-

- PCB TYPE

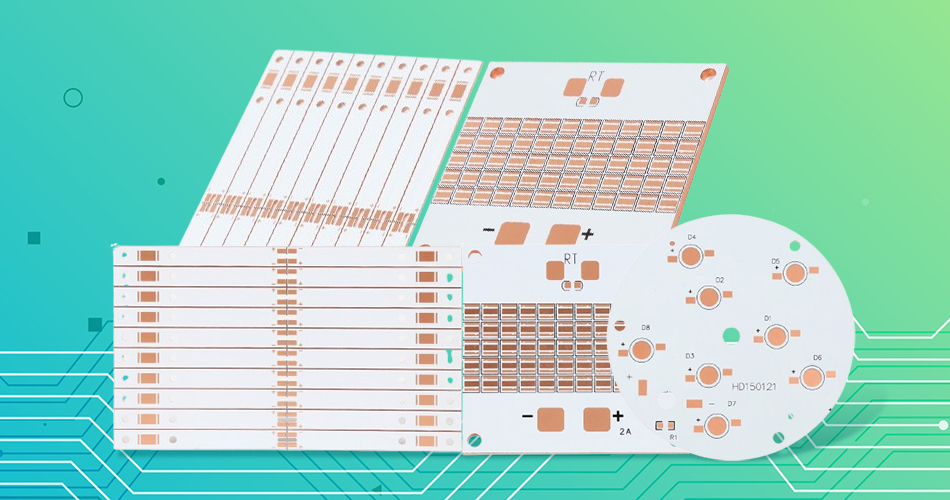

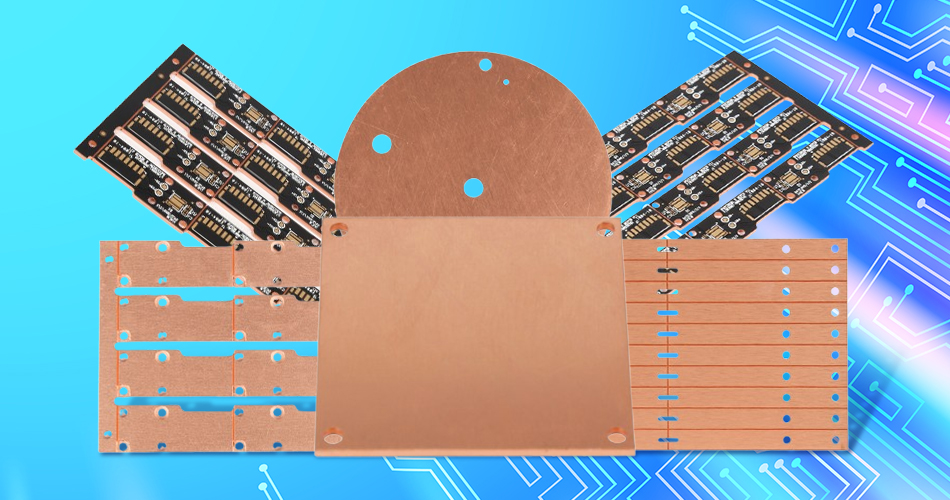

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Nov 14. 2025, 11:20:06

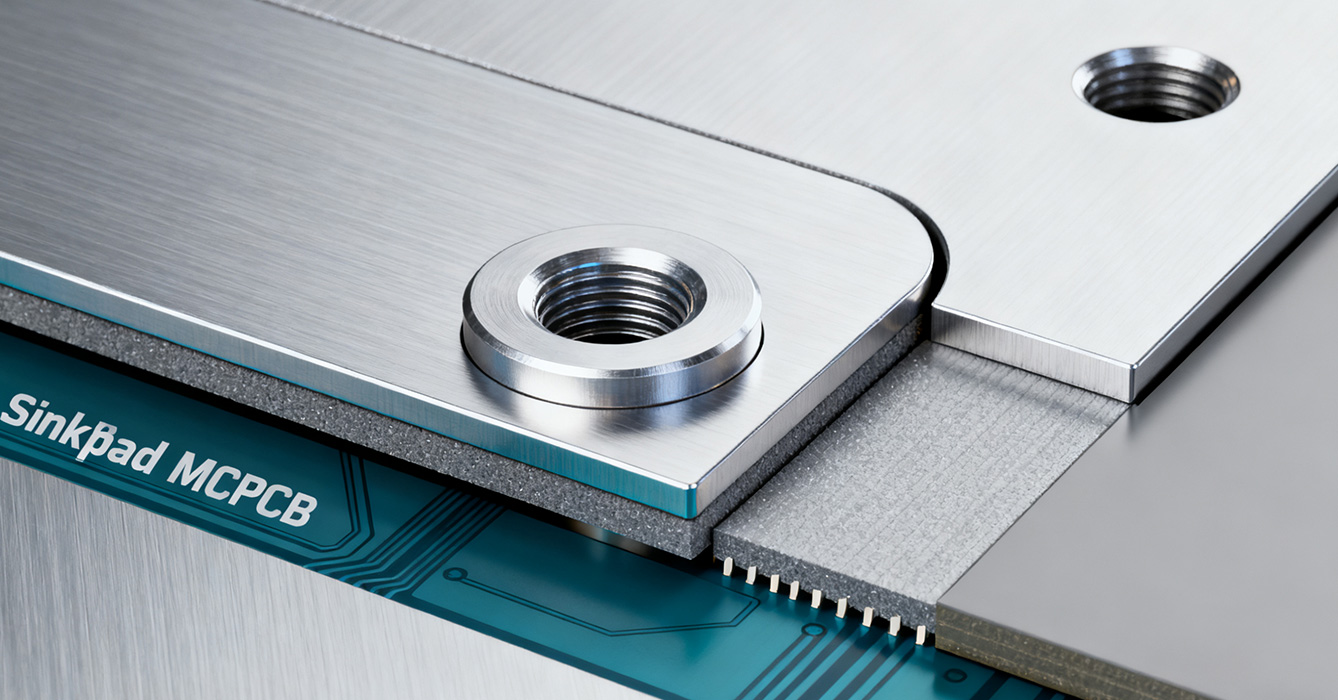

Countersink Holes for Sinkpad MCPCB (Metal-Core PCB) represents a specialized integration of precision mechanical design and thermal management, tailored to the unique advantages of metal-core substrates. Unlike standard MCPCBs where sinkpad mounting relies on flat surfaces (often leading to thermal gaps or misalignment), this innovation incorporates precision-engineered countersink holes directly into the MCPCB’s metal core—typically aluminum or copper. These holes are machined to exact specifications to accommodate high-power component mounting (e.g., high-flux LEDs, SiC power modules, and RF amplifiers) while maximizing thermal transfer between the component, sinkpad, and MCPCB’s metal core. For applications demanding the superior heat dissipation of MCPCBs plus tight mounting tolerances (such as automotive lighting, industrial power electronics, and aerospace systems), Countersink Holes for Sinkpad MCPCB resolves the tradeoff between thermal efficiency and mechanical stability. This article explores its MCPCB-specific design principles, technical synergies, targeted applications, manufacturing best practices, and future advancements.

The technology’s performance is rooted in three design pillars that leverage MCPCB’s metal-core advantage while enhancing precision:

Metal Core Compatibility: Countersink holes are machined to match the MCPCB’s metal core material—aluminum (for cost-effectiveness and thermal conductivity) or copper (for ultra-high heat dissipation). Aluminum cores use standard CNC machining, while copper cores require specialized tooling to avoid burring and maintain tolerance.

Tolerance Alignment: Countersinks adhere to MCPCB-specific tolerances (e.g., angular accuracy of 82° ±1°, depth precision of ±0.01mm) to align with component packaging. This ensures the component’s thermal base sits flush with the sinkpad, eliminating air gaps that undermine MCPCB’s inherent thermal conductivity.

Uninterrupted Heat Path: Countersink holes are integrated into the sinkpad, which is bonded directly to the MCPCB’s metal core. Heat flows from the component through the sinkpad, into the metal core, and across the entire MCPCB surface—leveraging the core’s large thermal mass to dissipate heat efficiently. This reduces component junction temperatures by 20–30% compared to flat-mount sinkpad MCPCBs.

Gap-Free Thermal Interface: The countersink’s tapered walls and flat bottom create a contiguous contact surface between the component and sinkpad. Unlike flat designs, this eliminates micro-gaps that trap air, enhancing thermal transfer between the component and MCPCB’s metal core by 30–40%.

Load Distribution on Metal Core: The countersink’s geometry distributes mounting forces (e.g., screw torque, thermal expansion) across the MCPCB’s rigid metal core. This prevents warping or delamination of the dielectric layer (between metal core and circuit layer), a common failure point in MCPCBs under mechanical stress.

Vibration Resistance: For high-vibration environments (e.g., automotive or industrial settings), countersink holes secure components tightly to the MCPCB’s metal core, reducing movement and solder joint fatigue. This extends assembly lifespan by 35–45% compared to non-countersunk sinkpad MCPCBs.

Countersink Holes for Sinkpad MCPCB amplifies MCPCB’s thermal benefits with four precision-driven advantages:

MCPCBs are valued for their high thermal conductivity, but flat-mount sinkpads create gaps that limit heat flow. Countersink holes eliminate these gaps, unlocking the full thermal potential of the metal core—critical for high-power components (e.g., 30W+ LEDs or 100A+ SiC modules) where efficient heat dissipation prevents thermal degradation.

Precision countersinks ensure component alignment variation of ±0.02mm or less in mass production. This consistency is vital for MCPCB-based systems (e.g., LED arrays or power module banks) where performance uniformity across multiple units is non-negotiable.

The metal core of MCPCBs provides mechanical rigidity, but improper component mounting can stress the dielectric layer. Countersink holes distribute loads evenly, protecting the dielectric and circuit layers from damage—extending MCPCB lifespan in harsh operating conditions (-40°C to 130°C).

Countersink holes recess component mounting features (e.g., screw heads or base plates) below the MCPCB surface, reducing overall assembly height by 15–25%. This complements MCPCB’s thin-profile design, making it ideal for compact applications like portable power tools, UAV electronics, or automotive headlight modules.

The technology excels in scenarios where MCPCB’s thermal advantages are paired with precision mounting needs:

Industrial high-bay lights, automotive headlights, and UV curing systems rely on MCPCBs for heat dissipation. Countersink holes ensure LED arrays are mounted flush with the sinkpad, maximizing thermal transfer and reducing luminous flux decay by 40% over 50,000 hours.

SiC and IGBT power modules for motor drives, inverters, and renewable energy systems use MCPCBs to handle high currents. Countersink holes provide gap-free contact between modules and the MCPCB’s metal core, enabling higher power density and complying with industrial temperature standards.

EV traction inverters, battery management systems (BMS), and onboard chargers use MCPCBs for thermal resilience. Countersink holes secure components to the MCPCB’s metal core, resisting vibration and temperature cycles while supporting 800V EV architectures.

Satellite power modules and drone electronics require lightweight, high-thermal-performance PCBs. MCPCBs with countersink holes offer the ideal balance: aluminum cores reduce weight, while countersinks ensure precise component mounting and reliable heat dissipation in vacuum or extreme temperature environments.

To optimize performance, manufacturers must address MCPCB-specific challenges:

Aluminum MCPCBs: Use high-speed steel (HSS) or carbide tools for countersinking, ensuring clean cuts without burring.

Copper MCPCBs: Employ diamond-coated tools to handle copper’s hardness, maintaining tolerance and surface finish.

Countersink machining must stop at the sinkpad (metal core) to avoid damaging the dielectric layer between the core and circuit layer. Use depth-controlled CNC machines to ensure precision and prevent dielectric delamination.

Use optical coordinate measuring machines (CMMs) to verify countersink dimensions (angle, depth, diameter) against MCPCB and component specifications.

Conduct thermal resistance testing to confirm gap-free contact between components and the MCPCB’s metal core.

The evolution of Countersink Holes for Sinkpad MCPCB aligns with MCPCB technology trends:

Hybrid Metal Core Countersinks: Copper-aluminum composite MCPCBs with countersink holes will combine copper’s thermal conductivity with aluminum’s machinability and cost-effectiveness.

Micro-Countersinks for Miniaturized MCPCBs: For wearable or micro-electronics, micro-countersinks (≤0.8mm diameter) will enable precise mounting of ultra-small high-power components on miniaturized MCPCBs.

AI-Optimized Countersink Layouts: Machine learning algorithms will analyze MCPCB heat maps and component footprints to optimize countersink positions, maximizing thermal efficiency and mounting stability.

Countersink Holes for Sinkpad MCPCB elevates the performance of metal-core PCBs by merging their inherent thermal advantages with precision mounting. By eliminating thermal gaps, ensuring consistent alignment, and enhancing structural integrity, this technology addresses the unmet needs of high-power, precision-constrained applications—from LED lighting to aerospace electronics. As MCPCBs continue to be the substrate of choice for heat-intensive electronics, countersink holes will remain a critical innovation, proving that the synergy between mechanical precision and thermal management is key to unlocking next-gen device performance.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB