-

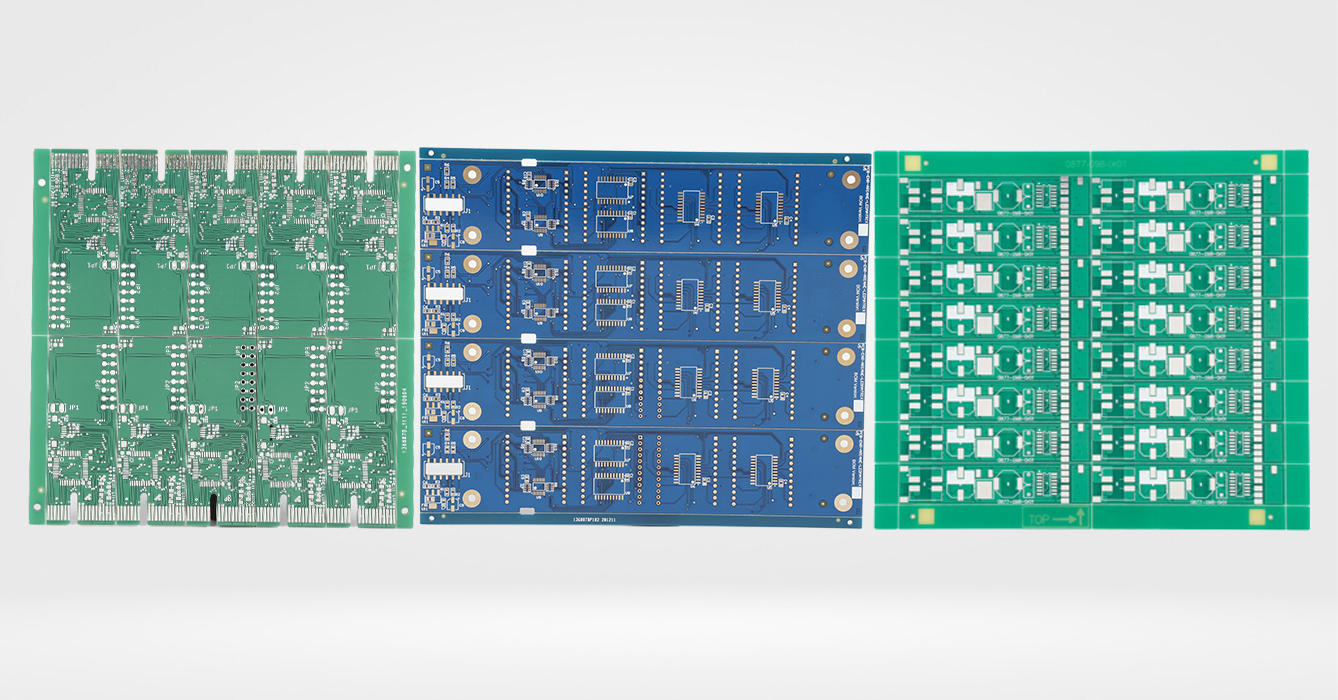

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 14. 2025, 16:36:09

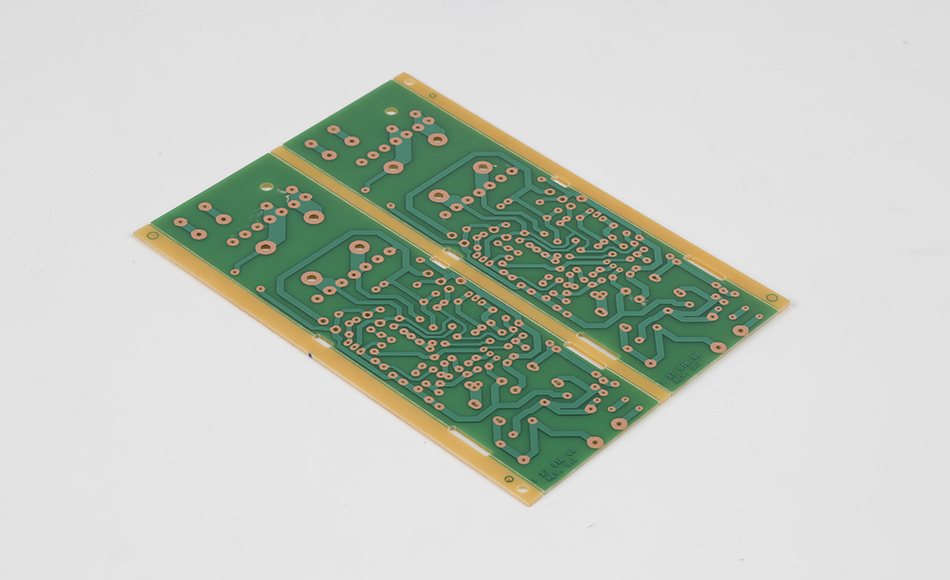

In the realm of printed circuit board (PCB) materials, High Durability Composite Epoxy CEM3 Material represents a specialized evolution of the standard CEM3 substrate, engineered to deliver enhanced resilience without sacrificing the cost-effectiveness that defines the CEM family. While traditional CEM3 excels in balancing performance and affordability for general applications, high durability variants are tailored for environments where longevity, resistance to harsh conditions, and sustained reliability are critical. This material bridges the gap between standard CEM3 and higher-cost substrates like FR4, offering a targeted solution for electronics exposed to temperature fluctuations, mechanical stress, or chemical exposure. This article explores the unique properties, formulation advancements, manufacturing considerations, and ideal applications of high durability composite epoxy CEM3 material, highlighting its role in extending the lifespan of electronic systems in challenging settings.

High Durability Composite Epoxy CEM3 Material retains the core structure of standard CEM3—epoxy resin combined with glass fiber reinforcement—but incorporates modifications to enhance its resistance to wear, environmental stress, and operational degradation. Unlike standard CEM3, which is optimized for general-purpose use, high durability variants are engineered with three key objectives: to withstand prolonged exposure to harsh conditions, maintain mechanical integrity under stress, and preserve electrical performance over extended lifespans.

At its core, this material retains the hybrid reinforcement structure of CEM3: a non-woven glass fiber mat core with woven glass fabric layers. However, advancements in resin formulation, fiber treatment, and additive integration distinguish it. These modifications target critical failure points in standard CEM3, such as delamination under thermal cycling, moisture absorption, and mechanical fatigue, making it suitable for applications where downtime or replacement costs are prohibitive.

The durability of high durability composite epoxy CEM3 material stems from deliberate improvements in its constituent components, each addressing specific failure mechanisms:

High durability CEM3 uses modified epoxy resins with cross-linking agents that form stronger chemical bonds during curing. This enhances resistance to thermal oxidation—a common cause of resin degradation in high-temperature environments. The resins also exhibit lower moisture absorption compared to standard CEM3 formulations, reducing the risk of swelling, delamination, or electrical insulation breakdown in humid conditions.

The glass fibers in high durability CEM3 undergo surface treatments (such as silane coatings) to improve adhesion to the epoxy matrix. This stronger bond minimizes fiber-matrix separation under mechanical stress, such as vibration or impact, which can weaken the substrate and lead to electrical failures. Additionally, the non-woven core mat may feature higher fiber density, enhancing structural integrity without compromising processability.

While retaining UL94 V-0 flame resistance, high durability CEM3 uses flame retardant additives that are more chemically stable. Traditional brominated additives can degrade over time in the presence of heat or UV radiation, reducing their effectiveness. High durability variants often incorporate phosphorus-based or nitrogen-based retardants, which maintain their flame-suppressant properties longer, ensuring safety compliance throughout the product’s lifecycle.

To protect against chemical exposure—common in industrial or automotive environments—high durability CEM3 may include corrosion inhibitors. These additives form a protective barrier around copper traces and glass fibers, preventing degradation from oils, solvents, or atmospheric pollutants that can compromise conductivity or mechanical strength.

High durability composite epoxy CEM3 material distinguishes itself through enhanced performance in key areas that directly impact lifespan and reliability:

Standard CEM3 can experience delamination when subjected to repeated temperature fluctuations, as the epoxy resin and glass fibers expand and contract at slightly different rates. High durability variants mitigate this through resin formulations with a more closely matched coefficient of thermal expansion (CTE) to the glass fibers, reducing internal stress. This allows the material to withstand hundreds of thermal cycles (from -40°C to 125°C) without losing structural integrity—critical for outdoor electronics or automotive systems.

The strengthened fiber-matrix bond in high durability CEM3 improves flexural strength and impact resistance. This makes it more resistant to cracking or warping under mechanical stress, such as vibration in industrial machinery or accidental impacts in portable devices. Unlike standard CEM3, which may fail after prolonged vibration, high durability variants maintain their shape and component mounting stability, reducing the risk of solder joint fatigue or trace damage.

By minimizing moisture absorption, high durability CEM3 resists swelling and maintains electrical insulation properties in humid environments—such as coastal regions or industrial facilities with high humidity. Its chemical resistance also ensures performance in settings where exposure to oils, coolants, or cleaning agents is common, such as factory floors or vehicle engine bays (for non-underhood components).

For outdoor applications, high durability CEM3 often includes UV stabilizers in the epoxy resin. These additives prevent photodegradation, which can cause the resin to become brittle and crack when exposed to sunlight over time. This makes it suitable for solar panel junction boxes, outdoor sensors, or telecommunications equipment mounted in exposed locations.

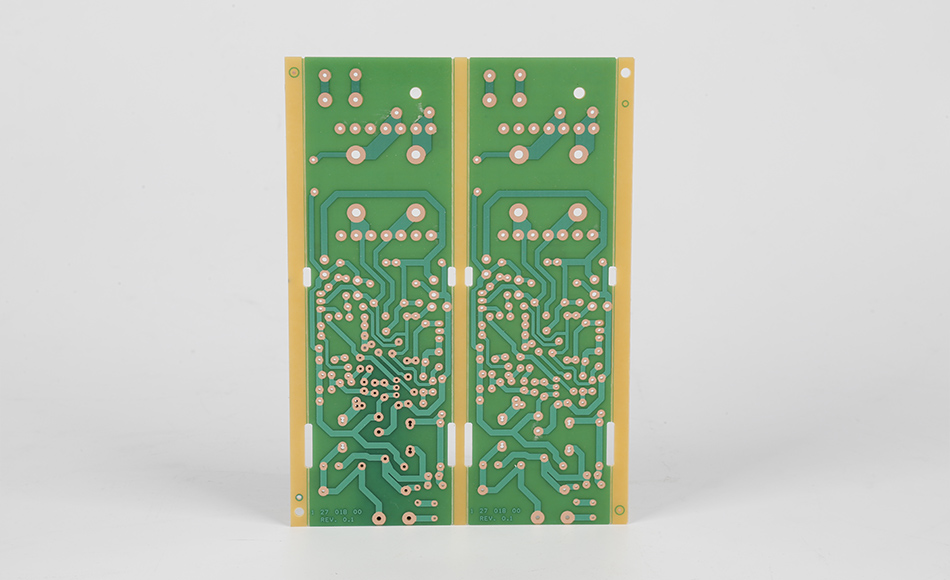

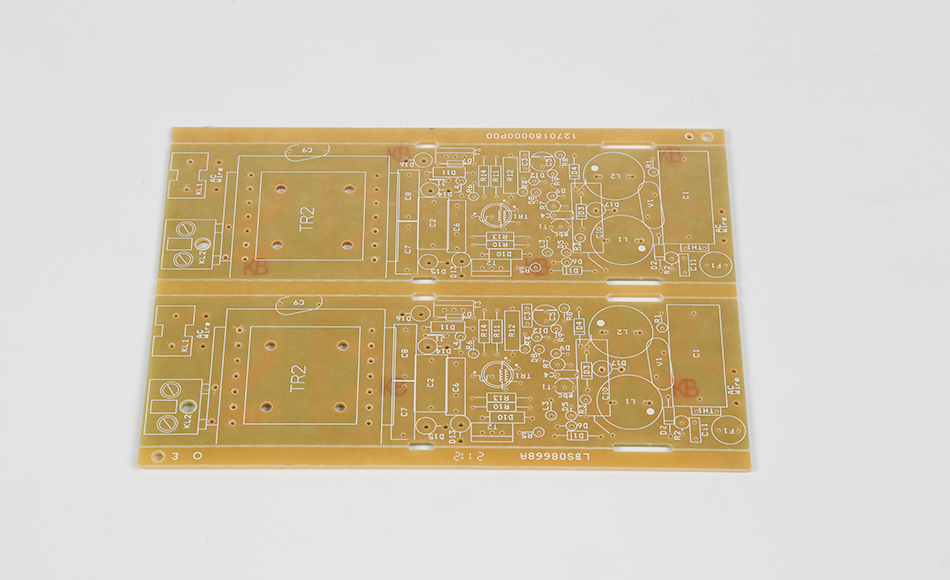

Producing high durability composite epoxy CEM3 material requires adjustments to standard CEM3 manufacturing processes to preserve its enhanced properties:

The modified epoxy resins in high durability CEM3 require precise curing parameters (temperature, pressure, and time) to ensure full cross-linking of the polymer chains. Deviations from the optimal curing profile can reduce the resin’s strength or thermal resistance, so manufacturers use advanced ovens with real-time monitoring to maintain consistency.

To maximize the effectiveness of surface-treated fibers, the impregnation process (where epoxy resin is applied to glass mats) must ensure uniform coverage. High durability CEM3 often uses vacuum-assisted resin transfer molding (VARTM) to eliminate air bubbles and ensure every fiber is fully coated, enhancing the fiber-matrix bond.

Unlike standard CEM3, which may undergo basic quality checks, high durability variants require rigorous testing to validate their resilience. This includes thermal cycling tests, humidity testing (85°C/85% RH for 1,000 hours), and mechanical stress tests (vibration, impact) to ensure they meet durability claims. These tests add production time but are critical for applications where reliability is non-negotiable.

Despite its enhancements, high durability CEM3 remains compatible with standard PCB manufacturing techniques, such as drilling, etching, and solder mask application. This ensures manufacturers do not need specialized equipment to process it, keeping production costs competitive compared to high-performance substrates like FR4.

High durability composite epoxy CEM3 material is engineered for applications where longevity and resistance to harsh conditions are prioritized over extreme performance:

Factory automation equipment, such as programmable logic controllers (PLCs) and sensor modules, operates in environments with vibration, temperature fluctuations, and occasional chemical exposure. High durability CEM3 ensures these systems remain reliable for 10+ years, reducing maintenance downtime in production lines.

While underhood components require metal-core or high-temperature FR4 substrates, automotive interior systems (e.g., dashboard controls, seat sensors) and semi-exposed components (e.g., door modules) benefit from high durability CEM3. It withstands temperature swings from -40°C (cold starts) to 85°C (sun-heated cabins) and resists oils and cleaning agents, ensuring long-term functionality.

Solar panel junction boxes, weather stations, and outdoor LED lighting fixtures use high durability CEM3 to withstand UV exposure, rain, and temperature extremes. Its moisture resistance prevents corrosion of connections, while UV stability ensures the PCB remains structurally sound for the 20+ year lifespan typical of solar installations.

In marine environments, where saltwater spray and high humidity accelerate corrosion, high durability CEM3’s moisture and chemical resistance make it ideal for navigation equipment, fish finders, or boat communication systems. It resists salt-induced degradation, extending the service life of these often-expensive devices.

Certain medical devices, such as portable diagnostic tools or equipment used in sterilization environments (non-autoclave), require materials that withstand frequent cleaning with disinfectants. High durability CEM3’s chemical resistance and longevity ensure these devices remain reliable through years of daily use and cleaning cycles.

High durability composite epoxy CEM3 material occupies a unique position in the PCB substrate market, offering a balance of resilience and cost that distinguishes it from alternatives:

High durability CEM3 provides 2–3 times the service life in harsh environments, making it worthwhile for applications where replacement is costly or disruptive. While it commands a 10–15% price premium, this is often offset by reduced maintenance costs.

FR4 offers superior thermal and mechanical performance but at a 30–50% higher cost than high durability CEM3. For applications that do not require FR4’s extreme temperature resistance (above 150°C) or high-frequency performance, high durability CEM3 provides sufficient durability at a lower cost.

Metal-core substrates excel at heat dissipation but are heavier and more expensive than high durability CEM3. They are unnecessary for low-heat applications, where high durability CEM3 offers better value while still providing environmental resilience.

Polyimide substrates offer excellent high-temperature resistance but are significantly more expensive and less processable than high durability CEM3. They are reserved for extreme environments (e.g., aerospace), whereas high durability CEM3 serves most industrial and outdoor applications at a fraction of the cost.

As demand for longer-lasting electronics grows, high durability composite epoxy CEM3 material continues to evolve through targeted innovations:

Adding carbon nanotubes or graphene to the epoxy resin is being explored to further enhance mechanical strength and thermal conductivity. These nanomaterials can improve impact resistance and heat dissipation without increasing weight, expanding the material’s use in power-dense applications.

Research into self-healing epoxy formulations could enable high durability CEM3 to repair small cracks or delaminations caused by stress. This would further extend lifespan, particularly in remote or hard-to-maintain systems like offshore sensors.

Manufacturers are developing high durability CEM3 with recycled glass fibers and bio-based epoxy resins, reducing its environmental impact while maintaining durability. This aligns with global sustainability goals, making it attractive for eco-conscious industries like renewable energy.

High Durability Composite Epoxy CEM3 Material represents a strategic advancement in PCB substrates, offering enhanced resilience for applications where longevity and reliability are critical. By addressing the limitations of standard CEM3—through improved thermal cycling resistance, mechanical strength, and environmental tolerance—it fills a valuable niche between general-purpose materials and costly high-performance substrates. Its compatibility with standard manufacturing processes and competitive pricing make it accessible for a wide range of industries, from industrial automation to outdoor electronics. As technology demands longer product lifespans and greater resistance to harsh conditions, high durability CEM3 will continue to play a key role in ensuring electronic systems perform reliably throughout their intended lifecycle, reducing waste and maintenance costs in the process.

Related Articles

CEM3 PCB Material Guide for Cost-Effective Electronic Applications

CEM3 PCB: The Versatile Workhorse of Modern Electronics Ecosystem

Thermal CEM3: Balancing Heat Management and Practicality in Electronics Substrates

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB