-

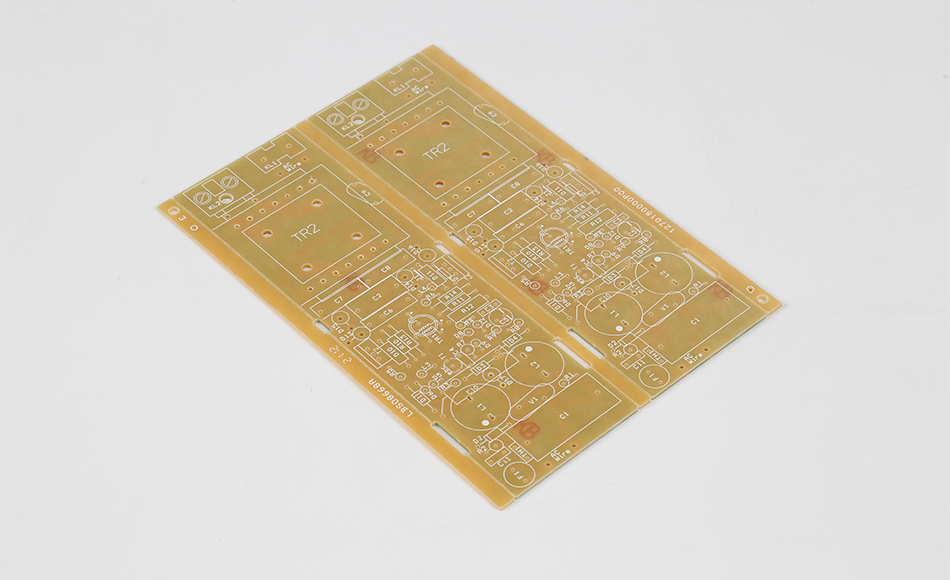

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 30. 2025, 14:40:53

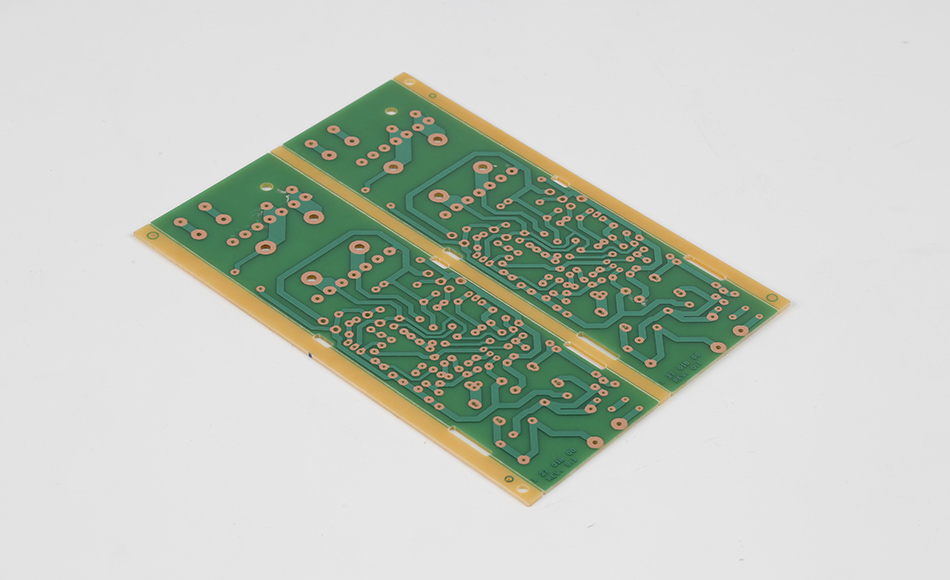

LED Backlight CEM3 PCB Suppliers are critical to the performance and scalability of LED backlight modules—essential for displays in TVs, automotive infotainment, laptops, and wearables. Unlike generic CEM3 PCB suppliers, those specializing in LED backlights address unique demands: uniform light distribution, thermal management for dense LED arrays, and compatibility with high-volume production lines.

LED backlight modules depend on PCBs to mount LEDs, distribute power, and ensure consistent light output. Standard CEM3 PCBs often fail here: poor flatness causes LED misalignment (ruining uniformity), while inadequate thermal paths lead to LED overheating (shortening lifespan). Specialized suppliers resolve these gaps by tailoring CEM3’s properties to backlight needs, balancing cost-effectiveness with precision for light uniformity and thermal stability.

This article explores the core capabilities of top LED Backlight CEM3 PCB Suppliers, their role in optimizing backlight performance, real-world case studies, and adaptation to trends like Mini/Micro LED—providing actionable insights for display manufacturers aiming to enhance quality, cut costs, and scale efficiently.

Top LED Backlight CEM3 PCB Suppliers stand out by mastering capabilities tailored to LED backlight demands—focused on uniformity, thermal management, and mass production reliability. These go beyond generic CEM3 supply, directly impacting end-display quality and lifespan.

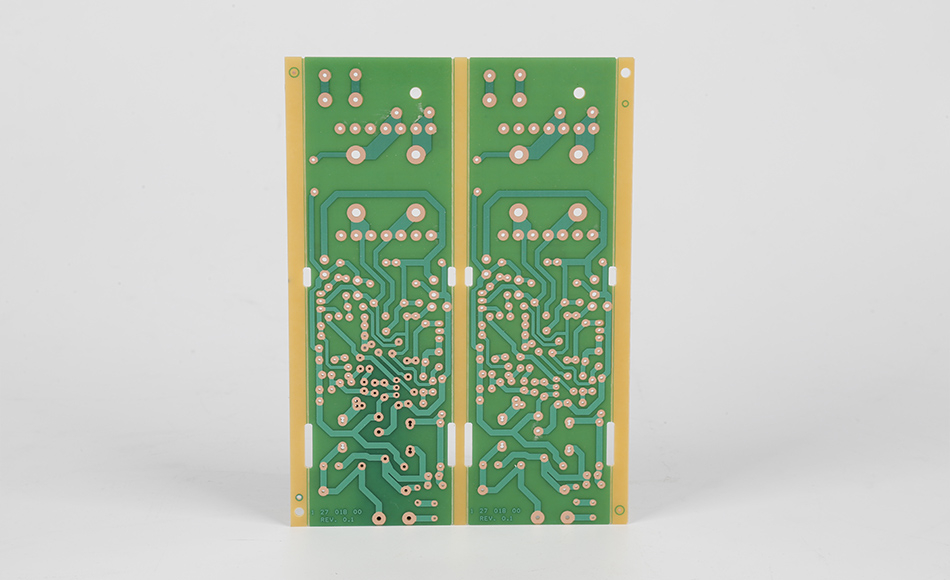

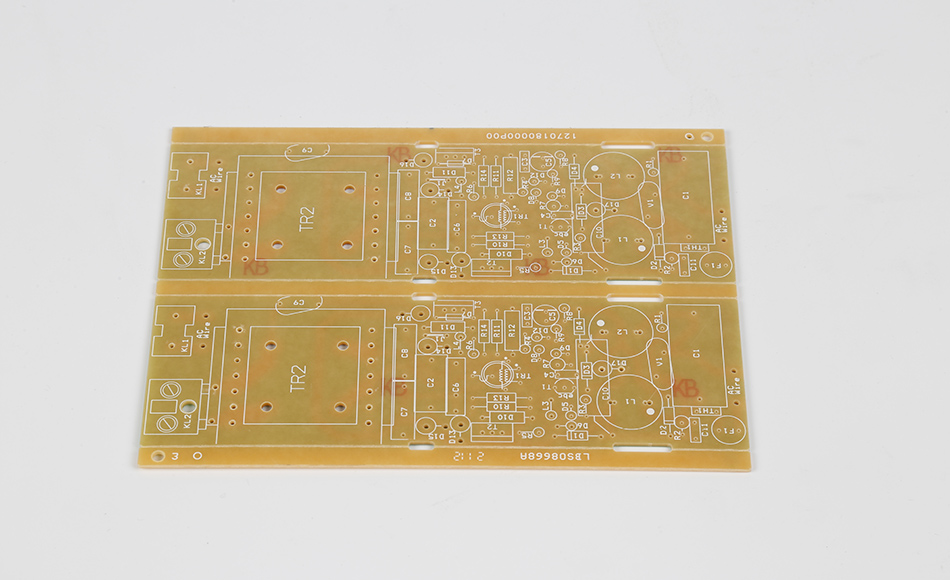

LED backlights require PCBs with precise pad placement, trace routing, and cutouts to fit edge-lit (laptops) or direct-lit (large TVs) designs. Leading suppliers align CEM3 specs with backlight architecture:

Array-Specific Pad Design: For edge-lit modules, suppliers create narrow, evenly spaced pads (matching 0.5–1mm pitch LED strips). For direct-lit modules, grid-style pads ensure consistent current across 100+ LEDs. This avoids 15–20% brightness variation from generic PCB pad misalignment.

Power Distribution Routing: Low-resistance traces prevent voltage drops (causing edge LED dimming). A 2mm-wide, 2oz copper trace reduces voltage drop by 40% vs. 1mm traces for 50-LED edge-lit modules. "Star" routing (central input with branches) ensures uniform current for direct-lit designs.

Precision Cutouts/Notches: Laser cutting (±0.1mm tolerance) creates bezel-fit cutouts (edge-lit) or thermal vents (direct-lit), cutting assembly time by 25% vs. mechanical cutting (±0.3mm tolerance).

Example: A laptop display manufacturer partnered with a supplier to design a 14-inch edge-lit PCB. Optimized 0.8mm pad spacing and 1.8mm traces reduced brightness variation from 18% to 5%, meeting premium standards.

Even low-power SMD LEDs (0.1–0.5W) generate localized heat; dense arrays (200+ LEDs in 55-inch TVs) create hot spots that degrade lifespan and cause color shift. Suppliers enhance CEM3’s thermal performance:

Thermal Pathway Enhancement: Boron nitride fillers boost in-plane conductivity by 30% vs. standard CEM3, spreading heat to PCB edges. For 55-inch direct-lit modules, this reduced LED junction temperature by 12°C, extending lifespan from 30,000 to 50,000 hours.

Double-Sided Copper Planes: 2oz–4oz copper planes (top: LED pad heat spread; bottom: heat dissipation) reduce max PCB temperature by 15% vs. single-layer copper for 200-LED arrays.

Thermal Vias: 0.3–0.5mm vias under each LED pad (high-power automotive backlights) transfer heat to the bottom plane. An automotive display module saw color shift (ΔE) drop from 3.0 to 1.5, meeting color accuracy standards.

Case Study: A TV manufacturer solved 55-inch direct-lit overheating (240 LEDs) with boron nitride fillers and 0.4mm thermal vias. LED junction temperature fell from 65°C to 52°C, and color shift stayed <ΔE 2.0 for 10,000 hours—eliminating premature failure warranties.

LED backlight manufacturers need 100,000+ PCBs/month; small property variations (thickness, copper conductivity) cause inconsistent performance. Suppliers ensure consistency via strict process control:

Material Uniformity: Fixed resin/glass fiber vendors and batch tests (Dk ±2%, thermal conductivity ±5%) avoid 8–10% Dk variation (causing 10% brightness differences) from generic suppliers.

Automated Inspection: 100% AOI (pad misalignment, trace defects) and X-ray (hidden via issues) reduce defect rates to <0.5% vs. 2–3% for manual inspection.

Lean Production: JIT lines with parallel processing (10-panel simultaneous lamination) achieve 98% on-time delivery for 200,000-unit/month TV orders vs. 90% for sequential production.

Result: A wearable manufacturer (150,000 smartwatch displays/month) used a supplier’s automated inspection and JIT production. PCB thickness (±0.05mm) and pad alignment (±0.03mm) consistency cut defect rates from 3.2% to 0.4%, saving $120,000/year in rework.

LED backlight PCBs must meet reliability, safety, and sustainability standards to avoid redesigns/recalls. Leading suppliers ensure compliance:

Reliability Standards: IEC 62368-1 (consumer displays) and AATCC 16-2004 (lightfastness, anti-yellowing); IEC 60068-2-1/-2 (automotive, -40°C to 85°C resistance).

Environmental Compliance: RoHS 2.0 (no lead/mercury), halogen-free options, and UL 94 V-0 flame retardancy (enclosed spaces like laptops).

Quality Certifications: ISO 9001 (quality), ISO 14001 (environmental), and IATF 16949 (automotive) streamline audits, cutting time-to-market by 4–6 weeks.

Example: An automotive Tier 1 supplier needed IATF 16949 and IEC 60068-2-14 (thermal shock) compliance. The supplier’s PCBs passed 1,000 -40°C to 85°C cycles with no delamination, qualifying for a global EV lineup.

Different backlight segments (consumer, automotive, wearables) have unique needs; suppliers tailor capabilities to each.

Consumer displays (TVs, laptops) demand <8% brightness variation at low cost for mass markets. Suppliers optimize:

Cost-Effective Materials: Standard CEM3 (budget TVs, minimal thermal fillers) vs. high-flatness CEM3 (Ra <0.8μm, premium laptops, <5% brightness variation).

Large-Format PCBs: 1200mm×600mm PCBs (max CEM3 size) reduce splices in 65+ inch TVs, cutting assembly time by 30% and montage - point brightness variation from 12% to 4%.

Automated Assembly Compatibility: Clear fiducial marks for pick-and-place machines reduce LED mounting time by 20% vs. poorly marked PCBs.

Automotive backlights (infotainment, HUDs) withstand harsh conditions (-40°C to 85°C, vibration, moisture) and need 10+ year lifespans. Suppliers optimize:

High-Tg CEM3: Tg >140°C retains rigidity at 105°C (under-hood modules), avoiding warping and LED misalignment.

Vibration Resistance: 4oz copper and reinforced edge plating prevent trace cracking; 0% failure after 100,000 km road tests vs. 8% for generic CEM3.

Moisture Resistance: Hydrophobic coatings reduce absorption to <1.0% (24h boiling water), preventing LED flicker in humid environments (convertible displays).

Wearables (smartwatches, fitness trackers) need ultra-thin, lightweight PCBs for compact enclosures. Suppliers optimize:

Thin-Core CEM3: 0.4–0.6mm variants (vs. standard 1.6mm) cut PCB weight by 60% while retaining >350 MPa flexural strength (withstands wrist movement).

Miniaturized Pads/Traces: 0.3mm pitch pads and 0.2mm traces enable 30mm×40mm PCBs for 1–2 inch displays, reducing module size by 40% vs. standard CEM3.

Low-Profile Finishes: OSP ( <1μm thickness) vs. HASL (5–10μm) keeps PCBs thin, critical for 8mm-thick fitness trackers.

The LED backlight industry evolves with Mini/Micro LED, sustainability, and smart displays; suppliers adapt capabilities to stay competitive.

Mini LED (0.2–1mm) and Micro LED (<0.2mm) need ultra-precise PCBs for high-density arrays (1,000+ Mini LEDs in 15-inch laptops). Suppliers respond with:

Ultra-Fine Pitch Pads: Laser drilling/etching creates 0.15–0.2mm pitch pads, ensuring LED alignment and avoiding dead pixels (critical for Micro LED).

High-Conductivity CEM3: 99.9% pure copper reduces trace resistance, preventing voltage drops across 1,000+ LED arrays for uniform brightness.

Micro-Thermal Vias: 0.2mm vias under each LED boost through-plane conductivity by 50% vs. standard vias, managing high-density heat.

Display manufacturers prioritize carbon neutrality and recyclability; suppliers align with:

Recycled Materials: 25% recycled glass fiber (end-of-life wind turbine blades) cuts carbon footprint by 20% without performance loss.

Bio-Based Resins: Plant-derived epoxy (castor oil-based) retains thermal/mechanical properties while being biodegradable.

Energy-Efficient Production: Solar-powered curing ovens reduce manufacturing energy use by 35% vs. gas-fired ovens.

Smart backlights (ambient light-adjusted displays) need PCBs with embedded sensors. Suppliers adapt by:

Embedded Sensor Pads: Pads for ambient light/proximity sensors eliminate separate sensor PCBs, reducing module size by 15%.

Flexible Circuit Compatibility: Semi-flexible CEM3 integrates with FPCs for curved displays (automotive HUDs), enabling seamless sensor-data transmission.

LED Backlight CEM3 PCB Suppliers are strategic partners, not just vendors—directly impacting backlight performance, cost, and scalability. Their specialized capabilities (custom array design, thermal optimization, mass production consistency, compliance) solve unique backlight challenges across consumer, automotive, and wearable segments.

By tailoring CEM3 to backlight needs, suppliers help manufacturers achieve uniform brightness, extend LED lifespan, and cut costs. As trends like Mini/Micro LED and sustainability reshape the industry, their adaptability (ultra-precise PCBs, eco-friendly materials) remains critical for innovation.

For display manufacturers, choosing the right supplier determines product quality, time-to-market, and competitive advantage. Top suppliers combine CEM3 technical expertise with deep backlight knowledge, delivering balanced performance, cost, and scalability.

As LED backlights evolve toward higher brightness, smaller sizes, and smarter features, specialized CEM3 PCB suppliers will grow in importance—becoming indispensable to the future of display technology.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB