-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Sep 09. 2025, 10:29:19

Printed Circuit Boards (PCBs) are the backbone of modern electronic devices, and their manufacturing involves a series of intricate processes. Among these, creating countersink holes is crucial for ensuring a secure fit for components. If you're looking into PCB fabrication in China, understanding the importance and process of countersink holes can be highly beneficial.

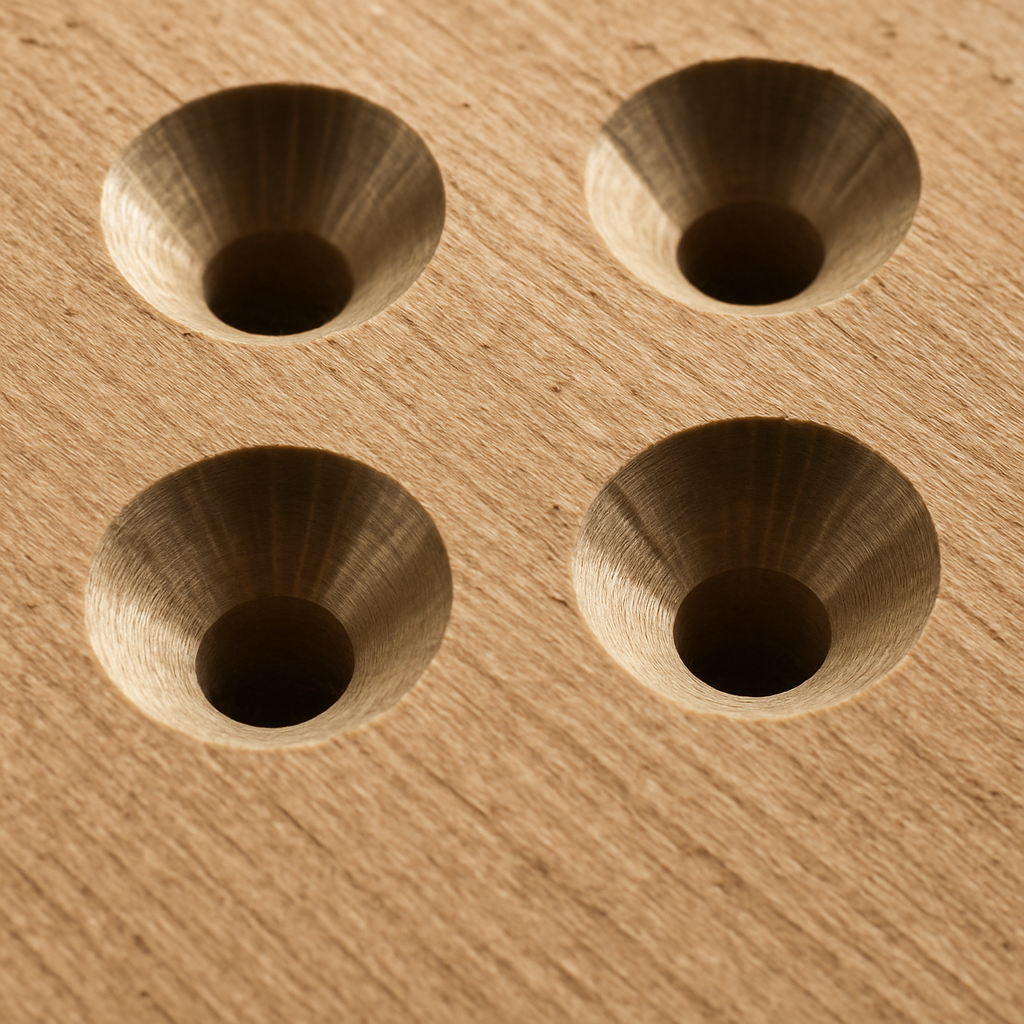

Countersink holes are specially designed holes that allow screws to sit flush with or below the surface of the PCB. This is critical for ensuring that components are securely attached without protruding elements that could interfere with other parts or cause damage.

Countersink holes play a vital role in ensuring the structural integrity and functionality of a PCB. They help in:

Securing Components Firmly: By allowing screws to sit flush, countersink holes prevent components from shifting, which could lead to malfunction.

Preventing Short Circuits: A flush screw reduces the risk of accidental contact with other electrical components, minimizing the chance of short circuits.

Improving Aesthetics: A smooth surface without protruding screws is not only functional but also visually appealing, which is crucial for consumer electronics.

China is renowned for its advanced PCB manufacturing capabilities. The country's factories are equipped with state-of-the-art technology and offer competitive pricing, making them a preferred choice for many businesses worldwide.

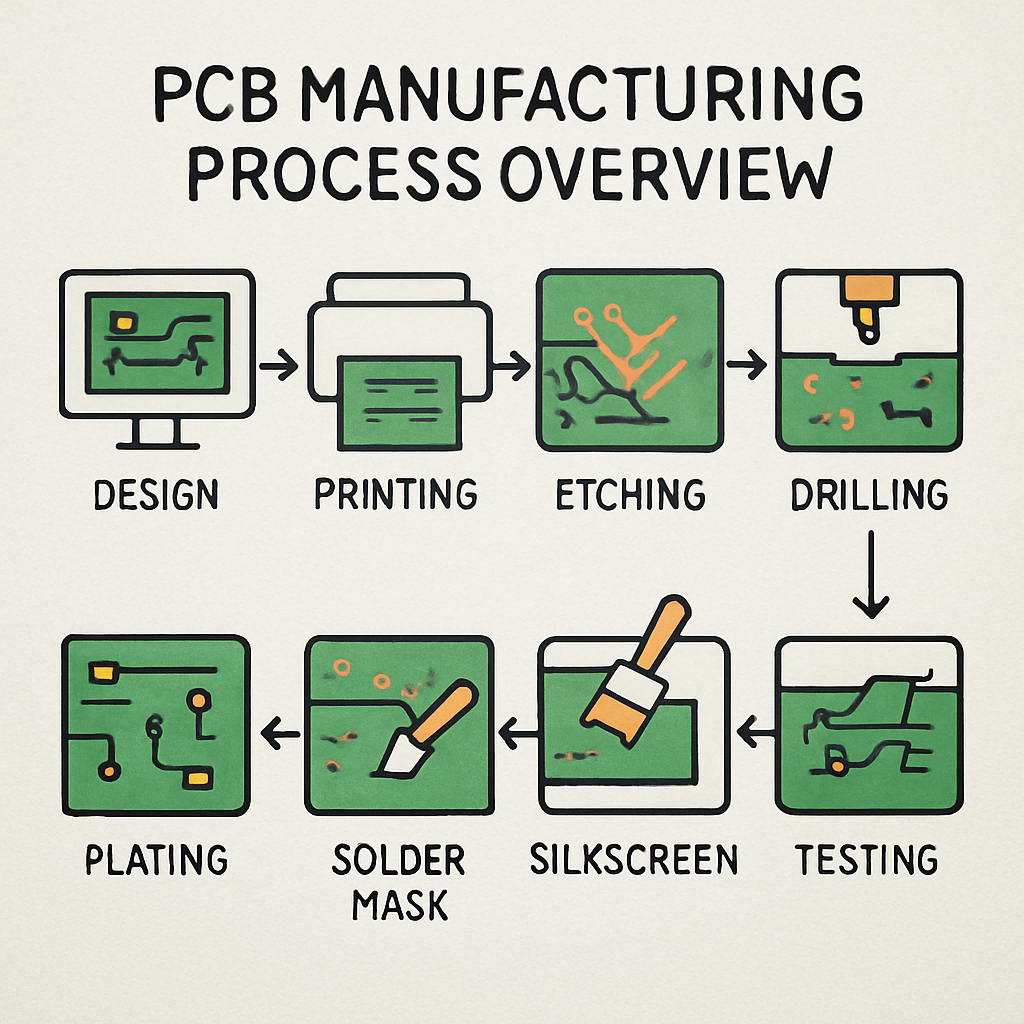

Design and Prototyping: The process begins with designing the PCB layout using specialized software. Once the design is finalized, a prototype is created to test functionality.

Material Selection: Depending on the application, different materials like FR4, polyimide, or metal cores are chosen for the PCB.

Layering and Lamination: The selected materials are layered and laminated to form the PCB's structure. This step is crucial for creating the board's electrical pathways.

Drilling and Plating: Holes, including countersink holes, are drilled into the board. These holes are then plated with conductive material to allow electricity to pass through different layers.

Etching and Solder Masking: Unwanted copper is etched away, leaving behind the desired circuit pattern. A solder mask is applied to protect the copper traces.

Component Placement and Soldering: Components are placed onto the board and soldered in place. This step requires precision to ensure all components function correctly.

Testing and Quality Control: Finished PCBs undergo rigorous testing to ensure they meet the required standards and specifications.

Cost Efficiency: Chinese manufacturers offer competitive pricing due to economies of scale and lower labor costs.

Advanced Technology: Factories in China are equipped with cutting-edge technology, ensuring high-quality production.

Fast Turnaround: With streamlined processes and efficient supply chains, Chinese manufacturers can offer quick production times.

Custom Solutions: Many manufacturers provide customization options to meet specific requirements, from unique layouts to specialized materials.

Selecting the right manufacturer is crucial for ensuring the quality and reliability of your PCBs. Here are some tips:

Choose a manufacturer with a proven track record in producing high-quality PCBs, particularly those that require countersink holes. Experienced manufacturers are more likely to understand the nuances of your project and deliver satisfactory results.

Ensure the manufacturer complies with international standards like ISO, IPC, and RoHS. These certifications indicate that the manufacturer adheres to quality and safety guidelines.

Investigate the manufacturer's production capabilities, including the types of PCBs they can produce, the materials they use, and their capacity to handle large orders.

Request Samples

Before committing to a large order, request samples to evaluate the quality of the manufacturer's work. This will give you a better understanding of their capabilities and the quality you can expect.

Effective communication is key to a successful partnership. Ensure that the manufacturer offers responsive customer support and is willing to collaborate closely throughout the production process.

Countersink holes are a critical component in PCB manufacturing, ensuring that your electronic devices function smoothly and efficiently. When sourcing PCBs from China, it's essential to understand the manufacturing process and select a manufacturer who can meet your specific needs. By doing so, you'll benefit from high-quality products, competitive pricing, and timely delivery, making your project a success.

Investing in a reliable PCB manufacturer in China can enhance your product's performance and contribute to your business's overall success. Whether you're a small business owner or a large corporation, understanding these key aspects of PCB fabrication will empower you to make informed decisions.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB