-

- PCB TYPE

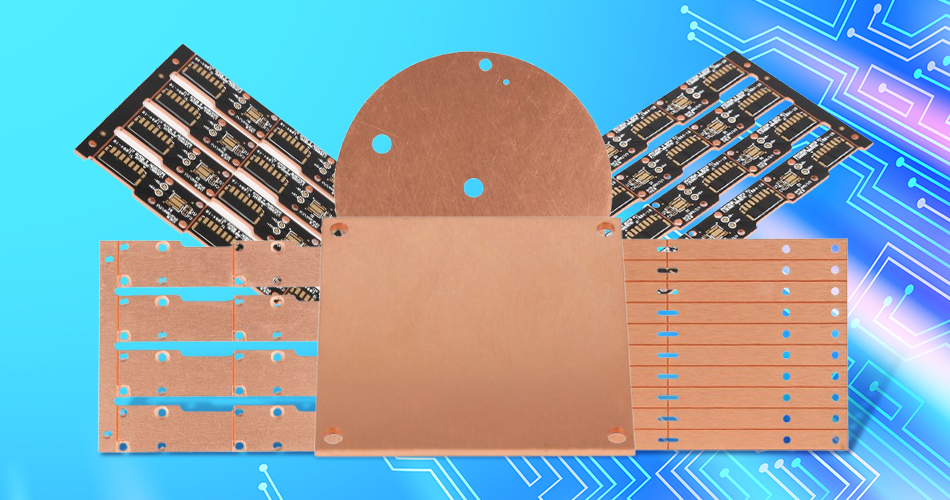

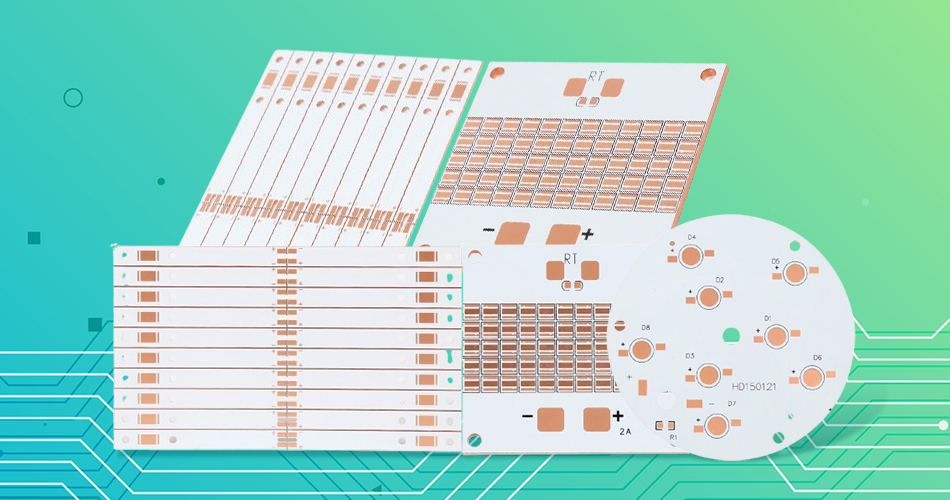

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Nov 11. 2025, 13:29:02

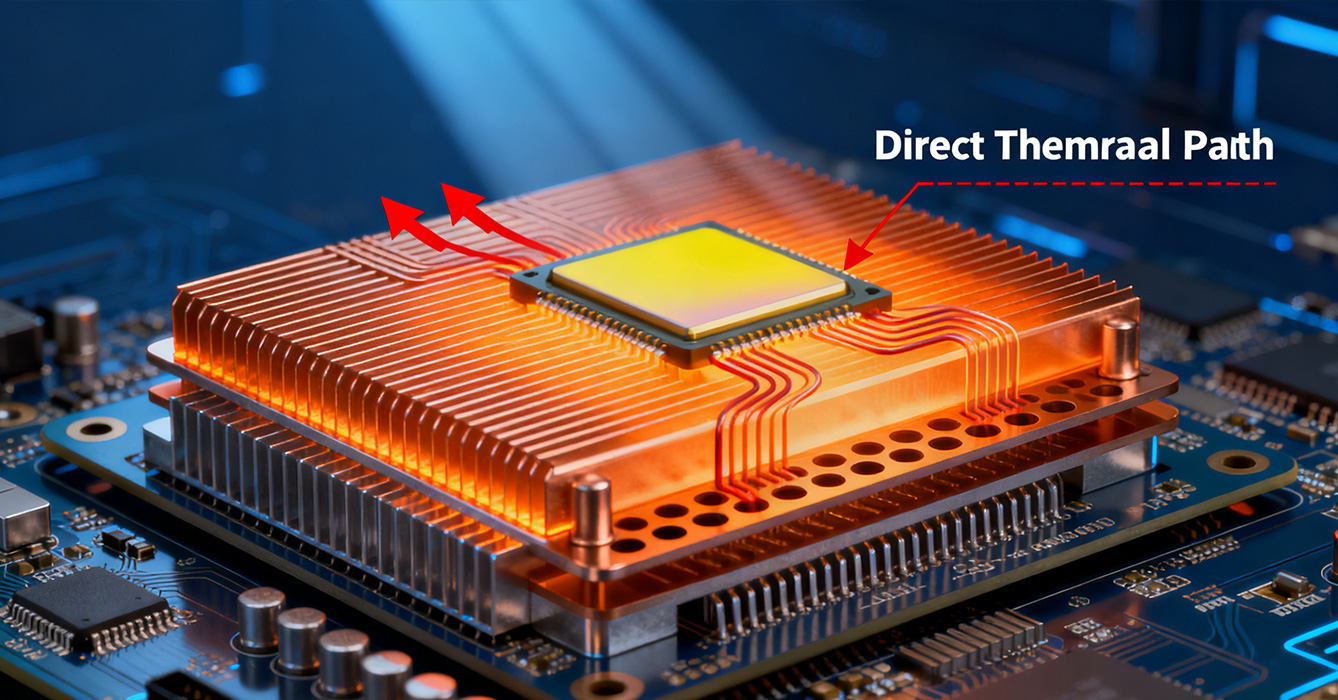

Direct Thermal Path PCB Design is a specialized approach to printed circuit board engineering that prioritizes unobstructed heat transfer from high-power components to cooling solutions—addressing a critical pain point in modern electronics. As devices grow more compact and power-dense (e.g., EV powertrains, industrial inverters, and high-performance computing modules), excess heat becomes a major threat to reliability, performance, and lifespan. Unlike conventional PCB design, which treats thermal management as an afterthought, this method integrates heat dissipation into the core layout strategy: creating direct, low-resistance paths for heat to flow from component pads to heatsinks, thermal planes, or external cooling systems. By minimizing thermal resistance and eliminating heat traps, Direct Thermal Path PCB Design ensures consistent performance even under extreme operating conditions. This article explores its core design principles, key implementation techniques, industry-specific applications, and emerging innovations shaping its future.

Successful thermal path design hinges on three foundational principles that guide layout and material choices:

The primary goal is to reduce resistance along the heat flow path. This means shortening the distance between high-power components (e.g., voltage regulators, power transistors) and cooling destinations. For example, placing a power IC directly above a thermal via array eliminates indirect heat spread through copper traces, cutting resistance by up to 40% compared to traditional layouts.

Increasing the surface area available for heat transfer amplifies cooling efficiency. Designers integrate large copper planes (top, bottom, or inner layers) as thermal reservoirs, with strategic openings to avoid signal interference. These planes act as heat spreaders, distributing concentrated heat from components across a wider area before it reaches cooling solutions.

Material selection is critical for optimizing heat flow. High-thermal-conductivity substrates (e.g., aluminum-backed PCBs, ceramic-filled laminates) replace standard FR-4 in power-dense applications, as they conduct heat up to 10x faster. Component pads are also optimized—using thicker copper (2–4 oz) to enhance heat absorption and transfer without compromising electrical performance.

Direct Thermal Path PCB Design leverages targeted engineering techniques to turn principles into practical solutions:

- Thermal Vias: Dense arrays of plated through-holes (PTHs) connect component pads directly to inner or bottom thermal planes. These vias act as "heat pipes" through the PCB, bypassing insulating layers to transfer heat rapidly.

- Thermal Relief Pads: Designed to balance heat transfer and solderability, these pads feature controlled copper connections to thermal planes—ensuring components solder properly while still allowing heat to flow freely.

- Solid Copper Pours: Unbroken copper areas beneath high-power components maximize heat absorption, while connecting to cooling systems via thermal vias.

- Partitioned Thermal Planes: For mixed-power PCBs (combining high-power and low-signal components), separate thermal planes prevent heat from high-power sections from interfering with sensitive circuitry—maintaining signal integrity while optimizing cooling.

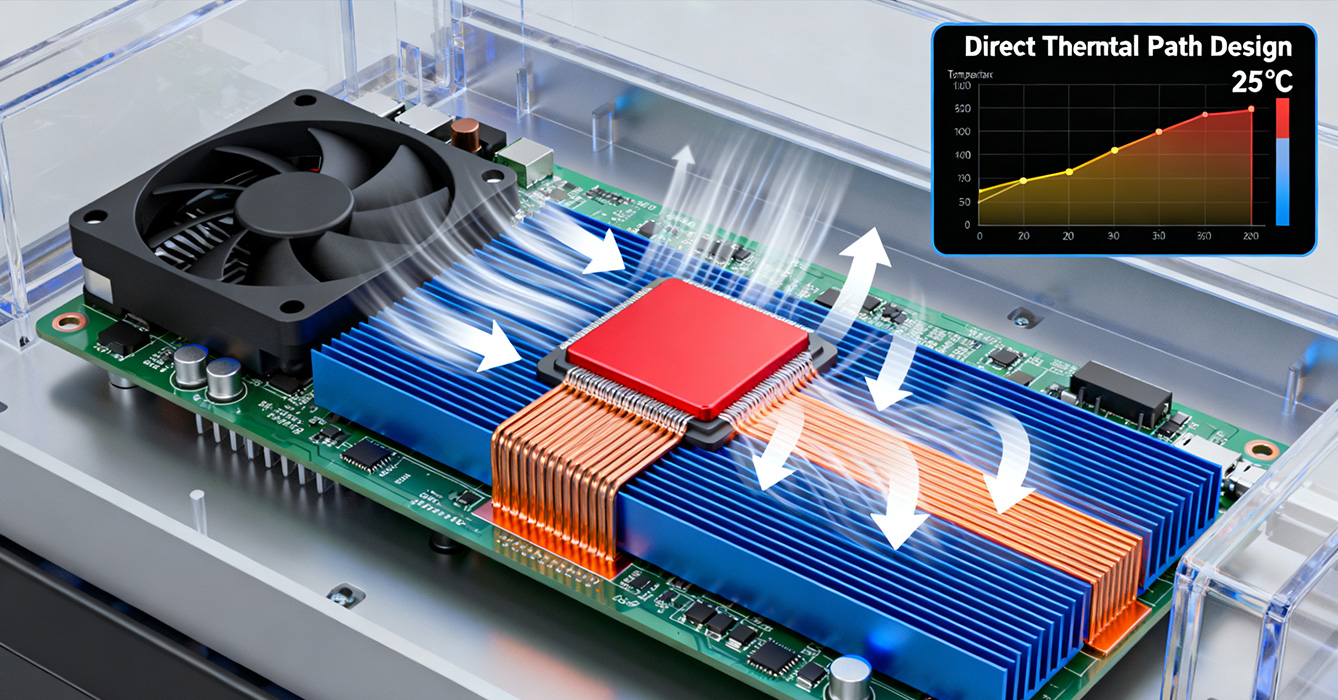

Advanced designs integrate passive cooling directly into the PCB:

- Embedded Heat Sinks: Thin aluminum or copper heat sinks are bonded to the PCB’s thermal plane, extending heat dissipation beyond the board itself.

- Thermal Breakouts: Notches or cutouts in the PCB allow high-power components to interface directly with external heatsinks or liquid cooling loops, eliminating thermal resistance from intermediate layers.

Direct Thermal Path PCB Design is indispensable for power-dense sectors:

EV battery management systems (BMS) and traction inverters rely on this design to handle high currents and heat generation. Thermal via arrays beneath power MOSFETs and IGBTs transfer heat to aluminum cooling plates, preventing overheating during fast charging or high-speed driving.

Industrial inverters, motor drives, and power supplies use direct thermal paths to withstand continuous operation in high-temperature factory environments. Ceramic substrates with integrated copper paths ensure heat is routed away from control circuitry, reducing downtime from thermal failures.

High-power LED modules (e.g., automotive headlights, industrial fixtures) use aluminum-backed PCBs with direct thermal paths. Heat from LEDs flows through copper pads and thermal vias to the aluminum base, maintaining brightness and extending LED lifespan by preventing thermal degradation.

The field is evolving to meet growing power density demands:

- AI-Driven Thermal Simulation: Machine learning tools predict heat flow during early design stages, optimizing via placement and copper pour patterns to minimize resistance—reducing prototype iterations by 50%.

- Advanced Composite Substrates: Graphene-reinforced laminates offer 5x higher thermal conductivity than FR-4, enabling thinner, lighter PCBs with superior heat dissipation.

- Modular Thermal Design: Pre-engineered thermal modules (e.g., standardized via arrays, removable heat sinks) simplify design for high-volume production, accelerating time-to-market.

Direct Thermal Path PCB Design is a game-changer for high-power electronics, turning thermal management from a reactive fix into a proactive design strategy. By focusing on minimal resistance, maximum heat spread, and compatible materials, it ensures devices perform reliably even in the most demanding conditions. As electronics continue to grow more compact and power-dense, this specialized design approach will remain essential—enabling innovations in EVs, industrial automation, and beyond. For engineers and manufacturers, mastering Direct Thermal Path PCB Design is key to delivering products that balance performance, durability, and efficiency.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB