-

- PCB TYPE

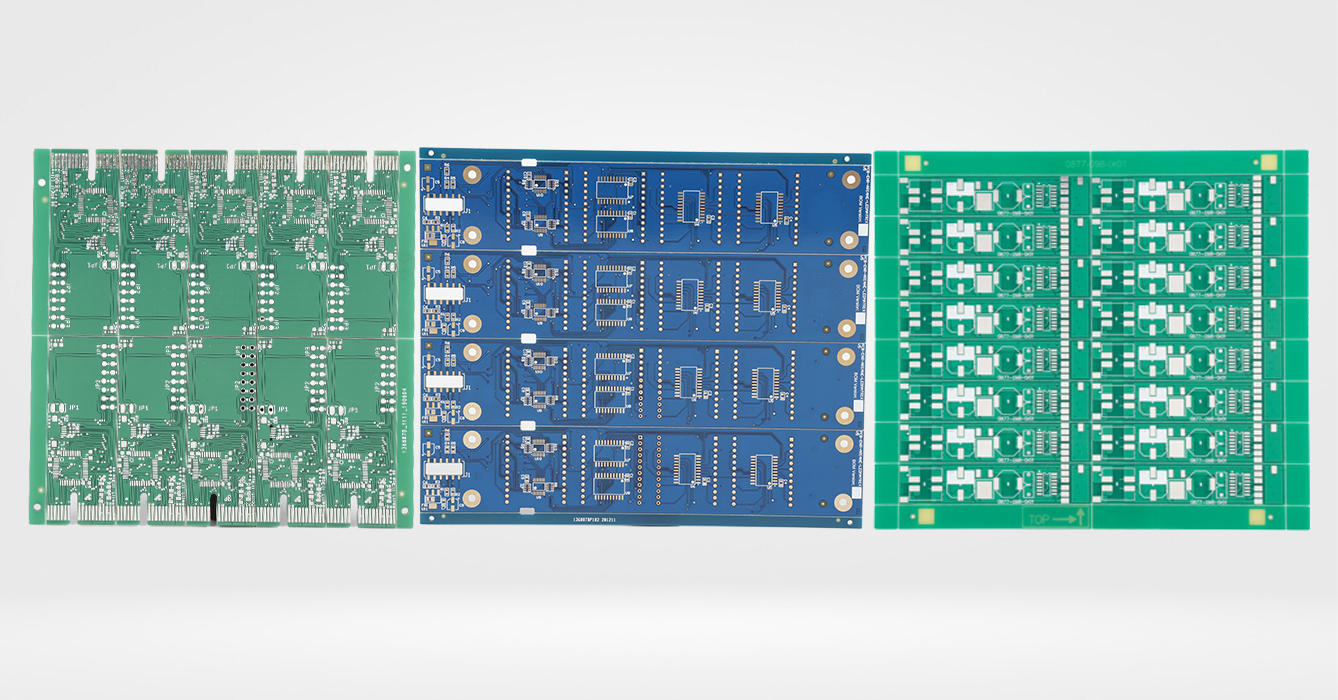

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 14. 2025, 16:43:51

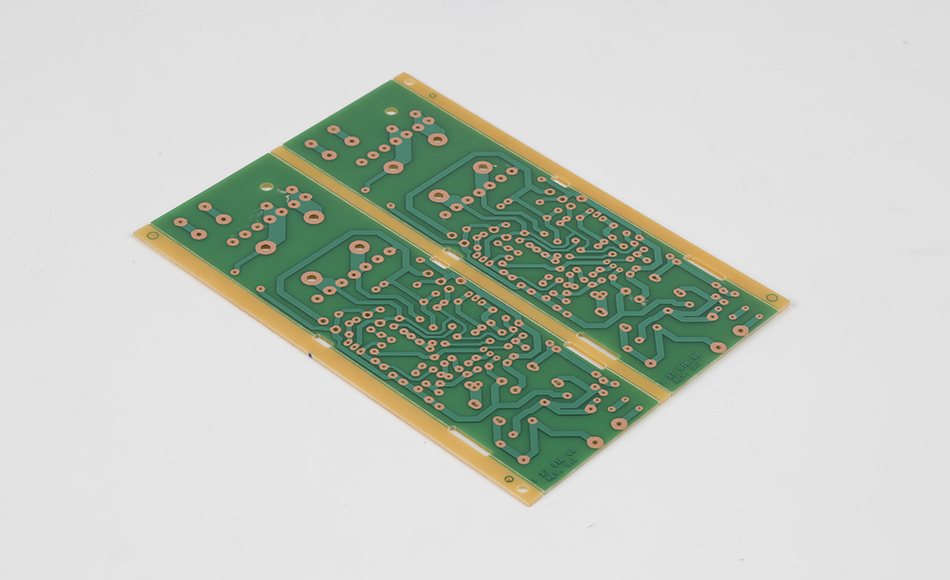

Composite Epoxy Material-3 (CEM3) stands as a cornerstone in the world of printed circuit board (PCB) substrates, valued for its unique blend of performance, affordability, and processability. As a member of the composite epoxy material (CEM) family, CEM3 occupies a critical middle ground between entry-level paper-based substrates (like CEM1) and high-performance woven glass substrates (like FR4). Its design—combining epoxy resin with a hybrid reinforcement structure—makes it ideal for a wide range of electronics, from consumer gadgets to industrial control systems, where reliability and cost-effectiveness are equally important. This article delves into the fundamental properties, structural composition, manufacturing processes, and practical applications of Composite Epoxy Material-3, highlighting why it remains a go-to choice for engineers and manufacturers seeking a balanced solution.

Composite Epoxy Material-3 is defined by its unique construction: a composite of epoxy resin reinforced with a hybrid of glass fibers. Unlike FR4, which uses woven glass fabric throughout, CEM3 features a core of non-woven glass fiber mat sandwiched between outer layers of woven glass fabric. This structure is deliberate, designed to balance mechanical stability, electrical insulation, and manufacturing ease while keeping costs lower than fully woven alternatives.

CEM3 is classified under industry standards such as IPC-4101, which specifies its key attributes: flame resistance (typically meeting UL94 V-0), dielectric properties suitable for low-to-moderate frequency applications, and sufficient mechanical strength for standard component mounting. Its epoxy resin matrix provides excellent adhesion to copper foil, ensuring reliable conductivity, while the glass fiber reinforcement prevents warping and enhances dimensional stability.

What distinguishes CEM3 from other CEM variants is its versatility. It avoids the limitations of paper-reinforced CEM1 (which struggles with moisture and heat) and the higher costs of FR4, making it a practical choice for applications that demand more than basic performance without requiring extreme durability.

The performance of Composite Epoxy Material-3 stems from its carefully engineered composition, where each component plays a specific role in balancing functionality and cost:

Epoxy Resin Matrix

At the heart of CEM3 is a thermosetting epoxy resin, chosen for its strong adhesion, electrical insulation properties, and resistance to chemicals. The resin acts as a binder, holding the reinforcement fibers together and forming a rigid, uniform substrate when cured. Unlike the specialized high-temperature epoxies used in FR4, CEM3’s resin is formulated for cost-effectiveness and ease of processing, ensuring it flows evenly during manufacturing to coat the reinforcement fibers.

Non-woven glass mat: A dense, felt-like layer of randomly oriented glass fibers forms the core. This mat absorbs resin efficiently, reducing material waste and simplifying manufacturing. Its random fiber orientation enhances resin retention and provides isotropic mechanical properties (uniform strength in all directions).

Woven glass fabric: Thin layers of woven glass fabric cover the non-woven core. Woven fabric adds directional strength, improving rigidity and resistance to tearing during handling and assembly. It also provides a smooth surface for copper cladding, ensuring consistent trace definition during etching.

This hybrid structure allows CEM3 to offer better mechanical stability than paper-based substrates while remaining more affordable than FR4, which uses woven fabric exclusively.

Thin copper foil is bonded to one or both sides of the CEM3 substrate to form conductive traces. The epoxy resin’s strong adhesion to copper ensures minimal delamination, even during thermal cycling, making CEM3 suitable for standard soldering processes. Copper thickness varies based on application needs, from thin foils for signal traces to thicker foils for power circuits.

Composite Epoxy Material-3’s popularity stems from a set of balanced properties that meet the needs of most general-purpose electronics:

CEM3’s epoxy matrix provides excellent dielectric strength, preventing current leakage between copper traces in circuits operating at up to several hundred megahertz. While not optimized for high-frequency applications (where low-dielectric materials like PTFE excel), it performs reliably in devices such as audio equipment, basic sensors, and office machines, where signal speeds are moderate.

A critical safety feature, CEM3 is formulated to be flame-retardant, meeting UL94 V-0 standards. This means it self-extinguishes quickly when exposed to fire, reducing the risk of flame spread in enclosed spaces like homes or offices. This property makes it suitable for consumer electronics and indoor industrial equipment.

The hybrid reinforcement structure gives CEM3 sufficient rigidity to support surface-mount and through-hole components without warping. While not as stiff as FR4, it resists bending and deformation during manufacturing and operation, ensuring consistent performance in standard environments. Its flexibility is also an advantage in low-volume production, where it can be easily cut or shaped to custom sizes.

CEM3 handles typical operating temperatures (ranging from -30°C to 105°C) effectively, making it suitable for electronics used in climate-controlled environments or moderate outdoor settings. It resists softening under sustained heat and maintains its bond with copper foil, though it is not designed for extreme high-temperature applications like automotive engine bays.

By using non-woven glass mat in its core, CEM3 reduces raw material costs compared to FR4, which uses more expensive woven fabric throughout. Its simplified manufacturing process—due to the non-woven core’s ability to absorb resin quickly—further lowers production expenses, making it an attractive option for cost-sensitive projects.

The production of Composite Epoxy Material-3 is designed to balance efficiency and quality, leveraging its hybrid structure to simplify key steps:

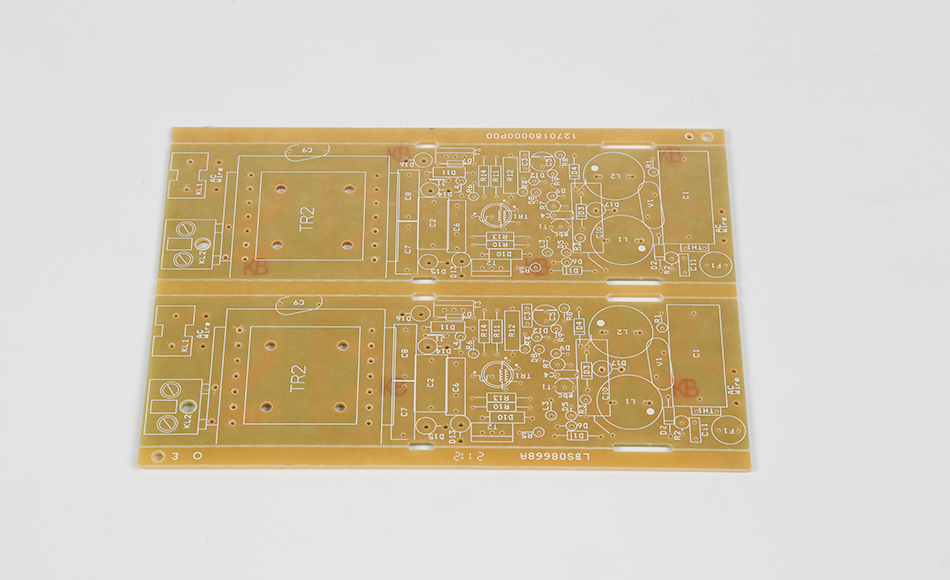

The first step involves creating prepreg—partially cured epoxy resin impregnated with glass fibers. For CEM3, this process is divided into two parts:

The non-woven glass mat core is saturated with epoxy resin, which penetrates easily due to the mat’s porous structure.

The woven glass fabric layers are separately impregnated with resin to ensure uniform coverage.

The prepreg is then partially cured (B-staged) to a tacky state, allowing it to be handled and stacked for lamination.

Layers of prepreg (non-woven core between woven fabric sheets) are stacked with copper foil and placed in a press. Heat and pressure are applied to cure the epoxy resin fully, bonding the layers into a solid laminate. CEM3 requires lower pressure than FR4 during lamination, thanks to the non-woven core’s ability to compress evenly, reducing energy consumption and equipment wear.

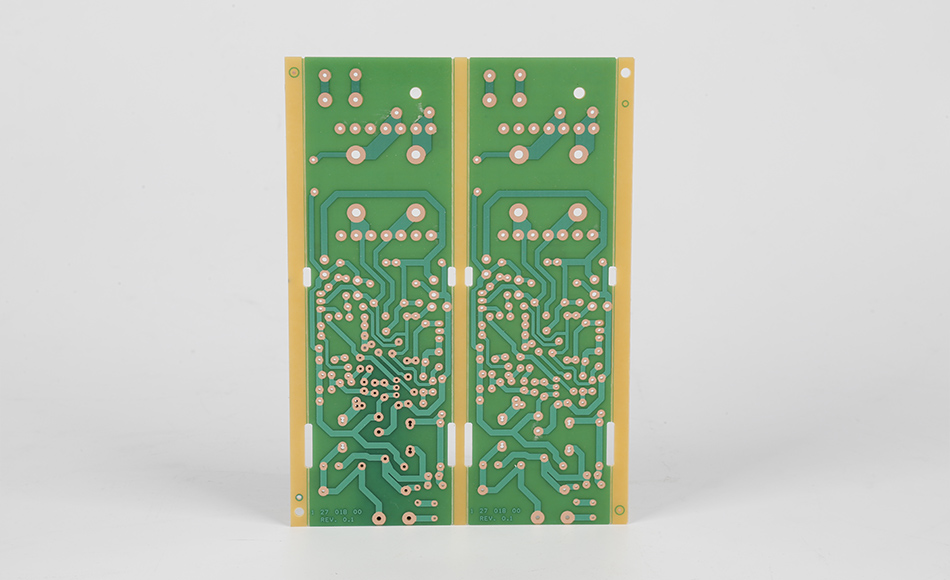

Once laminated, CEM3 sheets are cut to standard or custom sizes. Drilling holes for vias and component leads is straightforward, as the hybrid glass structure resists splintering. Standard carbide drills are sufficient, eliminating the need for specialized tools, which lowers manufacturing costs.

Copper-clad CEM3 undergoes photolithography and etching to form circuit traces, a process simplified by the material’s smooth surface. Solder mask and silkscreen are applied using standard techniques, and surface finishes like HASL (Hot Air Solder Leveling) or OSP (Organic Solderability Preservative) are added to ensure solderability and protect copper from oxidation.

This compatibility with standard PCB manufacturing processes makes CEM3 accessible to manufacturers of all sizes, from small workshops to large-scale facilities.

Composite Epoxy Material-3’s balanced properties make it suitable for a wide range of electronics, particularly those where cost and reliability are prioritized:

Devices like televisions, DVD players, and home audio systems rely on CEM3 for their main PCBs. Its affordability allows manufacturers to keep consumer prices low, while its electrical insulation and flame resistance ensure safety and performance in household settings.

Printers, scanners, and photocopiers use CEM3 for their control boards. These devices operate in stable, climate-controlled environments, where CEM3’s thermal performance and mechanical stability are sufficient. Its cost-effectiveness is also a boon for high-volume office equipment production.

Basic industrial sensors, relay modules, and simple automation controllers often use CEM3. These systems typically operate at moderate temperatures and frequencies, making CEM3’s properties a good match. Its durability is sufficient for factory floors where vibration and dust are present but not extreme.

Non-critical automotive systems, such as in-car entertainment units, window controls, and interior lighting, use CEM3. These components are shielded from extreme underhood temperatures, allowing CEM3 to perform reliably while keeping production costs down.

CEM3 is a favorite among students, hobbyists, and small-scale developers due to its low cost and ease of use. It is ideal for prototyping, robotics projects, and DIY electronics, where complex performance requirements are not a priority.

Composite Epoxy Material-3’s position in the market is defined by its balance of performance and cost, setting it apart from alternatives:

CEM1 uses paper reinforcement instead of glass, making it cheaper but less durable. It absorbs moisture easily, leading to swelling and electrical issues in humid environments. CEM3, with its glass reinforcement, offers superior moisture resistance and mechanical strength, making it suitable for more demanding applications.

FR4 uses woven glass fabric throughout, providing higher mechanical strength, thermal resistance, and signal integrity at high frequencies. However, it is 30–50% more expensive than CEM3. For applications that do not require these extreme properties—such as basic consumer electronics—CEM3 offers better value.

Older phenolic substrates are cheaper than CEM3 but lack flame resistance and have poor thermal stability. They are prone to warping and delamination, making them unsuitable for modern electronics. CEM3’s epoxy matrix and glass reinforcement make it a more reliable alternative.

Flexible PCBs (using materials like polyimide) offer bendability but are more expensive and less rigid than CEM3. They are reserved for applications requiring shape conformity, while CEM3 is preferred for rigid, cost-sensitive designs.

Composite Epoxy Material-3 is governed by industry standards that ensure consistency and reliability across manufacturers:

IPC-4101: This global standard classifies CEM3 under the “Composite Epoxy Materials” category, specifying requirements for resin content, glass fiber type, and performance metrics like dielectric strength and flexural modulus.

UL94 V-0: CEM3 must meet this flame resistance standard, ensuring it self-extinguishes within 10 seconds of ignition, with no dripping that ignites surrounding materials.

RoHS Compliance: Modern CEM3 formulations are free of hazardous substances like lead, cadmium, and hexavalent chromium, meeting Restriction of Hazardous Substances (RoHS) regulations for global markets.

IEC 60249: This standard covers base materials for PCBs, including CEM3, specifying test methods for evaluating properties like thermal endurance and chemical resistance.

Adherence to these standards ensures that CEM3 performs consistently across suppliers, giving engineers confidence in its reliability.

While CEM3 is a mature material, ongoing innovations aim to enhance its capabilities while preserving its cost advantages:

Manufacturers are developing CEM3 with bio-based epoxy resins derived from plant oils and recycled glass fibers. These formulations reduce environmental impact without compromising performance, aligning with global efforts to reduce carbon footprints in electronics manufacturing.

New epoxy additives are being tested to further reduce CEM3’s moisture absorption, extending its use to slightly more humid environments, such as outdoor lighting or coastal-area electronics.

Advancements in lamination and curing processes are making CEM3 compatible with faster production lines, reducing cycle times and making it more competitive with FR4 in high-volume manufacturing.

Composite Epoxy Material-3 (CEM3) has earned its reputation as a versatile, cost-effective substrate for a wide range of electronics, thanks to its balanced blend of mechanical stability, electrical performance, and processability. Its hybrid structure—non-woven glass core with woven glass outer layers—strikes a perfect balance between affordability and reliability, making it indispensable in consumer electronics, office equipment, and basic industrial systems. While it may not match the extreme performance of FR4 or specialized substrates, CEM3 excels in applications where cost and practicality are key. As manufacturing processes and formulations continue to evolve, CEM3 will remain a critical part of the PCB material ecosystem, enabling accessible, reliable electronics for years to come.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB