-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Sep 02. 2025, 13:24:40

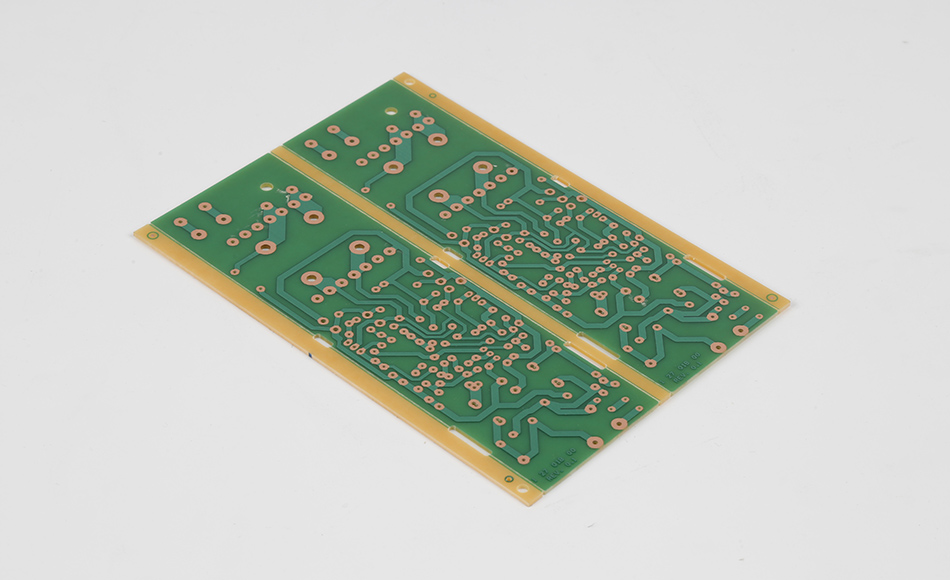

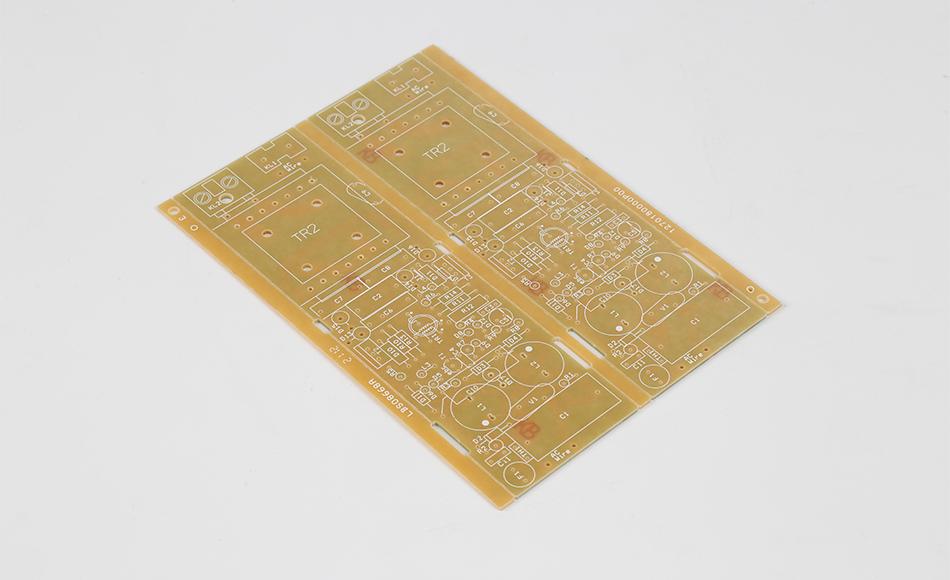

Understanding the world of printed circuit boards (PCBs) can be complex, especially when considering the various materials used in their construction. One such material that is gaining attention is the CTI 600 CEM3 PCB substrate. This article delves into the world of PCB manufacturing, focusing on the high CTI value CEM3, its significance, and how it compares to other PCB substrate types.

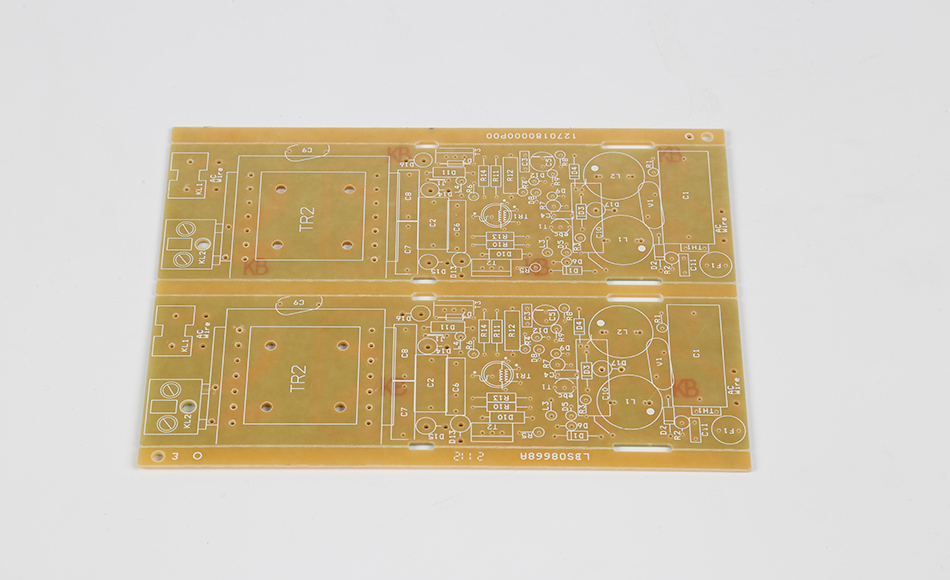

To comprehend the significance of CTI 600 CEM3, it's crucial to understand what a PCB substrate is. A substrate in PCB manufacturing is the base material that supports the layers of copper and other conductive elements. It's fundamental for ensuring electrical insulation between the conductive layers and providing mechanical support for the entire board.

Common PCB Substrate Types

There are several types of substrates used in PCB manufacturing, each offering unique characteristics:

FR-4: The most common PCB substrate, known for its good balance between performance and cost.

CEM1: A substrate type often used for single-sided PCBs.

CEM3: A glass epoxy substrate similar to FR-4 but with a white color and often used for double-sided PCBs.

CTI, or Comparative Tracking Index, is a measure of a material's resistance to electrical tracking, which is a form of electrical discharge that causes degradation of the material. The higher the CTI value, the more resistant the material is to electrical tracking. The CTI 600 CEM3 PCB substrate boasts a high CTI value, making it an excellent choice for applications where electrical stability and safety are paramount.

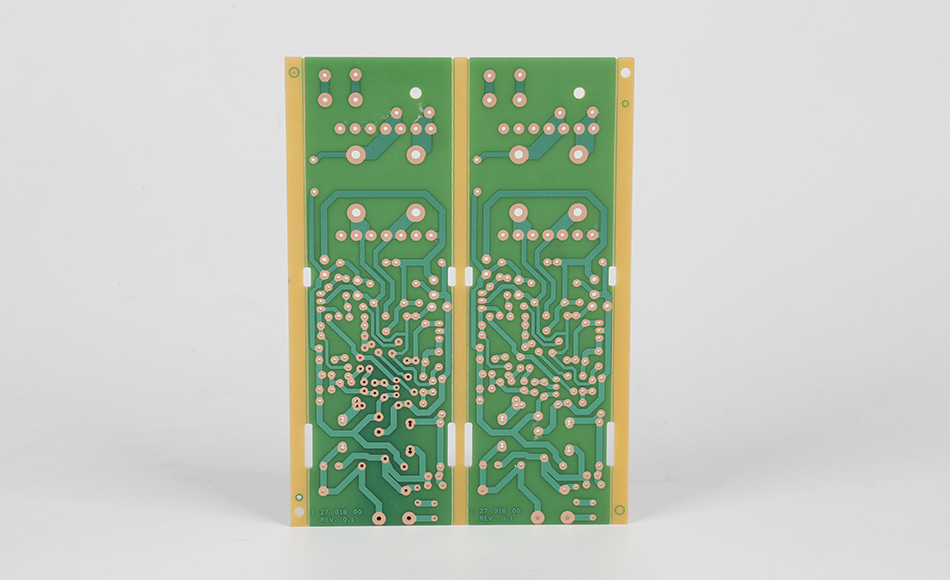

Advantages of High CTI Value CEM3

The CTI 600+ CEM3 substrate offers several advantages:

Enhanced Electrical Insulation: The high CTI value ensures better insulation, reducing the risk of short circuits.

Improved Safety: With increased resistance to electrical tracking, the substrate minimizes the risk of electrical failures.

Versatility: Suitable for various applications, from consumer electronics to industrial machinery.

CTI 600+ CEM3 vs. FR-4

FR-4 is the industry standard for PCB substrates, but how does it compare to CTI 600 CEM3?

Electrical Properties: While FR-4 is reliable, CTI 600+ CEM3 offers superior electrical insulation due to its higher CTI value.

Cost Considerations: FR-4 might be more cost-effective for standard applications, but CTI 600 CEM3 is worth the investment for projects requiring high electrical safety.

CTI 600+ CEM3 vs. CEM1

CEM1 is typically used for simpler, single-sided PCBs. Here's how it stacks up against CTI 600 CEM3:

Complexity: CEM1 is limited to single-sided designs, whereas CTI 600 CEM3 can support more complex, double-sided configurations.

Durability: CTI 600 CEM3 offers better durability and electrical performance, making it suitable for more demanding applications.

The high CTI value CEM3 is not just about safety and performance; it's also about versatility. Here are some fields where this substrate excels:

Consumer Electronics

In devices where reliability and safety are crucial, such as smartphones and home appliances, CTI 600 CEM3 ensures that the PCB can handle the electrical demands without compromising performance.

Industrial Machinery

Industrial environments are harsh, with significant electrical demands. The CTI 600+ CEM3 substrate's resistance to electrical tracking makes it a reliable choice for machinery and equipment that require robust electrical insulation.

Automotive Industry

The automotive industry demands high performance and safety. The CTI 600 CEM3 substrate meets these needs by providing the necessary electrical insulation to ensure vehicle electronics function reliably.

Selecting the appropriate PCB substrate is crucial for the success of any electronic project. Consider the following factors:

Electrical Requirements: Evaluate the electrical demands and safety requirements of your application.

Cost vs. Performance: Balance the cost of the substrate with the performance and reliability needed for your project.

Environmental Conditions: Consider the environmental conditions the PCB will face, such as temperature and humidity.

The CTI 600+ CEM3 PCB substrate is a significant advancement in PCB manufacturing, offering superior electrical insulation and safety. Its high CTI value makes it suitable for a wide range of applications, from consumer electronics to industrial and automotive industries. By understanding the benefits and applications of CTI 600 CEM3, you can make informed decisions about the best substrate for your electronic projects.

In a world where electrical safety and performance are paramount, choosing the right PCB substrate can make all the difference. CTI 600 CEM3 stands out as a reliable, versatile option for those looking to enhance the safety and efficiency of their electronic devices. Whether you're designing cutting-edge consumer electronics or robust industrial equipment, consider the advantages of CTI 600 CEM3 for your next project.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB