-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Nov 10. 2025, 15:34:38

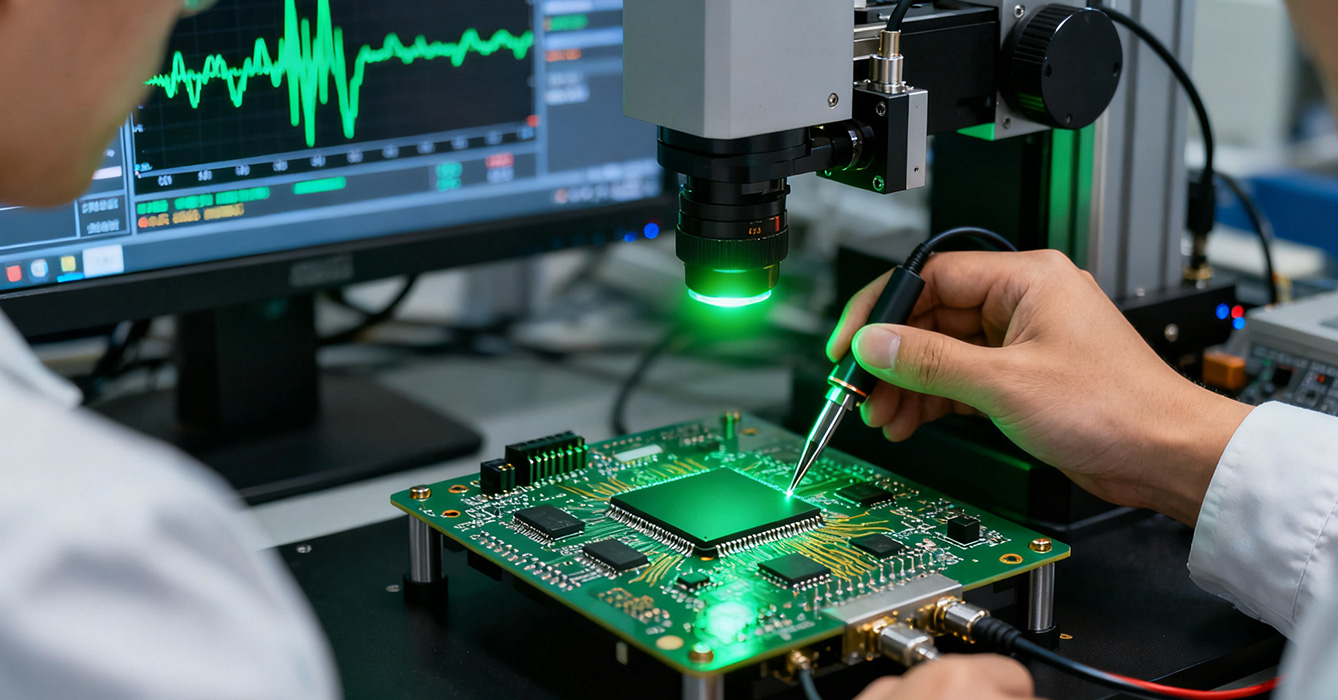

China PCB Assembly has evolved from a global manufacturing workhorse to a catalyst for technological innovation, leveraging advanced engineering capabilities and agile market responsiveness to serve the world’s most demanding electronics sectors. Beyond scale and cost efficiency, Chinese PCB assemblers now lead in developing solutions for complex, high-performance applications—from 5G base stations and autonomous vehicles to medical imaging devices. Their unique strength lies in end-to-end innovation integration: combining cutting-edge assembly technologies, close collaboration with chip designers, and flexible production models to turn emerging tech concepts into mass-produced realities. As global industries race toward digital transformation and smartification, China PCB Assembly has become a strategic partner for businesses seeking to stay at the forefront of innovation. This article explores its technical breakthroughs, green manufacturing转型 (transformation), global market alignment, and role in powering next-generation electronics.

Top Chinese PCB assemblers have invested heavily in R&D to master complex assembly challenges, setting new industry benchmarks:

- Advanced Packaging Integration: Leading assemblers specialize in heterogeneous integration (HI) and system-in-package (SiP) assembly, enabling the combination of multiple chips (e.g., CPU, GPU, memory) into compact, high-performance modules. This capability is critical for 5G chipsets and AI accelerators, where space and signal integrity are paramount.

- HDI & Flexible PCB Expertise: They excel in assembling high-density interconnect (HDI) PCBs with up to 20 layers and microvias as small as 60 microns, supporting miniaturized wearables and IoT sensors. Flexible PCB assembly, including rigid-flex designs, meets the demands of foldable devices and automotive interior electronics that require bendable circuitry.

- AI-Driven Process Optimization: Machine learning algorithms are integrated into every assembly stage—from solder paste inspection (SPI) that predicts defects to reflow oven temperature profiling that adapts to component types. This AI integration reduces process variation by 30% and improves first-pass yield to over 98% for complex boards.

China PCB Assembly is undergoing a comprehensive green transformation to meet strict global environmental standards:

Assemblers have adopted lead-free and halogen-free processes across all production lines, with advanced wastewater treatment systems that recycle over 90% of process water. Energy-efficient SMT equipment and solar-powered factories further reduce carbon footprints, aligning with EU’s Carbon Border Adjustment Mechanism (CBAM) and clients’ ESG targets.

Closed-loop recycling programs recover precious metals (gold, palladium) from defective PCBs with 95% purity, while scrap solder is reprocessed into new paste. Some assemblers also offer "take-back" services for end-of-life PCBs, disassembling and reusing functional components to minimize electronic waste.

Chinese PCB assemblers tailor their capabilities to the unique needs of global high-tech industries:

They specialize in automotive-grade PCB assembly, meeting IATF 16949 standards and supporting ADAS (advanced driver-assistance systems) with high-reliability solder joints and thermal management solutions. Assemblies for EV powertrains and battery management systems (BMS) undergo rigorous vibration and temperature cycling tests to ensure durability.

For medical imaging equipment (MRI, CT scanners) and diagnostic devices, assemblers maintain Class 8 cleanrooms and adhere to ISO 13485. They use biocompatible materials and implement strict traceability, ensuring every component can be tracked from sourcing to assembly—critical for regulatory compliance.

Qualified assemblers produce PCBs for satellite communication systems and avionics, meeting MIL-STD-883 and AS9100 standards. These assemblies feature radiation-hardened components and hermetic packaging to withstand extreme space and airborne conditions.

The industry is poised for further innovation with two key trends:

- Digital Twin-Driven Production: Virtual replicas of assembly lines will enable real-time simulation of new product introductions (NPIs), cutting time-to-market by 40% for complex designs.

- Smart Supply Chain Networks: Blockchain technology will enhance component traceability, while IoT-enabled logistics will provide end-to-end visibility of PCB shipments—reducing lead time variability for global clients.

China PCB Assembly has transcended its traditional role to become a global leader in innovation-driven electronics manufacturing. By mastering advanced assembly technologies, embracing green practices, and aligning with high-tech industry needs, it empowers businesses to turn transformative ideas into tangible products. As the world moves toward smarter, more sustainable electronics, China PCB Assembly will remain at the forefront—driving progress through technical excellence and market agility. For global innovators, partnering with Chinese PCB assemblers is no longer just about production; it’s about accessing the expertise needed to shape the future of technology.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB