-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Sep 02. 2025, 13:15:14

In the world of electrical and electronic applications, choosing the right materials is crucial for safety, efficiency, and durability. One such essential material is CEM3, known for its impressive electrical properties. This article delves into the specifics of high CTI CEM3 material with a 600V rating, exploring its characteristics, benefits, and applications.

Before discussing CEM3, it is important to understand the concept of CTI, or Comparative Tracking Index. CTI is a measure of a material's ability to resist electrical tracking, which can lead to failure in insulating materials. A

higher CTI rating indicates better resistance to electrical breakdown, making materials safer for use in high-voltage environments.

Why CTI Matters

CTI is crucial because it directly affects the safety and performance of electrical devices. Materials with a low CTI can degrade quickly under high voltage, leading to short circuits or even fires. Therefore, selecting a material with a high CTI is essential, especially in applications where reliability is non-negotiable.

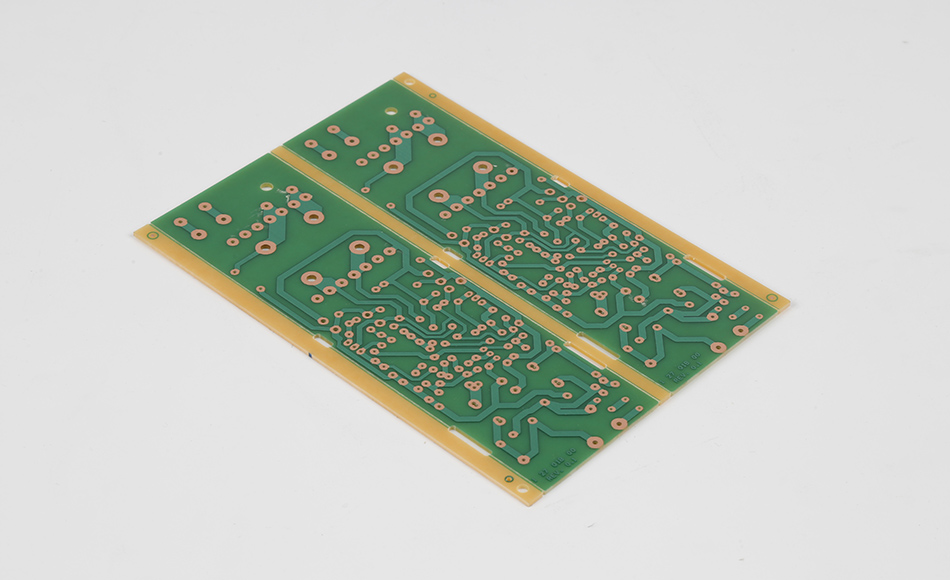

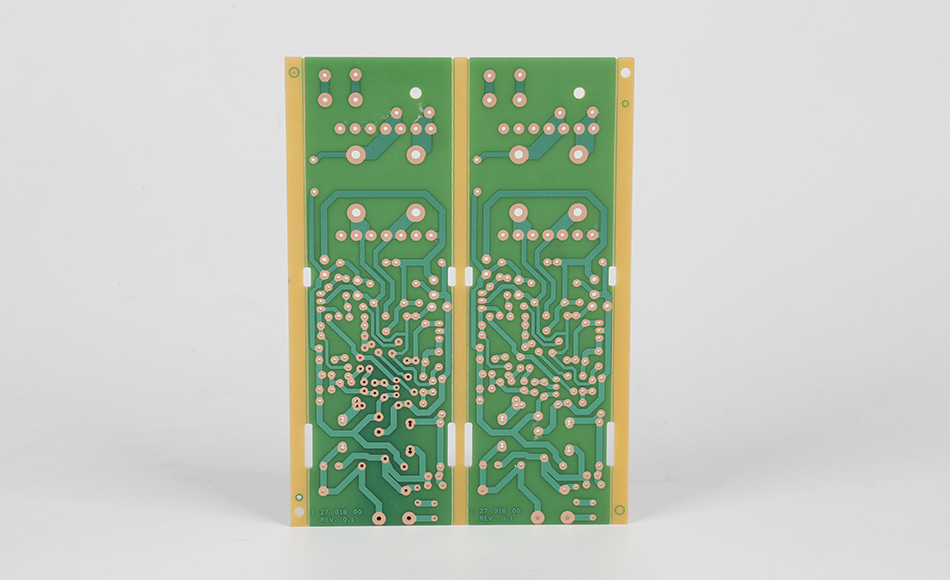

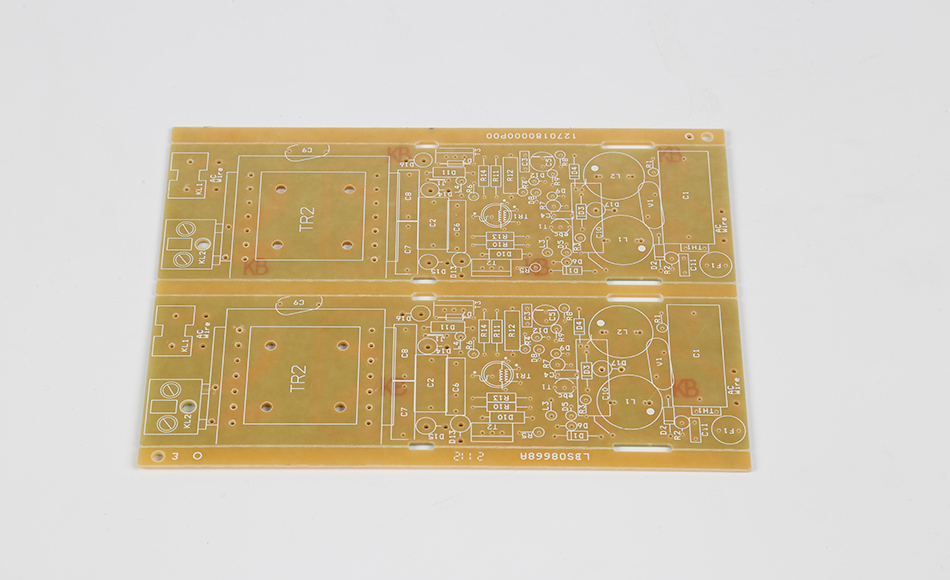

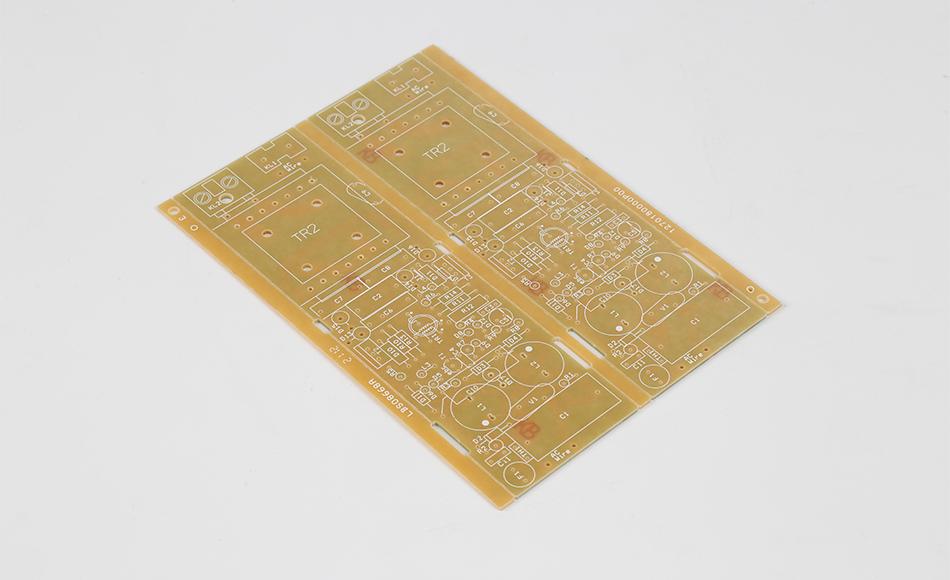

CEM3 is a type of composite material widely used in the manufacturing of printed circuit boards (PCBs). It is similar to FR-4, another popular PCB material, but offers distinct advantages that make it suitable for specific applications.

Composition of CEM3

CEM3 is composed of woven glass fabric surfaces and a paper core combined with epoxy resin. This composition gives it unique properties, such as lower density compared to FR-4, and makes it an excellent choice for applications requiring lightweight materials.

One of the standout features of CEM3 is its high CTI value. This makes it particularly suitable for high-voltage applications. The high CTI value ensures that CEM3 can withstand higher voltages without degrading, thus enhancing the safety and longevity of the devices it is used in.

Enhanced Safety: High CTI CEM3 reduces the risk of electrical failures, providing a safer operational environment.

Durability: Materials with high CTI are less likely to suffer from electrical tracking, increasing the lifespan of electrical components.

Cost-Effectiveness: While initially more expensive, the longevity and reliability of high CTI CEM3 can lead to cost savings over time by reducing maintenance and replacement needs.

In the electronics industry, high CTI CEM3 is used to manufacture printed circuit boards (PCBs) where high voltage endurance is critical. These PCBs are used in devices ranging from consumer electronics to industrial machinery.

The automotive industry benefits from high CTI CEM3 in the production of parts that require robust electrical insulation. This includes components like control units and various sensors that must operate reliably under challenging conditions.

In renewable energy systems, such as solar panels and wind turbines, high CTI CEM3 materials are used to ensure long-term reliability and safety in high-voltage applications.

While CEM3 is similar to FR-4 in many respects, its high CTI value offers distinct advantages in certain applications.

CEM3 vs. FR-4

Density: CEM3 is less dense than FR-4, making it lighter and suitable for applications where weight is a concern.

CTI Rating: CEM3 generally has a higher CTI rating than FR-4, providing better performance in high-voltage environments.

CEM3 vs. Other Composite Materials

Cost: CEM3 can be more cost-effective over its lifecycle compared to some other high-performance materials due to its durability and high CTI rating.

Versatility: CEM3 can be used in a wide range of applications, from simple consumer electronics to complex industrial systems.

Choosing the right material for your application involves considering several factors, including CTI rating, environmental conditions, and cost. High CTI CEM3 is an excellent choice for applications where safety, reliability, and efficiency are priorities.

Key Considerations

Voltage Requirements: Ensure the material can handle the maximum voltage of your application.

Environmental Factors: Consider the operating environment's temperature, humidity, and potential chemical exposure.

Regulatory Compliance: Ensure the material meets industry standards and regulations.

High CTI CEM3 material with a 600V rating is a superior choice for many electrical and electronic applications. Its high CTI rating ensures safety and reliability, making it ideal for use in high-voltage environments. Whether in the automotive industry, renewable energy, or electronic device manufacturing, CEM3 offers a combination of durability, efficiency, and cost-effectiveness that is hard to beat. When selecting materials for your next project, consider the many benefits of high CTI CEM3 to ensure success and longevity.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB