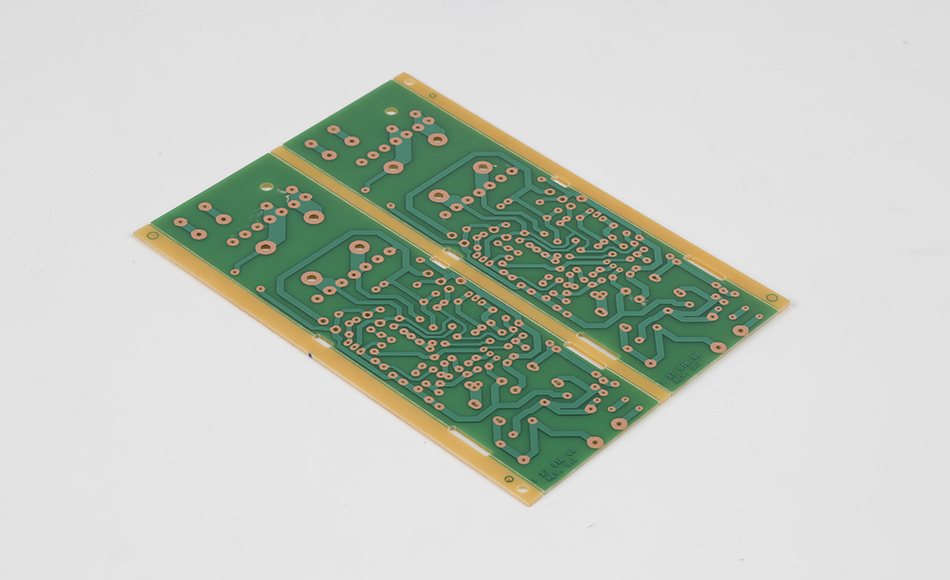

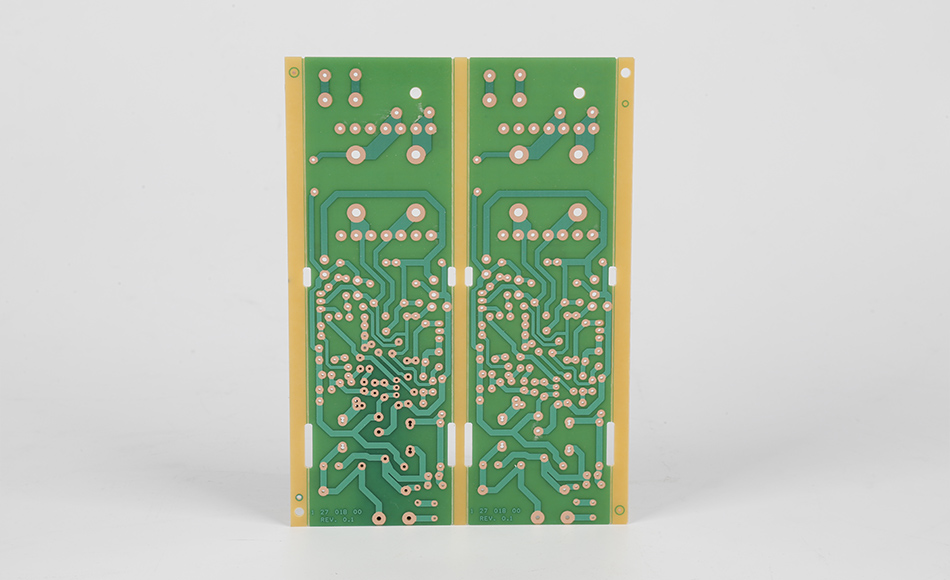

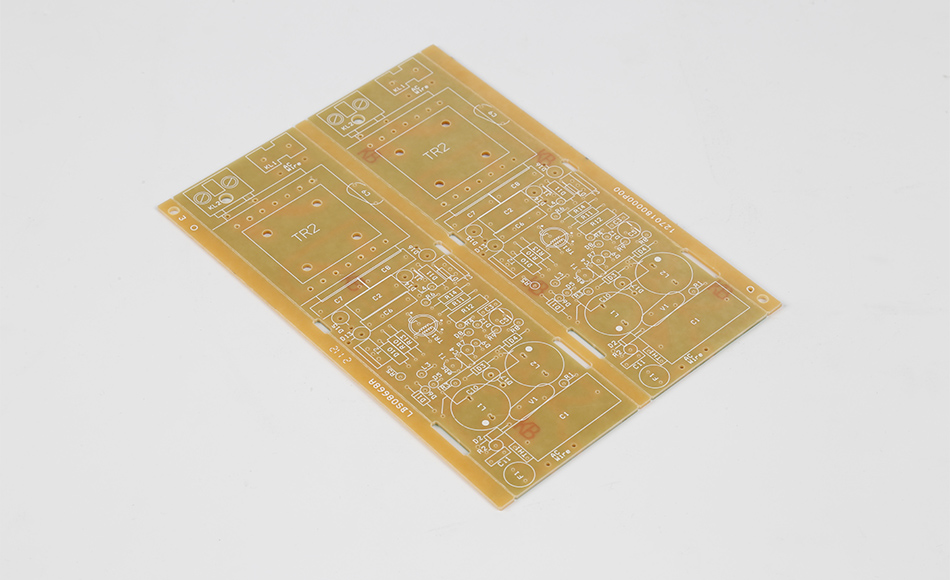

CEM3 PCB has emerged as a cornerstone of accessible electronics, providing a cost-effective yet reliable platform for a vast array of devices. As a printed circuit board built from Composite Epoxy Material-3, it occupies a unique space between budget-friendly paper-based substrates and high-performance FR4, offering a pragmatic blend of mechanical stability, electrical insulation, and flame resistance. This balance has made CEM3 PCBs indispensable in industries ranging from consumer electronics to light industrial automation, where performance requirements are moderate but reliability and cost-efficiency are non-negotiable. This article explores the unique attributes of CEM3 PCBs, their role in democratizing technology, design considerations for optimal performance, and their evolving applications in emerging markets, highlighting how they bridge the gap between functionality and affordability.

CEM3 PCBs stand out in the electronics landscape due to a combination of material properties and practical advantages that address the needs of mass-market and niche applications alike:

Unlike specialized PCBs engineered for extreme conditions, CEM3 PCBs are designed for everyday use. Their core properties—including a temperature range of -30°C to 105°C, UL94 V-0 flame resistance, and stable dielectric performance up to several hundred megahertz—align perfectly with the requirements of devices like home appliances, office equipment, and basic sensors. For example, a CEM3 PCB in a coffee maker control panel reliably handles temperature fluctuations during brewing cycles without the need for the high-temperature tolerance of FR4, reducing unnecessary costs.

The hybrid structure of CEM3—non-woven glass fiber core with woven glass fabric outer layers—reduces raw material and manufacturing expenses. The non-woven core absorbs epoxy resin efficiently, minimizing waste, while the simplified lamination process (compared to FR4) lowers production time and energy use. These savings translate to more affordable end products, making technology accessible to broader markets. For instance, CEM3 PCBs enable budget-friendly smart thermostats, ensuring energy-efficient home technology is within reach for average consumers.

CEM3 PCBs are compatible with a wide range of production processes, from low-volume prototyping to medium-scale manufacturing. Their surface smoothness allows for consistent copper etching, while their moderate rigidity simplifies handling during assembly. This versatility makes them a favorite among startups and small manufacturers, who can iterate on designs without investing in specialized production equipment.

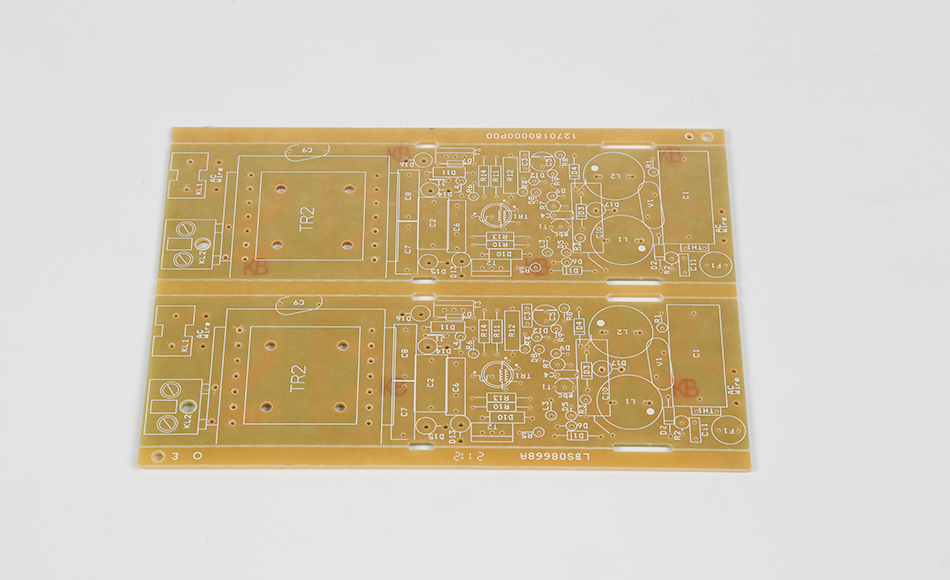

Maximizing the performance of CEM3 PCBs requires thoughtful design that aligns with their material characteristics:

CEM3 PCBs support both through-hole and surface-mount components, but designers must consider the material’s load-bearing capacity. Heavy components, such as large capacitors, should be placed near mounting holes or reinforced with adhesive to prevent substrate warping. Heat-generating components, like small power transistors, should be spaced to avoid localized hotspots, as CEM3’s thermal conductivity is lower than FR4’s. For example, in a desktop printer PCB, power drivers for the paper feed motor are positioned away from sensitive sensor circuits to prevent heat-induced signal interference.

In low-to-moderate frequency applications, CEM3’s dielectric properties ensure reliable signal transmission. However, designers should avoid overly fine traces (below 0.1mm) to prevent etching inconsistencies, and maintain adequate spacing between high-voltage and low-voltage traces to prevent arcing. For audio equipment PCBs, where signal clarity is critical, CEM3’s stable dielectric constant minimizes distortion, making it a suitable choice for amplifier circuits.

While CEM3 PCBs resist moderate moisture and dust, additional protection may be needed for harsh environments. Conformal coating—a thin polymer layer applied to the PCB surface—enhances resistance to humidity and chemical exposure, extending lifespan in applications like outdoor security cameras or industrial sensors. This simple modification allows CEM3 PCBs to punch above their weight in slightly more demanding settings.

CEM3 PCBs power a diverse range of devices, each leveraging their unique combination of properties:

Home Appliances: Refrigerators, microwaves, and washing machines rely on CEM3 PCBs for control systems. These PCBs manage temperature regulation, motor operation, and user interfaces, withstanding the daily wear and tear of household use.

Personal Devices: Low-power gadgets like electric toothbrushes, portable fans, and digital scales use CEM3 PCBs for their lightweight design and energy efficiency. The material’s electrical insulation ensures safe operation in close proximity to users.

Printers and Scanners: CEM3 PCBs coordinate motor movements, sensor inputs, and data processing in these devices. Their mechanical stability resists vibrations from paper feed mechanisms, ensuring consistent performance.

POS Systems: Point-of-sale terminals use CEM3 PCBs for their durability in high-use retail environments. The material’s flame resistance adds a safety layer in busy stores where electrical equipment is in constant use.

Basic Sensors: Temperature, humidity, and motion sensors deployed in smart buildings use CEM3 PCBs for their cost-effectiveness. These PCBs process analog signals and transmit data wirelessly, operating reliably in indoor environments.

Lighting Controls: LED driver circuits in commercial lighting systems leverage CEM3’s stable electrical performance to regulate current, ensuring consistent brightness and energy efficiency.

CEM3 PCBs are widely used in in-car electronics, such as infotainment systems, window controls, and seat heaters. Their flame resistance meets automotive safety standards, while their ability to withstand temperature swings from -30°C to 85°C ensures reliability in extreme weather conditions.

CEM3 PCBs outperform alternatives in specific scenarios, making them the optimal choice for many applications:

FR4 offers higher mechanical strength and thermal resistance but at a 30–50% higher cost. For devices operating in moderate environments, CEM3 delivers comparable performance at a lower price. For example, a smart speaker’s control PCB functions identically on CEM3 as on FR4, with no impact on sound quality or connectivity.

CEM1 uses a paper core, making it cheaper but prone to moisture absorption and heat damage. CEM3’s glass fiber reinforcement eliminates these issues, extending lifespan in humid environments like kitchens or bathrooms. A CEM3 PCB in a shower timer, for instance, resists steam-induced degradation, whereas a CEM1 PCB would likely fail within months.

Flexible PCBs (polyimide-based) are designed for curved surfaces but are more expensive and less rigid. CEM3 PCBs are preferable for flat, rigid designs, such as control panels, where stable component mounting is critical.

Recent advancements are expanding the utility of CEM3 PCBs, ensuring their relevance in evolving electronics markets:

Environmental regulations have driven the development of halogen-free CEM3 PCBs, which replace brominated flame retardants with phosphorus-based alternatives. These formulations meet strict eco-standards (e.g., EU RoHS) without sacrificing flame resistance, making them suitable for environmentally conscious markets.

New CEM3 formulations with higher glass transition temperatures (Tg 130–140°C) are enabling use in slightly more demanding applications, such as small industrial motor controllers. These variants retain cost advantages while offering improved performance in elevated temperature environments.

CEM3 PCBs are compatible with emerging manufacturing technologies like 3D printing of solder masks and automated optical inspection, reducing production errors and accelerating time-to-market for new devices. This integration ensures CEM3 remains a viable choice as electronics manufacturing becomes more digitized.

CEM3 PCB represents the democratization of electronics, providing a reliable, cost-effective platform that enables innovation across industries. Its balanced performance, manufacturing versatility, and affordability make it indispensable for devices that power daily life—from home appliances to office equipment and emerging IoT gadgets. By aligning material properties with real-world requirements, CEM3 PCBs prove that advanced technology doesn’t need to come with a premium price tag. As formulations evolve and manufacturing processes advance, CEM3 PCBs will continue to play a critical role in making technology accessible, sustainable, and reliable for generations to come. For engineers and manufacturers, CEM3 PCBs are more than a component—they are a catalyst for inclusive innovation.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB