-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 18. 2025, 15:07:21

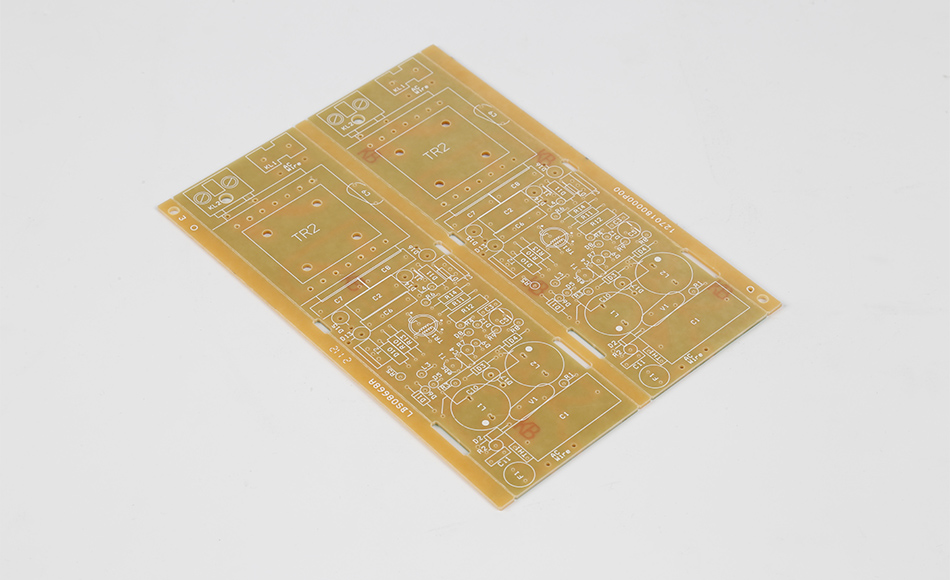

CEM3 PCB has solidified its position as a foundational element in the global electronics landscape, offering a rare combination of versatility, reliability, and cost-efficiency that few substrates can match. As a composite material derived from epoxy resins and glass fibers, CEM3 PCBs bridge the gap between entry-level paper-based substrates and high-performance alternatives like FR4, making them indispensable in applications where extreme performance is unnecessary but consistent functionality is non-negotiable. From household appliances to light industrial equipment, these PCBs serve as the backbone of devices that power daily life, proving that practical engineering often delivers the most impactful solutions. This article examines the unique role of CEM3 PCBs in the electronics ecosystem, their adaptability to evolving design demands, environmental considerations, and future prospects, highlighting why they remain a preferred choice for engineers and manufacturers worldwide.

At its core, CEM3 PCB owes its enduring popularity to a set of intrinsic qualities that align with the needs of mass-market electronics:

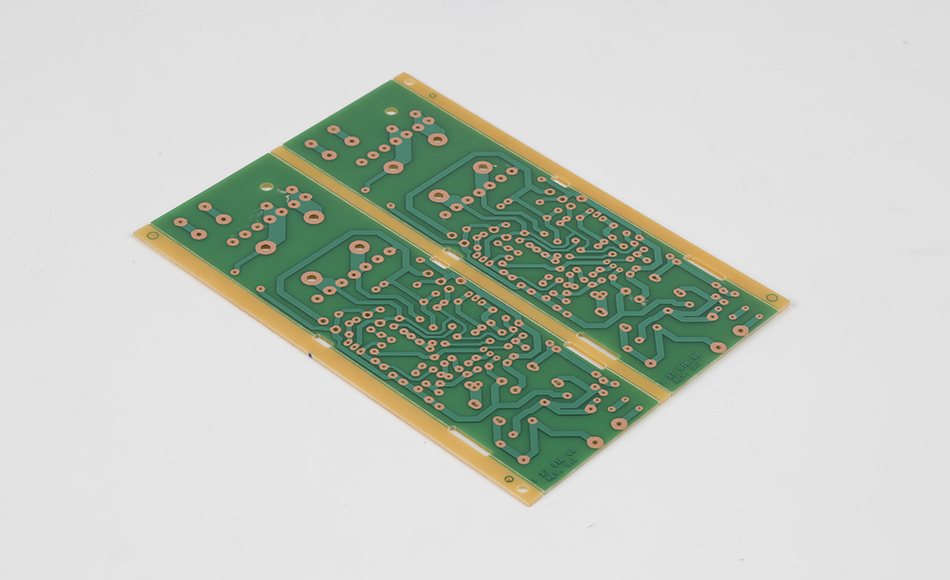

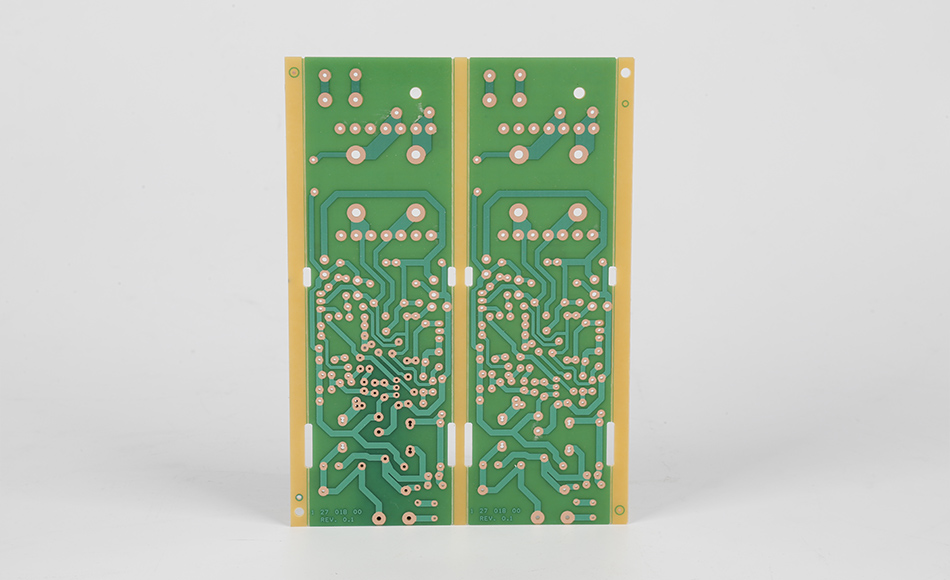

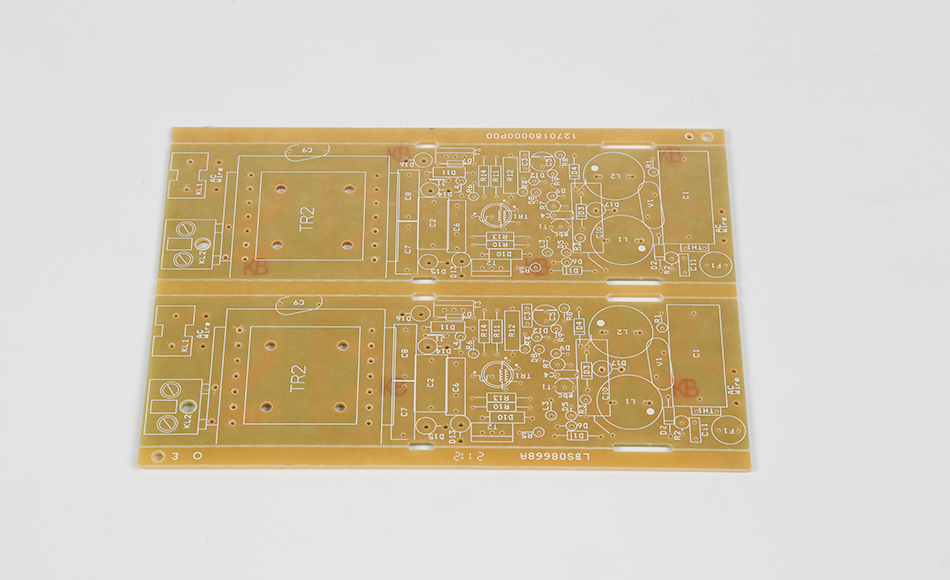

CEM3 PCBs are constructed from a hybrid structure: a non-woven glass fiber core sandwiched between woven glass fabric layers, all bonded by epoxy resin. This design imparts sufficient rigidity to support standard components while retaining a degree of flexibility that simplifies manufacturing and handling. Unlike rigid FR4, which can crack under stress, CEM3 PCBs withstand minor bending during assembly, reducing scrap rates in high-volume production. This balance makes them ideal for devices with moderate mechanical demands, such as remote controls and small appliances.

The epoxy matrix in CEM3 PCBs provides stable electrical insulation, ensuring minimal signal loss in circuits operating at frequencies up to several hundred megahertz. This performance level is perfectly suited for devices like audio equipment, basic sensors, and home automation controllers, where high-speed data transmission is not required. The material’s dielectric properties remain consistent across typical operating temperatures (-30°C to 105°C), ensuring reliable performance in indoor and light industrial environments.

By using non-woven glass fiber in its core, CEM3 reduces raw material costs compared to fully woven substrates like FR4. The manufacturing process is also simpler: the non-woven core absorbs epoxy resin more efficiently, shortening lamination times and lowering energy consumption. These savings translate to lower per-unit costs, a critical factor for consumer electronics brands competing in price-sensitive markets. For example, a manufacturer producing millions of smart bulb controllers can achieve significant cost reductions by using CEM3 PCBs instead of FR4, without compromising performance.

One of CEM3 PCB’s greatest strengths is its ability to adapt to a wide range of design specifications, making it a favorite among engineers working on varied projects:

CEM3 PCBs are produced in both standard panel sizes (e.g., 300x400mm) for high-volume applications and custom dimensions for niche devices. This flexibility allows manufacturers to optimize material usage, reducing waste in small-batch production runs. For instance, a medical device company producing a specialized heart rate monitor can order CEM3 PCBs in a compact, custom size, ensuring a perfect fit in the device’s housing without paying for excess material.

CEM3 PCBs accommodate both through-hole and surface-mount components, offering designers flexibility in part selection. Through-hole components, such as connectors and large capacitors, are securely anchored by the PCB’s rigid structure, while surface-mount devices (SMDs) adhere reliably to the smooth copper cladding. This versatility is particularly valuable in mixed-technology designs, such as industrial sensor modules that combine sensitive SMD sensors with robust through-hole power connectors.

To enhance solderability and corrosion resistance, CEM3 PCBs can be treated with a range of surface finishes:

HASL (Hot Air Solder Leveling): A cost-effective option for standard applications, providing a reliable solder joint for through-hole and SMD components.

OSP (Organic Solderability Preservative): A lead-free finish ideal for high-volume consumer electronics, ensuring long-term solderability without compromising environmental compliance.

ENIG (Electroless Nickel Immersion Gold): A durable finish for high-reliability applications, such as automotive sensors, offering excellent resistance to wear and oxidation.

This compatibility with diverse finishes allows CEM3 PCBs to meet the specific requirements of industries from consumer electronics to automotive.

As the electronics industry shifts toward sustainability, CEM3 PCB has evolved to meet eco-friendly standards without sacrificing performance:

CEM3 PCBs are available in halogen-free formulations, replacing brominated flame retardants with phosphorus or nitrogen-based alternatives. These formulations meet strict environmental regulations, including EU RoHS and China RoHS 2.0, which restrict the use of hazardous substances. Halogen-free CEM3 PCBs produce fewer toxic emissions during combustion, making them safer for both manufacturing workers and end-users.

The glass fiber and copper components of CEM3 PCBs are highly recyclable. At the end of a device’s lifecycle, recycling facilities can separate and recover these materials, reducing the environmental impact of electronic waste. Additionally, CEM3’s efficient manufacturing process generates less scrap compared to more complex substrates, aligning with circular economy principles.

The simplified lamination process for CEM3 PCBs consumes less energy than FR4 production, which requires higher temperatures and longer curing times. This lower energy footprint reduces the carbon emissions associated with manufacturing, making CEM3 a more sustainable choice for brands aiming to reduce their environmental impact.

CEM3 PCBs are integral to a wide range of devices, each leveraging their unique combination of properties:

Home Appliances: Refrigerators, microwaves, and washing machines rely on CEM3 PCBs for their control systems. These PCBs manage temperature regulation, motor operation, and user interfaces, withstanding the daily wear and tear of household use.

Personal Devices: Electric toothbrushes, portable fans, and digital scales use CEM3 PCBs for their lightweight design and energy efficiency. The material’s electrical insulation ensures safe operation in close proximity to users.

Printers and Scanners: CEM3 PCBs coordinate motor movements, sensor inputs, and data processing in these devices. Their mechanical stability resists vibrations from paper feed mechanisms, ensuring consistent performance.

POS Systems: Point-of-sale terminals use CEM3 PCBs for their durability in high-use retail environments. The material’s flame resistance adds a safety layer in busy stores where electrical equipment is in constant use.

Basic Sensors: Temperature, humidity, and motion sensors deployed in smart buildings use CEM3 PCBs for their cost-effectiveness. These PCBs process analog signals and transmit data wirelessly, operating reliably in indoor environments.

Lighting Controls: LED driver circuits in commercial lighting systems leverage CEM3’s stable electrical performance to regulate current, ensuring consistent brightness and energy efficiency.

CEM3 PCBs are widely used in in-car electronics, such as infotainment systems, window controls, and seat heaters. Their flame resistance meets automotive safety standards, while their ability to withstand temperature swings from -30°C to 85°C ensures reliability in extreme weather conditions.

CEM3 PCBs occupy a unique niche in the market, offering distinct advantages over other substrates in specific scenarios:

FR4 PCBs provide higher mechanical strength and thermal resistance, making them suitable for high-power or high-frequency applications. However, they cost 30–50% more than CEM3 PCBs, making them overkill for most consumer devices. For example, a smart speaker’s control PCB functions identically on CEM3 as on FR4, with no impact on sound quality or connectivity.

CEM1 PCBs use a paper core, making them cheaper but prone to moisture absorption and heat damage. They fail in humid environments or at temperatures above 80°C, limiting their use to low-cost, low-reliability devices like disposable electronics. CEM3’s glass reinforcement eliminates these issues, justifying its modest price premium.

Flexible PCBs (polyimide-based) excel in curved or wearable devices but are expensive and less rigid. CEM3 PCBs are better suited for flat, rigid designs, such as control panels, where their structure provides stable component mounting.

Metal-core PCBs (MCPCBs) dissipate heat effectively but are heavier and more costly. They are reserved for high-power applications like LED drivers, while CEM3 PCBs suffice for low-heat devices like remote controls.

As technology evolves, CEM3 PCBs are adapting to meet new demands, ensuring their continued relevance:

Manufacturers are developing CEM3 formulations with improved thermal conductivity by incorporating ceramic nanoparticles into the epoxy resin. These variants can handle slightly higher heat loads, expanding their use into applications like small motor controllers and LED drivers.

Research into bio-based epoxy resins, derived from plant oils or agricultural waste, is reducing CEM3’s reliance on petroleum. These sustainable formulations maintain performance while lowering the material’s carbon footprint, appealing to eco-conscious brands.

CEM3 PCBs are compatible with emerging manufacturing technologies, such as automated optical inspection (AOI) and 3D printing of solder masks. This integration reduces production errors and accelerates time-to-market for new devices, ensuring CEM3 remains a viable choice in an increasingly digitized industry.

CEM3 PCB stands as a testament to the power of practical engineering, offering a versatile, cost-effective solution that meets the needs of diverse electronics applications. Its balanced properties—mechanical stability, reliable electrical performance, and adaptability—make it a cornerstone of mass-market devices, from home appliances to industrial sensors. As the industry evolves, CEM3 PCBs continue to adapt, with innovations in sustainability and thermal performance expanding their capabilities. For engineers and manufacturers, CEM3 PCBs represent more than a substrate; they are a strategic choice that enables accessible, reliable technology without unnecessary compromise. In a market often focused on cutting-edge materials, CEM3 PCB proves that sometimes the most effective solutions are those that balance performance, cost, and versatility.

Related Articles

CEM3 PCB Material Guide for Cost-Effective Electronic Applications

High Durability Composite Epoxy CEM3 Material

Thermal CEM3: Balancing Heat Management and Practicality in Electronics Substrates

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB