-

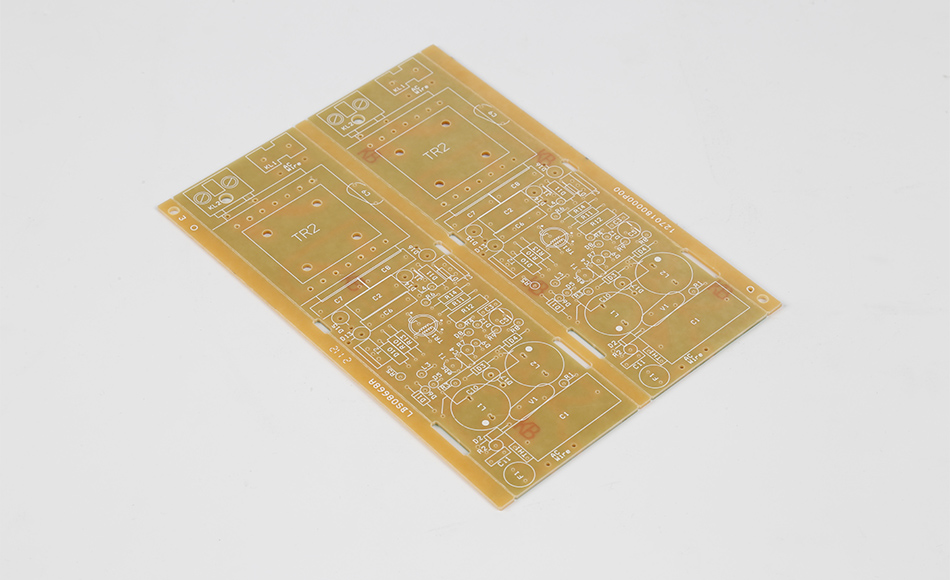

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 18. 2025, 14:57:51

The Improved Thermal Performance CEM3 Substrate marks a significant advancement in the evolution of Composite Epoxy Material-3 (CEM3), addressing a longstanding challenge: balancing the material’s inherent cost-effectiveness and mechanical stability with enhanced ability to manage heat. Unlike standard CEM3, which suffices in low-heat environments, this upgraded substrate is engineered to thrive in applications where moderate heat generation was once a limiting factor. By refining the core structure and material composition, it retains CEM3’s signature advantages—affordability, ease of manufacturing, and compliance with safety standards—while delivering meaningful improvements in thermal dissipation. This article explores the design innovations, performance metrics, application scenarios, and industry impact of the improved thermal performance CEM3 substrate, highlighting how it extends CEM3’s utility into new realms of electronics design.

Traditional CEM3 substrates have long been valued for their practicality in general-purpose electronics, but their thermal limitations restricted their use in devices with even modest heat sources. The Improved Thermal Performance CEM3 Substrate emerges from the need to expand CEM3’s capabilities without straying from its core value proposition:

Market Gap Recognition: Engineers identified that many devices—from smart home controllers to light industrial sensors—generate enough heat to stress standard CEM3 but do not require the extreme thermal resistance of high-cost alternatives like FR4 or metal-core substrates. This created a demand for a middle-ground solution.

Material Science Innovations: Advances in epoxy resin chemistry and reinforcement techniques enabled manufacturers to enhance thermal conductivity without sacrificing CEM3’s electrical insulation, mechanical strength, or flame resistance. These innovations focused on optimizing heat flow rather than overhauling the material’s fundamental structure.

Cost-Conscious Engineering: The goal was not to compete with high-thermal materials but to elevate CEM3’s performance within its existing cost bracket. This ensures the improved substrate remains accessible for mass-market applications, where price sensitivity is critical.

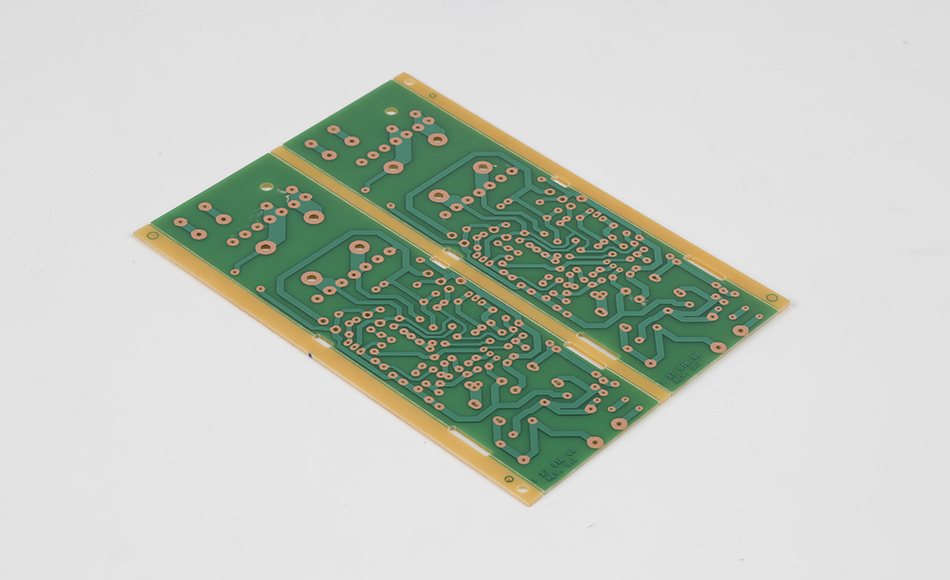

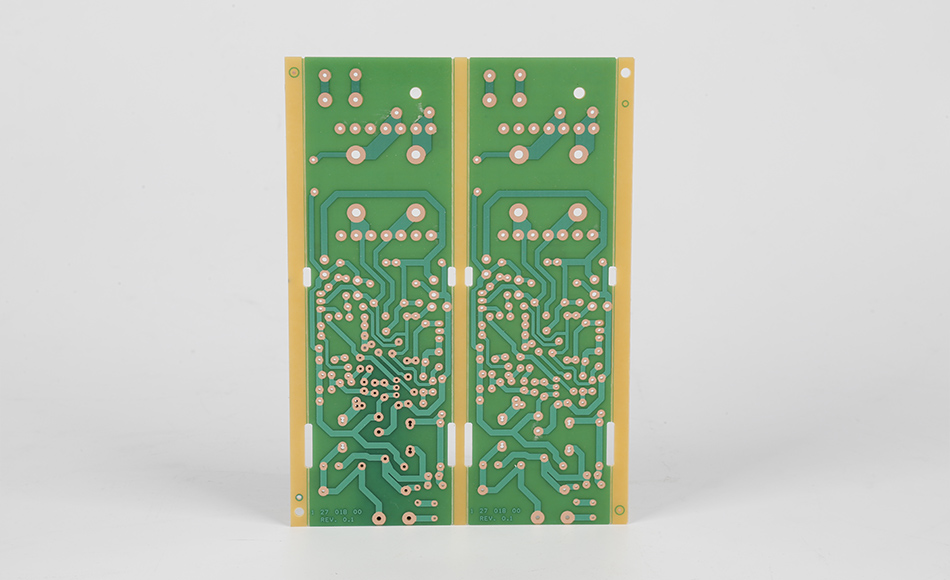

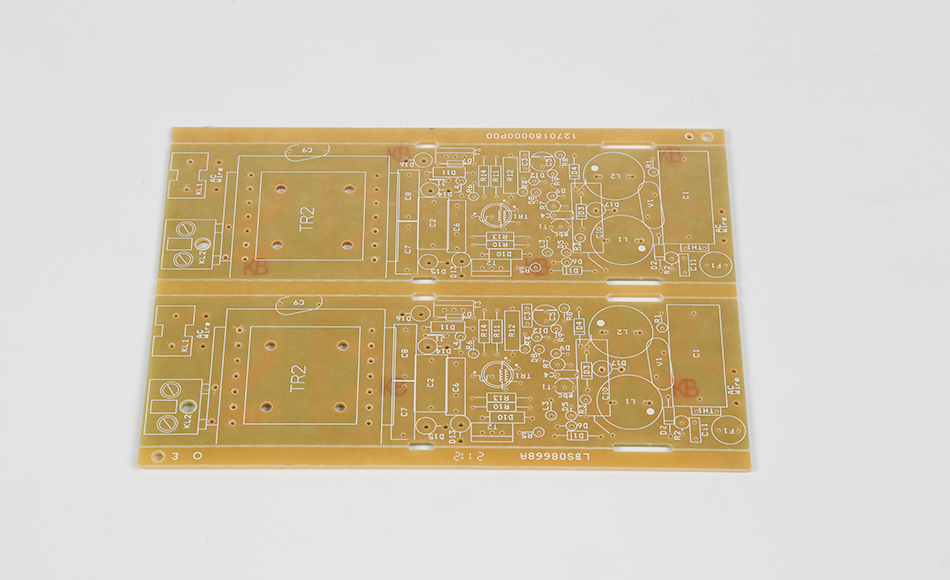

The improved thermal performance CEM3 substrate retains the classic CEM3 structure—non-woven glass core, woven glass outer layers, and epoxy matrix—but incorporates targeted modifications to boost heat management:

The epoxy resin, the primary thermal insulator in standard CEM3, is reformulated with:

Nano-Scale Additives: Microscopic particles of thermally conductive but electrically insulating materials (e.g., boron nitride platelets or aluminum oxide nanoparticles) are dispersed evenly throughout the resin. These additives create a network of thermal pathways, allowing heat to flow more freely through the matrix without compromising electrical insulation.

Modified Cure Chemistry: The resin’s curing process is adjusted to reduce void formation, as air pockets in the matrix act as thermal barriers. A more uniform cure ensures consistent heat transfer across the substrate.

The glass fiber components are tailored to support thermal performance:

Non-Woven Core Density: The non-woven glass mat’s porosity is fine-tuned to balance resin retention and thermal conduction. A slightly denser mat reduces air gaps while still allowing full resin penetration, minimizing heat trapping.

Woven Fabric Orientation: The outer woven glass layers are aligned to reduce resistance to heat moving toward the substrate’s edges, where it can be dissipated into the surrounding environment or transferred to a heat sink.

The bond between the copper cladding and epoxy matrix is strengthened to enhance thermal transfer:

Textured Copper Surfaces: Microscopic textures on the copper foil increase the surface area in contact with the resin, improving heat conduction from the copper (which spreads heat from components) to the substrate.

Adhesion Promoters: Thin layers of coupling agents are applied to the glass fibers, ensuring stronger bonding with the epoxy resin. This reduces thermal resistance at the fiber-resin interface, a common bottleneck in heat transfer.

The enhanced substrate delivers measurable benefits that expand CEM3’s application range:

Compared to standard CEM3, the improved substrate offers a 40–60% reduction in thermal resistance, meaning heat is transferred away from components more effectively. In practical terms, this translates to operating temperature reductions of 15–25°C in devices with moderate heat generation—enough to prevent thermal throttling in microcontrollers or premature failure in sensitive components like sensors.

Structural Integrity: The modifications do not compromise the substrate’s flexural strength or dimensional stability. It retains the ability to support standard components and resist warping during thermal cycling, a critical trait for reliable assembly.

Electrical Insulation: The additives used in the resin are chosen for their dielectric properties, ensuring the substrate’s insulation resistance and dielectric strength remain comparable to standard CEM3. This is essential for preventing crosstalk or short circuits in high-density designs.

Flame Resistance: The substrate maintains UL94 V-0 certification, as the thermal enhancements do not interfere with the material’s flame-retardant properties. This ensures safety in enclosed devices like consumer electronics.

The improved substrate remains cost-effective, typically adding only 15–25% to the price of standard CEM3—far less than the premium for FR4 or metal-core alternatives. It also integrates seamlessly with existing CEM3 manufacturing processes, requiring no specialized equipment or significant retooling, making it easy for manufacturers to adopt.

The substrate excels in devices where heat management is critical but extreme thermal solutions are unnecessary:

Smart Thermostats: These devices house microcontrollers and wireless modules that generate steady heat. The improved CEM3 substrate prevents overheating, ensuring accurate temperature readings and reliable connectivity.

Security Cameras: Outdoor and indoor security cameras with night vision (which uses heat-generating IR LEDs) benefit from better heat dissipation, extending operating life in enclosed housings.

Environmental Monitors: Sensors measuring temperature, humidity, or gas levels in industrial settings often operate in warm environments. The improved substrate ensures stable performance by managing both internal heat (from processing units) and external ambient heat.

Lighting Controllers: Dimmer switches and LED drivers for commercial lighting systems generate heat during operation. The enhanced thermal performance prevents overheating, ensuring consistent light output and extending controller lifespan.

Advanced Driver-Assistance Systems (ADAS) Sensors: Interior sensors (e.g., occupancy detectors or in-cabin cameras) generate heat and are often enclosed in tight spaces. The substrate’s improved heat management ensures reliable operation, even in hot vehicle cabins.

Climate Control Modules: These modules contain relays and small motors that produce heat. The substrate dissipates this heat, preventing performance issues in temperature regulation.

Fitness Trackers: Compact devices with processors and heart-rate monitors generate heat in close proximity to the body. The improved substrate helps keep surface temperatures comfortable while ensuring internal components operate within safe limits.

The improved thermal performance CEM3 substrate occupies a unique position in the market, offering a pragmatic alternative to other materials:

The improved substrate extends CEM3’s utility into heat-sensitive applications where standard CEM3 would struggle. For example, a standard CEM3 substrate in a high-power LED bulb’s driver circuit might cause the bulb to dim prematurely due to overheating, while the improved substrate maintains stable operation.

FR4 offers higher thermal resistance but at a 30–50% higher cost. The improved CEM3 substrate provides sufficient thermal performance for most consumer and light industrial applications at a lower price point, making it a better value for cost-sensitive designs.

vs. Metal-Core Substrates

Metal-core substrates (e.g., aluminum-based) excel at dissipating high heat loads but are heavier, more expensive, and require specialized manufacturing. They are ideal for high-power devices like industrial lasers, while the improved CEM3 substrate is better suited for low-to-moderate heat applications like smart home devices.

Ceramic substrates (e.g., alumina or silicon nitride) offer excellent thermal conductivity but are brittle and costly. They are reserved for extreme environments like aerospace electronics, whereas the improved CEM3 substrate provides a durable, affordable option for everyday heat management.

To maximize the benefits of the enhanced substrate, designers should consider:

Heat-generating components (e.g., power transistors, voltage regulators) should be positioned closer to the substrate’s edges to leverage the improved heat flow toward the perimeter. This minimizes hotspots in the center of the substrate, where heat can accumulate.

For devices with higher heat loads, combining the improved substrate with a small heat sink (e.g., a lightweight aluminum extrusion) at the edge of the substrate can further enhance heat dissipation. The substrate’s improved thermal conductivity ensures efficient heat transfer from the components to the heat sink.

Wider copper traces (within design constraints) can help spread heat from components more effectively, complementing the substrate’s thermal pathways. This is particularly useful for power distribution traces, which carry current and generate heat.

Manufacturers are continuing to innovate, with several trends emerging:

Research into renewable, thermally conductive additives (e.g., cellulose nanocrystals coated with ceramic) aims to reduce the substrate’s environmental impact while maintaining performance. This aligns with the growing demand for sustainable electronics materials.

Combining thermal improvements with other properties, such as enhanced moisture resistance or antimicrobial coatings, to create substrates tailored for specific environments (e.g., humid bathrooms or medical facilities).

Using computational fluid dynamics (CFD) and finite element analysis (FEA) to model heat flow in the substrate during the design phase, allowing manufacturers to optimize additive concentrations and fiber orientations for specific applications.

The Improved Thermal Performance CEM3 Substrate represents a thoughtful evolution of CEM3, addressing its thermal limitations while preserving the qualities that have made it a staple in electronics. By leveraging advanced resin chemistry, reinforcement optimization, and interface improvements, it delivers meaningful heat management benefits at an accessible price point. This substrate expands CEM3’s role into heat-sensitive applications—from smart home devices to automotive sensors—where reliability and cost-effectiveness are equally important. As electronics continue to shrink and pack more functionality into smaller spaces, the improved thermal performance CEM3 substrate will play a vital role in ensuring these devices operate safely and efficiently, proving that practical innovation can redefine the capabilities of even well-established materials.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB