-

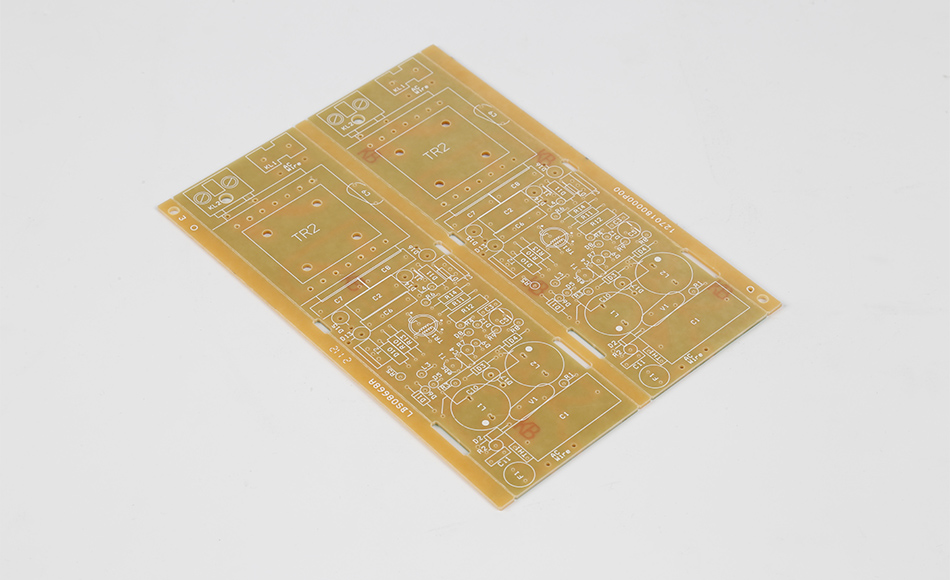

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 18. 2025, 15:02:28

Thermal CEM3 represents a specialized category of Composite Epoxy Material-3 (CEM3) substrates engineered to address the thermal challenges of modern electronics without abandoning the material’s core strengths of affordability and versatility. Unlike standard CEM3, which is designed primarily for electrical insulation and mechanical stability, thermal CEM3 focuses on enhancing heat dissipation capabilities to meet the demands of devices generating moderate levels of heat. This adaptation allows it to serve as a pragmatic solution in applications where excessive heat could compromise performance but where high-cost thermal materials (such as metal-core PCBs or ceramics) would be unnecessarily expensive. This article explores the fundamental thermal properties of thermal CEM3, its design principles, real-world applications, and how it fits into the broader landscape of thermal management materials, highlighting its unique role in balancing functionality and cost.

To appreciate the value of thermal CEM3, it is essential to first grasp how heat behaves in standard CEM3 and where its limitations lie:

Standard CEM3 relies on epoxy resin as a matrix, which is a poor thermal conductor, and glass fibers, which offer only moderate thermal transfer. Heat generated by components on the PCB tends to accumulate in localized hotspots because the material struggles to distribute it evenly or transfer it to the edges for dissipation. This is acceptable in low-power devices (e.g., simple remote controls) but becomes problematic in devices with even modest heat sources, such as small microcontrollers or LED drivers.

Thermal CEM3 is defined by improvements in two critical metrics:

Thermal Conductivity: The ability to transfer heat through the material. Thermal CEM3 enhances this through targeted modifications, allowing heat to flow more freely from hot components to cooler areas of the PCB.

Thermal Resistance: The opposition to heat flow. By reducing thermal resistance, thermal CEM3 ensures that less heat is trapped near heat sources, lowering overall operating temperatures.

These improvements are not aimed at matching the extreme performance of specialized thermal materials but rather at elevating CEM3’s capabilities to cover a broader range of applications.

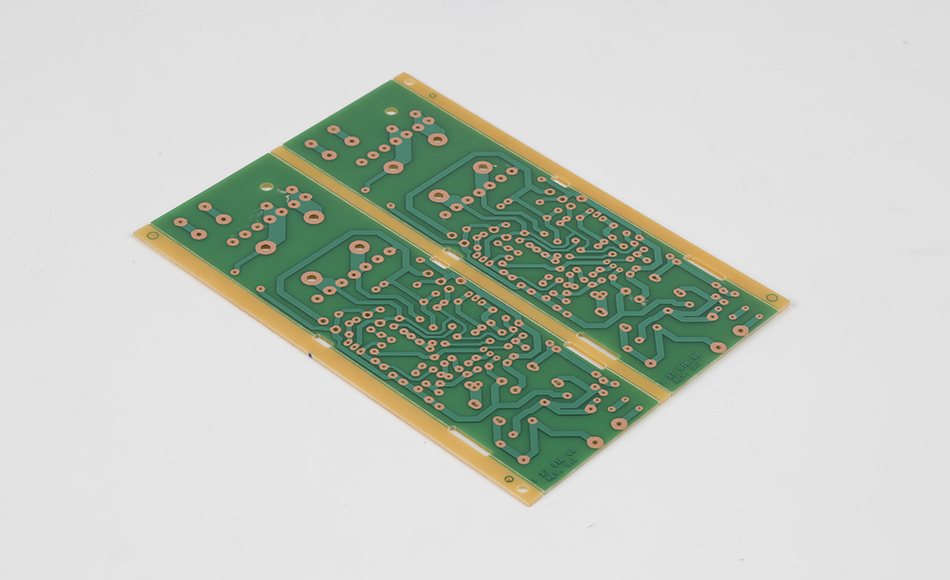

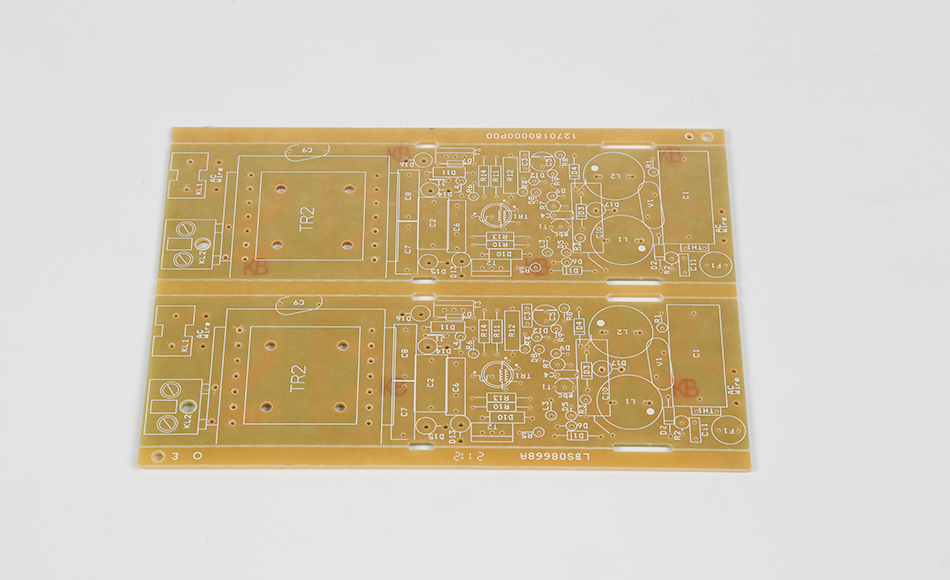

Thermal CEM3 retains the basic structure of standard CEM3—non-woven glass fiber core, woven glass fabric outer layers, and epoxy matrix—but incorporates strategic modifications to enhance thermal performance:

The epoxy resin in thermal CEM3 is reformulated to improve thermal conductivity while preserving electrical insulation:

Thermally Conductive Fillers: Microscopic additives such as aluminum oxide, boron nitride, or silicon carbide are dispersed within the resin. These fillers create a network of thermal pathways that allow heat to move through the resin more efficiently than in standard CEM3. Importantly, these fillers are electrically insulating, ensuring the material does not compromise the PCB’s electrical performance.

Resin Viscosity Adjustments: The resin’s viscosity is optimized to ensure uniform dispersion of thermal fillers, preventing agglomeration that could create uneven thermal performance or weak points in the matrix.

The glass fiber components are tailored to support rather than hinder heat transfer:

Fiber Density and Orientation: The non-woven glass core’s density is adjusted to reduce air pockets, which act as thermal insulators. The woven outer layers may also be oriented to align with common heat flow paths (e.g., toward the PCB edges), reducing resistance to heat movement.

Surface Treatment: Glass fibers in thermal CEM3 often undergo a surface treatment to improve adhesion with the modified epoxy resin. This stronger bond minimizes thermal resistance at the fiber-resin interface, a critical bottleneck in heat transfer.

The copper foil used in thermal CEM3 plays a dual role: conducting electricity and spreading heat. To maximize heat spreading:

Thicker Copper Layers: Slightly thicker copper cladding (where design constraints allow) improves the material’s ability to distribute heat from components across the PCB surface.

Textured Copper Surfaces: Microscopic textures on the copper surface increase the contact area with the epoxy resin, enhancing heat transfer from the copper to the substrate.

Thermal CEM3 offers a range of advantages that make it a compelling choice for specific applications:

By reducing hotspots and lowering operating temperatures, thermal CEM3 extends the lifespan of components. For example, in LED bulbs, excessive heat can degrade the LED chips over time, reducing brightness and longevity. Thermal CEM3 helps dissipate this heat, ensuring consistent performance for longer periods.

Thermal CEM3 typically costs 20–30% more than standard CEM3 but is significantly cheaper than metal-core PCBs (which can cost 50–100% more) or ceramic substrates (often 100–200% more expensive). This price point makes it accessible for mass-market devices where thermal management is important but budget constraints are tight.

Thermal CEM3 can be produced using existing CEM3 manufacturing equipment and processes, requiring no major retooling. This compatibility reduces barriers to adoption for manufacturers, allowing them to integrate thermal CEM3 into their production lines without significant investment.

Thermal CEM3 maintains the mechanical strength, electrical insulation, and flame resistance (UL94 V-0 certification) of standard CEM3. This ensures it can still withstand the physical stresses of manufacturing and operation, making it suitable for applications ranging from consumer electronics to light industrial equipment.

Thermal CEM3 is particularly well-suited for devices that generate moderate heat and require a balance of thermal performance and cost:

LED Lighting: Indoor LED fixtures, such as downlights and panel lights, use thermal CEM3 to manage heat from LED drivers, ensuring stable light output and preventing premature failure.

Small Appliances: Coffee makers, toasters, and air fryers incorporate thermal CEM3 in their control boards to handle heat from heating elements and small motors, ensuring reliable operation during extended use.

Security Systems: DVRs and NVRs (network video recorders) in security systems generate heat from processing video feeds.

Thermal CEM3 helps dissipate this heat, preventing overheating and ensuring continuous recording.

HVAC Controls: Thermostats and heating/cooling control modules use thermal CEM3 to manage heat from their internal processors, ensuring accurate temperature regulation.

In-Cabin Electronics: Infotainment systems, seat heaters, and climate control panels generate heat in the confined space of a vehicle cabin. Thermal CEM3 helps keep these components cool, ensuring consistent performance in varying ambient temperatures.

Sensor Modules: Proximity sensors and parking assist systems use thermal CEM3 to manage heat from their circuitry, maintaining accuracy in hot or cold weather.

Portable Medical Equipment: Devices like blood pressure monitors and pulse oximeters generate heat from their batteries and processors. Thermal CEM3 ensures these devices remain cool to the touch and function reliably during use.

Thermal CEM3 occupies a unique niche in the thermal management material landscape, offering a middle ground between standard CEM3 and specialized thermal substrates:

Thermal CEM3 outperforms standard CEM3 in heat dissipation, making it suitable for devices where standard CEM3 would allow excessive heat buildup. For example, a standard CEM3 PCB in a Wi-Fi router might overheat during heavy data transfer, causing intermittent connectivity, while thermal CEM3 would maintain stable temperatures.

FR4 offers better thermal resistance than standard CEM3 but at a higher cost. Thermal CEM3, however, often provides sufficient thermal performance for many applications at a lower price, making it a better value for cost-sensitive designs. For instance, a smart speaker’s control board would function adequately with thermal CEM3, whereas FR4 would add unnecessary expense.

MCPCBs excel at dissipating high heat loads (e.g., in industrial lasers or high-power LEDs) but are heavier and more expensive. Thermal CEM3 is a better choice for low-to-moderate heat applications, such as LED strip controllers, where MCPCBs would be overkill.

Ceramic substrates offer excellent thermal conductivity but are brittle and costly, limiting their use to extreme environments (e.g., aerospace). Thermal CEM3 provides a durable, affordable alternative for everyday applications where moderate heat management is sufficient.

To maximize the benefits of thermal CEM3, designers should consider the following guidelines:

Place heat-generating components (e.g., power transistors, voltage regulators) in areas where heat can easily spread to the PCB edges. Avoid clustering multiple heat sources in one area, as this can overwhelm the material’s thermal capabilities.

For devices with higher heat loads, pair thermal CEM3 with a small, lightweight heat sink attached to the PCB edges. This combination leverages the substrate’s improved thermal conductivity to transfer heat to the heat sink, enhancing overall dissipation.

In multi-layer thermal CEM3 PCBs, incorporate thermal vias—small holes filled with conductive material—to transfer heat from the top layer (where components are mounted) to inner layers or the bottom layer, spreading heat more evenly across the substrate.

As electronics continue to become more compact and power-dense, thermal CEM3 is evolving to meet new challenges:

Manufacturers are exploring bio-based epoxy resins and recycled thermal fillers to reduce the environmental impact of thermal CEM3, aligning with global efforts to create more sustainable electronics.

Research into new filler materials, such as graphene nanoplatelets, aims to further improve thermal conductivity without sacrificing electrical insulation or mechanical strength, expanding the material’s application range.

Thermal CEM3 is being combined with temperature sensors and adaptive cooling systems (e.g., small fans) in advanced devices, creating a dynamic thermal management solution that optimizes performance based on real-time heat levels.

Thermal CEM3 fills a critical gap in the electronics material landscape, offering enhanced heat dissipation capabilities while retaining CEM3’s signature advantages of affordability, versatility, and ease of manufacturing. By focusing on targeted modifications to epoxy resins, glass fibers, and copper cladding, it provides a practical solution for devices generating moderate heat, from LED lighting to automotive electronics. Its ability to balance thermal performance and cost makes it an invaluable material for manufacturers seeking to improve reliability without overspending. As electronics continue to evolve, thermal CEM3 is poised to play an increasingly important role in ensuring that everyday devices can handle the thermal demands of modern technology, proving that effective thermal management does not have to come at a premium.

Related Articles

CEM3 PCB Manufacturer for Cost-Effective Industrial Electronics

CEM3 PCB Material Guide for Cost-Effective Electronic Applications

High Durability Composite Epoxy CEM3 Material

CEM3 PCB: The Versatile Workhorse of Modern Electronics Ecosystem

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB