-

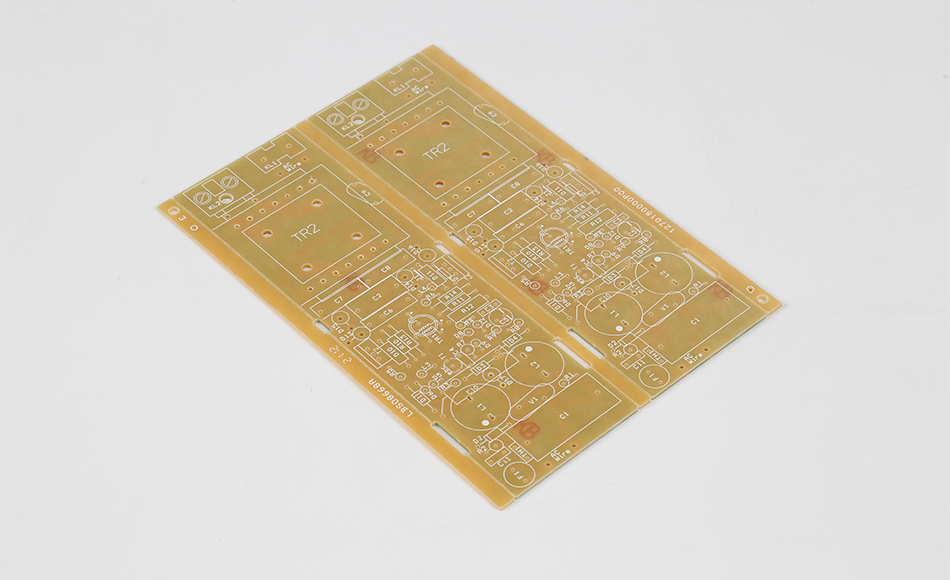

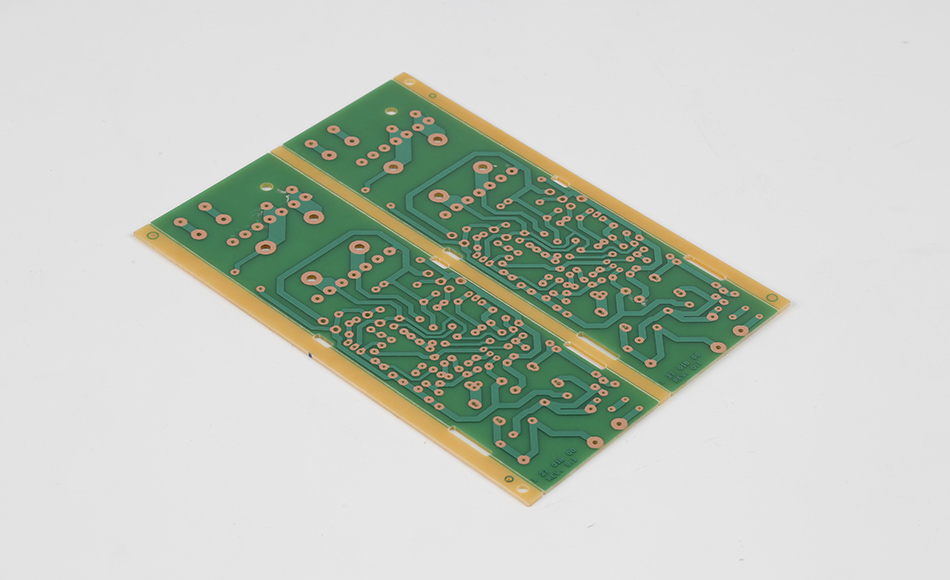

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 29. 2025, 20:32:46

CEM3 PCB is a versatile substrate bridging low-cost/low-performance CEM1 and high-cost specialized substrates (high-frequency FR4, ceramic). It balances electrical insulation, mechanical stability, and cost-effectiveness, making it ideal for mid-tier electronics (industrial controls, consumer appliances, automotive auxiliaries).

Engineers face challenges: generic CEM1 lacks durability for harsh conditions, while specialized substrates exceed mid-volume budgets. CEM3 solves this with customizable properties (adjustable dielectric behavior, manufacturing compatibility) tailored to applications without sacrificing affordability.

This article explores CEM3’s adaptive attributes, industry applications, design optimizations, and future trends—supporting engineers building flexible, cost-efficient systems.

CEM3 PCB’s versatility stems from three key adaptive attributes—tunable material properties, manufacturing flexibility, and environmental resilience—meeting diverse electronic system demands.

CEM3’s dielectric characteristics adjust during manufacturing, suiting low-speed analog and moderate-speed digital circuits:

Dielectric Constant (Dk) Customization: Modifying epoxy resin-glass fiber ratio tunes Dk to 4.2–5.0. Lower Dk (4.2–4.5) fits consumer appliances (washing machine controls) with moderate signals; higher Dk (4.6–5.0) enhances stability for industrial systems with multiple sensors. This avoids CEM1’s fixed Dk (~4.8) or specialized FR4’s rigidity.

Dielectric Loss (Df) Optimization: Refining resin minimizes Df (<0.02 at 1 MHz) for long-signal-path apps (smart meters). Less demanding uses (lighting controls) accept slightly higher Df (<0.025) for cost savings.

Insulation Resistance Stability: Hydrophobic additives boost insulation resistance (>10¹³ Ω·cm after 1,000 hours at 85°C/85% RH) for moist environments (outdoor IoT sensors). Unlike CEM1, it avoids insulation degradation in humidity.

CEM3’s compatibility with standard/specialized processes adapts to design complexity:

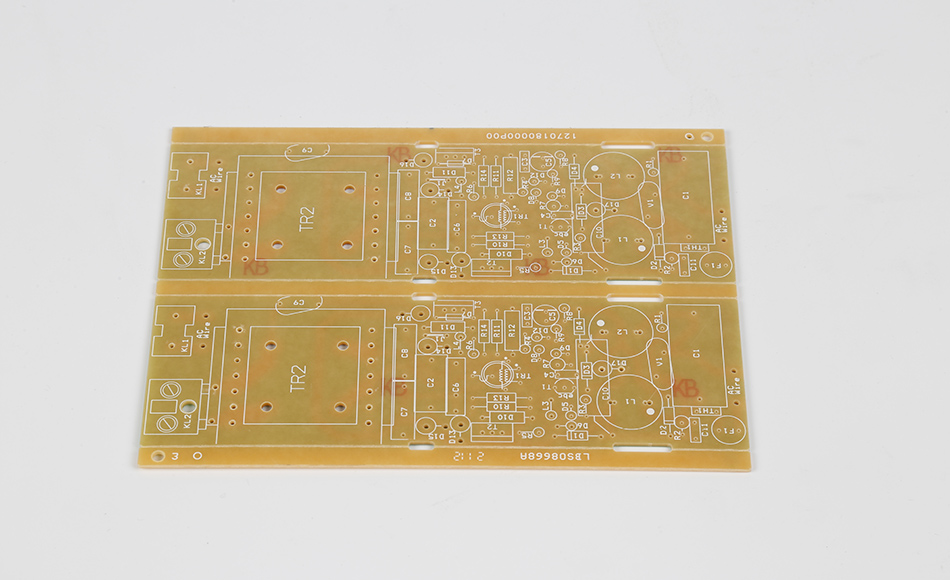

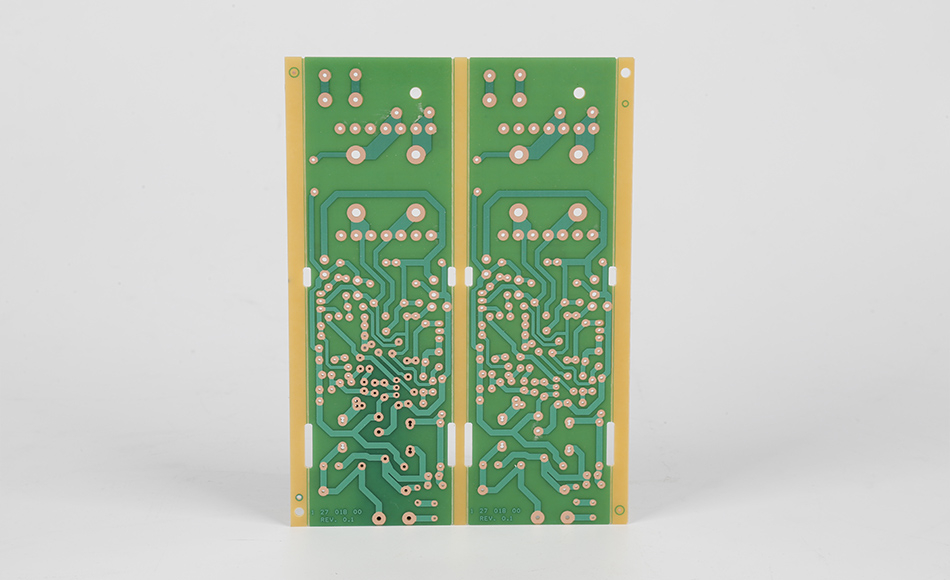

Layer Count Versatility: Supports 1–12 layers. Single-layer CEM3 works for basic fan controls; 6-layer designs suit automotive infotainment (multiple chips). Unlike CEM1 (limited to 1–4 layers), no substrate switch is needed when scaling complexity.

Component Compatibility: Flat surface (Ra < 1.0μm) and stable CTE (~16 ppm/°C X-Y) enable reliable soldering of through-hole (industrial potentiometers) and fine-pitch SMDs (0.4mm). It integrates 0.5mm-pitch microcontrollers and through-hole connectors—critical for compact systems.

Custom Surface Finishes: Supports HASL (cost-effective for high-volume consumer goods), ENIG (long shelf life for medical spares), and OSP. Adapts to assembly processes and storage needs.

CEM3 withstands diverse stressors, fitting industries from manufacturing to consumer electronics:

Thermal Stability: Tg (120–130°C, adjustable via resin) operates up to 105°C (automotive window controls). High-Tg variants (140°C) handle 125°C, avoiding expensive high-Tg FR4.

Vibration Resistance: Flexural strength (~450 MPa) and strong layer adhesion prevent trace cracking in industrial pumps/portable tools. A study showed 95% survival after 10,000 hours of vibration (10–500 Hz) vs. 75% for CEM1.

Chemical Resistance: Epoxy matrix resists industrial chemicals (mineral oil) and household cleaners, suiting kitchen appliance controls and industrial sensors. Outperforms CEM1, which degrades in harsh substances.

CEM3’s adaptive attributes make it a staple across industries with unique needs. Below are key use cases solving sector-specific challenges.

Industrial controls (PLCs, motor drives) need PCBs that withstand factory conditions (temperature swings, vibration) and fit mid-volume budgets. CEM3 delivers:

Harsh Environment Endurance: Operates -40°C to 105°C; a CEM3 motor drive ran 24 months in 40°C–85°C factories without failure (CEM1 failed at 18 months due to vibration).

Multi-Functional Support: Tunable Dk (4.2–5.0) ensures signal integrity for analog sensors and digital communication (Modbus), avoiding CEM1’s interference issues.

Mid-Volume Cost Savings: Costs 30–40% less than high-Tg FR4. A PLC manufacturer cut PCB costs by 25% with no more field failures.

Case Study: A global automation firm used 4-layer CEM3 PLC boards (8 analog inputs, 32-bit MCU, 4 relays). After 18 months in 50 factories, failure rates dropped from 5.3% (CEM1) to 2.1%. \(1.20/unit savings yielded \)60k/year for 50,000 units.

Consumer appliances (washing machines, microwaves) need low-cost, compact, humidity-resistant PCBs. CEM3 adapts:

High-Volume Efficiency: Compatible with high-speed manufacturing (AOI, mass lamination) for 95%+ yields. A washing machine maker cut scrap by 15% vs. CEM1 (more consistent properties).

Compact Design: Dense component layouts (0.5mm SMDs + through-hole) reduce size—air conditioner controls are 20% smaller than CEM1 equivalents.

Humidity Resistance: Low moisture absorption (<1.5% 24h boiling water) prevents insulation degradation. Microwave boards had 98% 5-year survival in humid kitchens vs. 82% for CEM1.

Result: A top appliance brand used CEM3 for smart washing machine controls (touchscreen, motor driver, Wi-Fi) in 120mm×80mm (15% smaller than CEM1). Costs fell 18%, warranty claims dropped 30%.

Automotive auxiliaries (window controls, seat heaters) need PCBs that meet IATF 16949 and withstand temperature cycles/vibration. CEM3 delivers:

Thermal Cycle Reliability: Withstands 1,000 -40°C–125°C cycles (exceeds 800-cycle auto requirement); a window control PCB passed 1,500 cycles.

Vibration/Shock Resistance: No trace damage in 100,000 km road tests (seat heater modules); CEM1 had 8% failures.

Chemical Compatibility: Resists engine oil/coolants; a lighting control PCB survived 500 hours of oil exposure (uncoated CEM1 failed at 300 hours).

Case Study: An auto Tier 2 supplier used CEM3 for seat heater modules (1,200 thermal cycles, 100k km vibration, chemical tests). Failure rates dropped from 4% (CEM1) to 0.5%. The automaker approved CEM3 for all models, boosting supplier revenue by 20%.

Targeted design enhances CEM3’s adaptability. Below are strategies for tailoring it to use cases.

Industrial systems handle analog/digital signals—designs maintain integrity:

Trace Routing for Noise Reduction: 2–3mm wide/short analog traces minimize noise. 3x trace width separation (0.6mm for 0.2mm digital traces) cuts cross-talk. A CEM3 PLC with separated traces reduced sensor noise by 60%.

Ground Plane Design: Multi-layer boards use solid ground planes; single-layer designs use ground pours (single ground point) to avoid loops. A fan control PCB with ground pours had 40% less EMI, meeting EMC standards.

Impedance Matching: Calculate trace widths (CEM3 Dk ~4.5) for 120Ω CAN bus. Matched traces reduced reflections by 50%, improving factory communication reliability.

Automotive apps need to withstand thermal/vibration/chemical stress:

Thermal Relief for Power Components: Thermal relief pads connect relays to copper planes, reducing solder stress. A seat heater module with pads cut solder failures by 70% in thermal cycles.

Vibration-Resistant Mounting: Adhesive-backed components/additional solder fillets secure heavy parts (power connectors). A window control PCB had no detachment in 100k km tests (3% for non-adhesive designs).

Chemical Barriers: Polyurethane conformal coating protects near engine bays. A lighting control PCB with coating survived 500 hours of oil exposure (uncoated failed at 300 hours).

Consumer goods need compact, low-cost PCBs:

Component Density Optimization: Double-sided CEM3 reduces size—microwave controls were 30% smaller than single-sided designs.

Cost-Effective Layers: Use minimum layers (single-layer for toasters, 4-layer for smart fridges). A coffee maker 2-layer PCB cost 25% less than 4-layer alternatives.

Standardized Components: 0805 SMDs avoid custom tooling. A blender PCB using standard parts was 15% cheaper than custom-sized designs.

Example: A designer optimized a CEM3 PCB for a smart microwave: double-sided layout (30% smaller than single-sided), 2-layer count (20% cost savings vs. 4-layer), and standard 0805 SMDs. The PCB integrated a touchscreen, inverter, and Wi-Fi module in 100mm×70mm, meeting the appliance’s tight enclosure limits. Production yields reached 97%, and warranty claims for control boards dropped by 28%.

As electronics evolve (miniaturization, sustainability, smart integration), CEM3 adapts to new demands. Below are key trends:

Wearable industrial sensors and mini IoT devices need smaller PCBs. CEM3 evolves:

Ultra-Thin Variants: 0.2–0.4mm thin-core CEM3 retains 85% mechanical strength. A mini industrial temperature sensor using 0.3mm CEM3 cut PCB size by 50% while handling 10W component heat.

High-Density Interconnect (HDI) Compatibility: Improved drilling capabilities (0.1mm holes) enable HDI CEM3 PCBs. A mini IoT gateway used HDI CEM3 to fit 4G/Wi-Fi modules in 80mm×50mm, 30% smaller than standard CEM3.

Sustainability is critical—CEM3 reduces environmental impact:

Recycled Materials: 25% recycled glass fibers (from wind turbine blades) cut carbon footprint by 20% without performance loss.

Bio-Based Resins: Plant-derived epoxy (castor oil) replaces petroleum-based resin. Retains dielectric stability and adds biodegradability at end-of-life.

Energy-Efficient Production: Solar-powered lamination ovens reduce manufacturing energy use by 25% vs. traditional processes.

IoT and AI drive demand for smart PCBs. CEM3 integrates with these technologies:

Embedded Sensors: Thin-film temperature/humidity sensors embedded in CEM3 layers monitor PCB health. A smart factory PLC using this detected overheating 30 minutes early, preventing downtime.

Thermal Management Enhancements: Thermally conductive fillers (boron nitride) boost CEM3’s conductivity by 30%, supporting 5G small cell modules (higher heat output) without switching to specialized substrates.

CEM3 PCB stands out as a adaptable, cost-effective substrate for mid-tier electronics, balancing performance, flexibility, and affordability. Its tunable dielectric properties, manufacturing versatility, and environmental resilience make it suitable for industrial controls, consumer appliances, and automotive auxiliaries—filling gaps left by CEM1 and specialized substrates.

Real-world applications prove its value: lower failure rates, smaller designs, and significant cost savings. Targeted design strategies—signal integrity optimization, durability enhancements, size/cost minimization—unlock its full potential, ensuring it meets diverse application needs.

As electronics evolve, CEM3 adapts: miniaturized variants, sustainable materials, and smart integration keep it relevant for next-gen systems. For engineers building flexible, reliable, and cost-efficient electronic systems, CEM3 PCB remains a strategic choice—delivering consistent performance across industries and driving innovation in mid-tier electronics.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB