-

- PCB TYPE

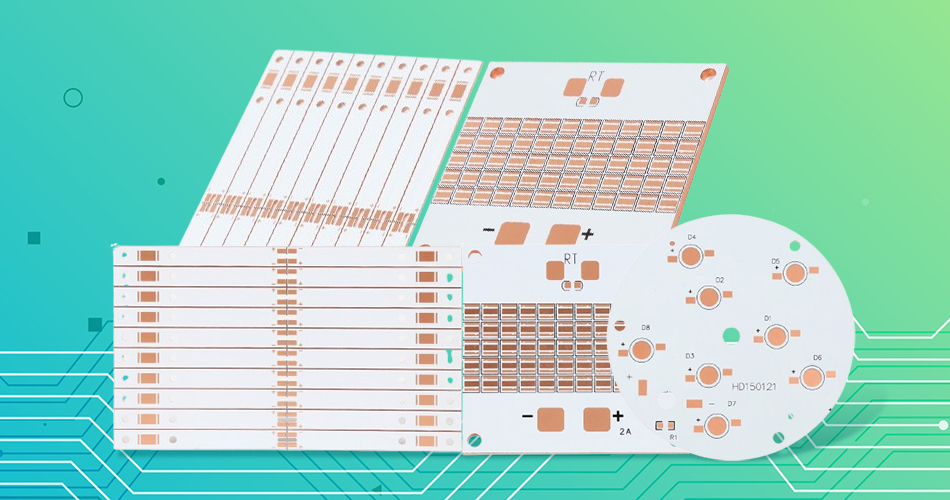

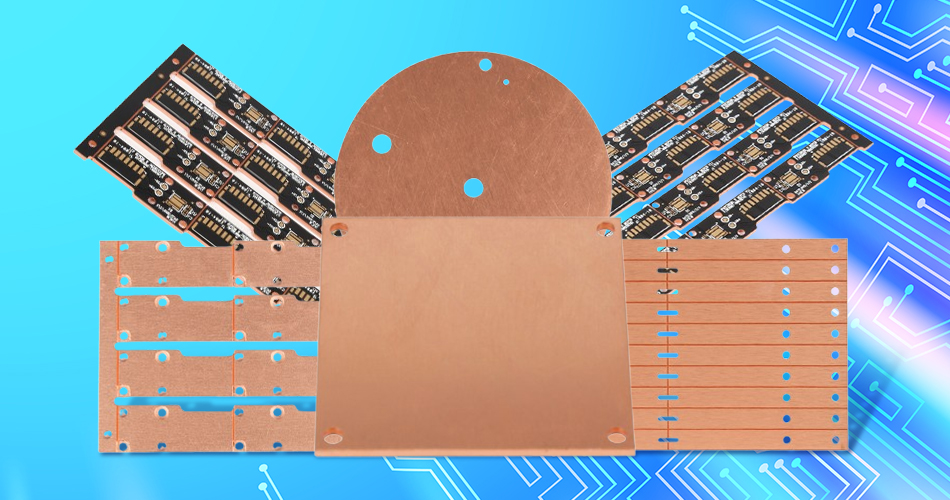

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Nov 14. 2025, 11:17:51

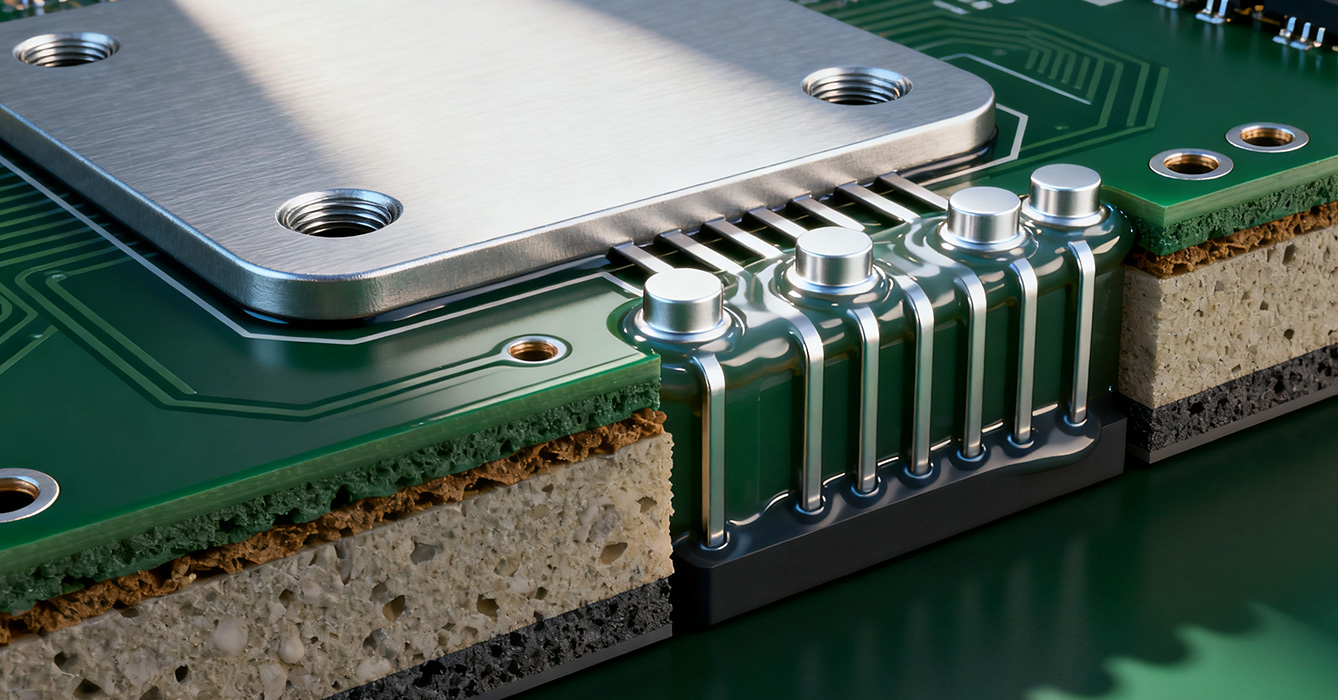

Precision Countersink Sinkpad PCB represents a specialized advancement in thermal management and mechanical integration, combining the heat-dissipating capabilities of sinkpad technology with the precision of countersunk mounting features. Unlike standard sinkpad PCBs where component attachment relies on flat surfaces (often leading to alignment gaps or uneven thermal contact), this innovative design incorporates precision-machined countersinks directly into the sinkpad layer. These countersinks—engineered for exact depth, diameter, and angular tolerance—ensure flush, gap-free mounting of high-power components (e.g., SiC MOSFETs, IGBT modules, and laser diodes) while optimizing thermal transfer. For applications demanding tight mechanical tolerances and reliable heat dissipation (such as aerospace electronics, industrial power modules, and medical devices), Precision Countersink Sinkpad PCB resolves the longstanding conflict between mounting accuracy and thermal efficiency. This article explores its core design attributes, technical advantages, targeted use cases, manufacturing considerations, and future innovations.

The technology’s performance hinges on three precision-focused design elements that integrate thermal and mechanical functionality:

Tolerance Control: Countersinks are machined to strict dimensional tolerances (e.g., coaxiality within ±0.02mm, angular accuracy of 82° or 90° ±1°) to match component packaging profiles. This ensures the component’s thermal base sits perfectly flush with the sinkpad, eliminating air gaps that increase thermal resistance.

Depth Optimization: The countersink depth is calibrated to avoid compromising PCB layer integrity—preserving the dielectric barrier between the sinkpad (metal core) and electrical layers while maximizing contact with the component’s heat spreader.

Gap-Free Interface: The countersink’s tapered walls and flat bottom create a contiguous contact surface between the component and sinkpad. Unlike flat-mount designs, this eliminates micro-gaps that trap air (a poor thermal conductor), reducing contact thermal resistance by 25–35%.

Thermal Path Continuity: The countersink is integrated directly into the sinkpad’s metal core (typically copper or aluminum alloy), ensuring heat flows unobstructed from the component to the sinkpad—then to external cooling systems (e.g., heat sinks or liquid cold plates).

Load Distribution: The countersink’s geometry distributes mechanical loads (e.g., from mounting screws, vibration, or thermal expansion) evenly across the sinkpad and PCB. This prevents localized stress on solder joints or component packaging, reducing failure risks in high-vibration environments.

Modular Compatibility: Precision countersinks support standardized component footprints, enabling seamless integration with off-the-shelf high-power modules. This simplifies design cycles and ensures interchangeability in mass production.

Precision Countersink Sinkpad PCB delivers four distinct benefits that address unmet needs in high-power electronics:

By eliminating air gaps through precision countersinking, the technology achieves contact thermal resistance values significantly lower than standard flat-mount sinkpads. This is critical for high-power components (e.g., 50W+ SiC devices) where even small resistance reductions prevent thermal throttling.

In batch production, precision countersinks ensure component alignment variation of less than ±0.03mm—far superior to flat-mount designs. This consistency reduces performance variability across assemblies, a key requirement for aerospace, medical, and industrial control systems.

The countersink’s integrated design strengthens the bond between the component and PCB, resisting vibration-induced loosening or thermal cycling fatigue. For automotive or aerospace applications (operating under 10–2000Hz vibration), this extends product lifespan by 30–40%.

Countersinks recess the component’s mounting features (e.g., screw heads or base plates) below the PCB surface, reducing overall assembly height by 15–20%. This is ideal for compact systems like portable industrial tools, UAV power modules, or medical handheld devices.

Precision Countersink Sinkpad PCB excels in scenarios where thermal efficiency, mounting precision, and mechanical stability are equally critical:

IGBT and SiC power modules for motor drives, inverters, and renewable energy converters rely on the technology’s gap-free thermal contact. Precision countersinks ensure uniform heat dissipation across module arrays, preventing hotspots and enabling higher power density.

Satellite payloads, drone power systems, and aircraft radar modules operate in extreme vibration and temperature cycles (-55°C to 125°C). The technology’s mechanical stability and thermal efficiency ensure reliable performance in these harsh environments, complying with MIL-STD-810 standards.

High-power medical lasers, diagnostic imaging equipment, and surgical tools require compact, precise thermal management. Precision Countersink Sinkpad PCBs reduce assembly size while maintaining consistent heat dissipation—critical for patient safety and device reliability.

EV traction inverters and battery management systems (BMS) face high vibration, high current, and space constraints. The technology’s flush mounting and thermal efficiency support 800V EV architectures, enabling faster charging and extended driving ranges.

To maximize performance, engineers must address three key factors:

Match countersink dimensions (diameter, depth, angle) to the component’s thermal base or mounting features. For example, a 90° countersink is ideal for flat-bottomed components, while a 82° angle suits conical mounting surfaces.

Select sinkpad materials (e.g., oxygen-free copper, aluminum alloy) that support precision countersinking without burring or material deformation. Harder alloys (e.g., copper-tungsten) may require specialized CNC machining tools to maintain tolerance.

Implement post-machining inspection (e.g., optical coordinate measuring machines, laser profilometers) to verify countersink dimensions. This ensures compliance with tolerance requirements and reduces assembly failures.

The evolution of Precision Countersink Sinkpad PCB is driven by miniaturization and automation:

Micro-Countersink Design: For ultra-small components (e.g., miniaturized laser diodes), micro-countersinks (≤1mm diameter) will enable precise mounting in microelectronics.

Automated Machining Integration: AI-driven CNC systems will optimize countersink tool paths in real time, reducing manufacturing time and improving tolerance consistency.

Hybrid Countersink-Thermal Paths: Countersinks with integrated micro-channels will combine mounting precision with enhanced heat dissipation for ultra-high-power applications.

Precision Countersink Sinkpad PCB redefines the intersection of thermal management and mechanical integration, addressing the critical needs of high-power, precision-constrained electronics. By leveraging precision countersinking to eliminate contact gaps, ensure mounting consistency, and enhance durability, it outperforms standard sinkpad PCBs in industries ranging from aerospace to EVs. As electronics continue to grow more power-dense and compact, this technology will remain a cornerstone of reliable, high-performance design—proving that precision in mounting is just as critical as efficiency in heat dissipation for next-gen devices.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB