-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Sep 09. 2025, 10:31:45

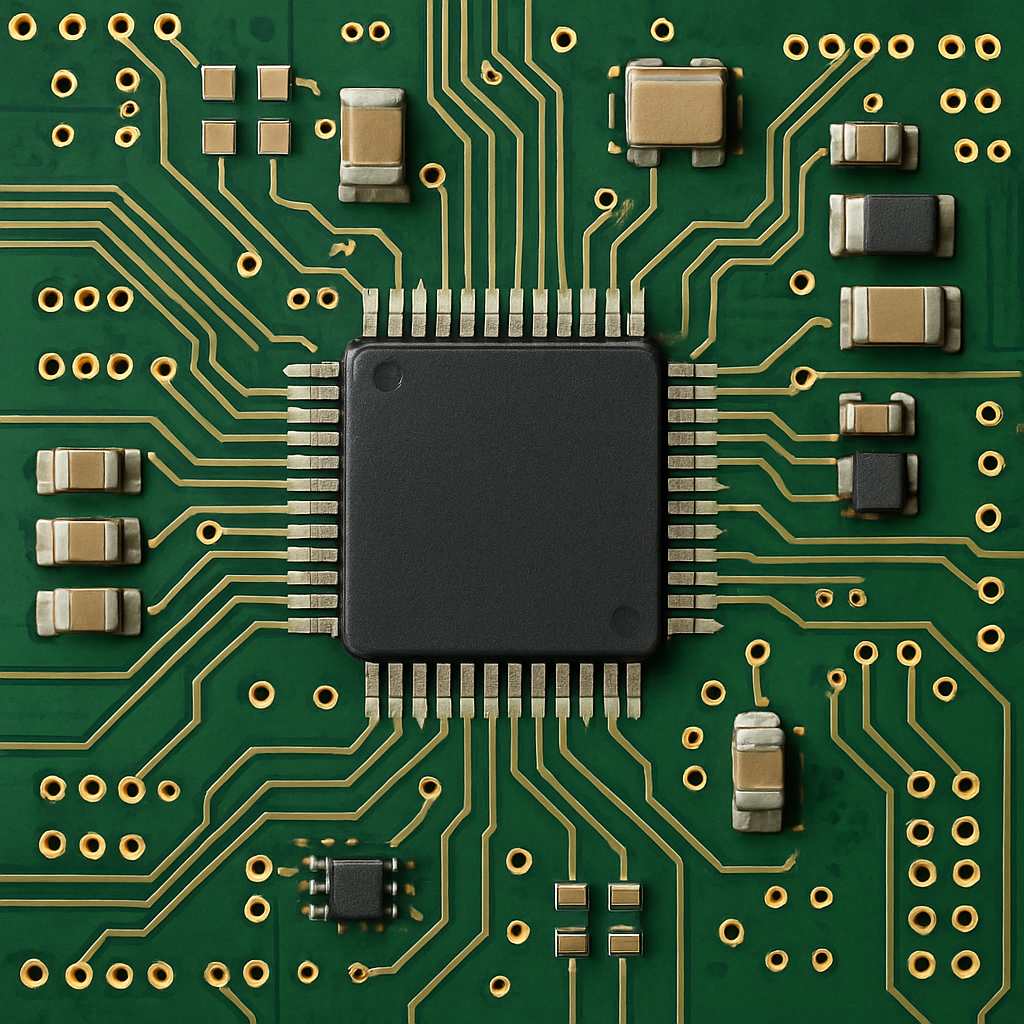

In the world of electronics, printed circuit boards (PCBs) are the unsung heroes. They form the backbone of most electronic devices, providing the pathways that connect various components. As technology continues to evolve, so does the need for advanced PCB manufacturing techniques. One such technique is the use of countersink holes in PCBs, a method that offers both aesthetic and functional benefits. In this article, we'll explore what countersink holes are, why they're used, and how a PCB manufacturer can incorporate them into your designs.

Countersink holes are a type of hole with a conical shape at the top, allowing screws to sit flush with or below the surface of the material. This design is particularly useful in PCB manufacturing, where space and surface flatness are often at a premium. By using countersink holes, manufacturers can ensure that screws do not protrude from the board, reducing the risk of interference with other components or housing.

Space Efficiency: In compact electronic devices, every millimeter counts. Countersink holes help save space by allowing screws to sit flush, which is crucial in tight-fitting assemblies.

Improved Aesthetics: A flat surface without protruding screws offers a cleaner, more professional appearance. This is especially important in consumer electronics where the look and feel can influence buying decisions.

Enhanced Structural Integrity: By allowing screws to sit flush, countersink holes help distribute stress more evenly across the board, enhancing the overall structural integrity of the PCB.

When it comes to integrating countersink holes into PCB designs, manufacturers must follow specific techniques to ensure precision and quality. Here are some of the key methods employed:

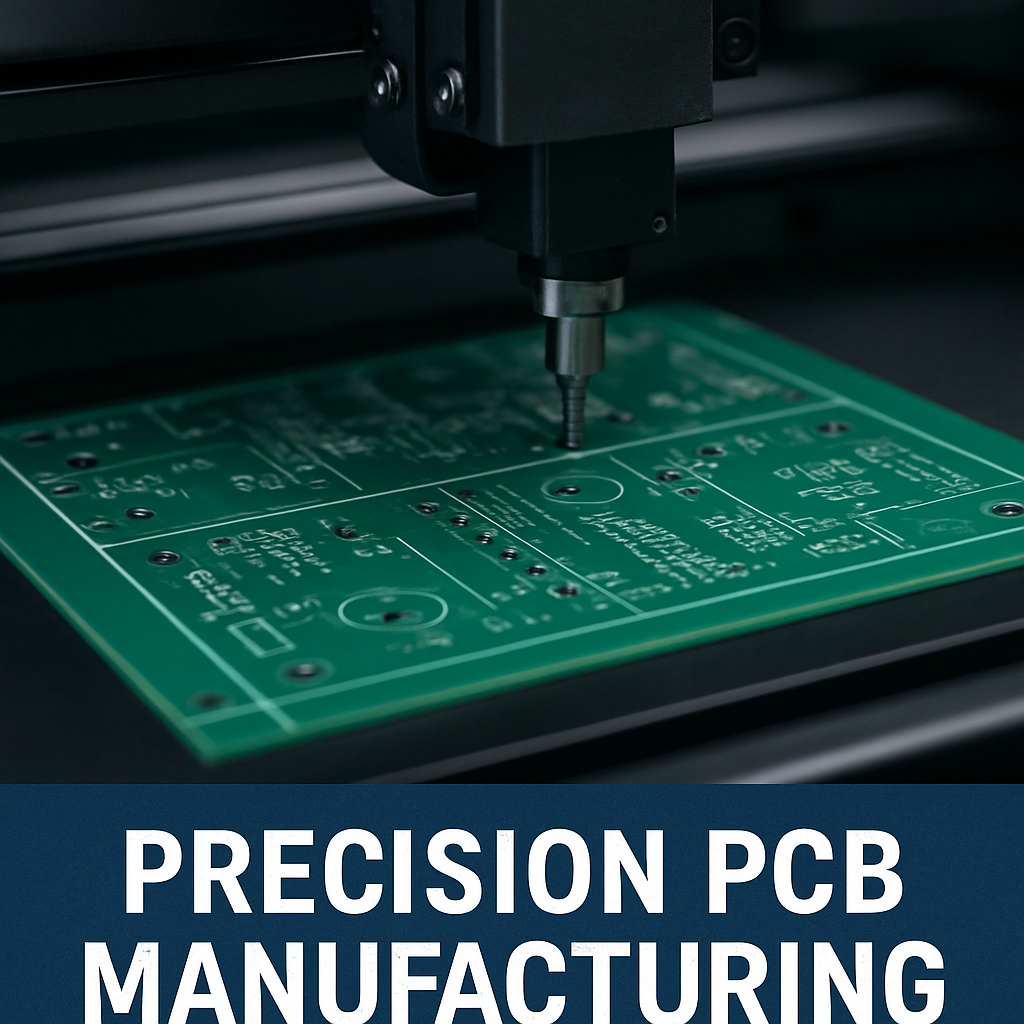

Precision drilling is crucial for creating accurate countersink holes. Manufacturers use advanced CNC machines to drill holes with exact specifications, ensuring that the conical shape is perfect for the intended screw size. This precision is vital to maintain the board's integrity and functionality.

The choice of material for the PCB can affect the countersinking process. Some materials may require specific tools or techniques to achieve the desired countersink without damaging the board. Manufacturers must carefully select materials that are compatible with countersinking to ensure optimal results.

For multi-layer PCBs, layer alignment is critical. Misaligned layers can lead to improper countersinking, affecting both the board's performance and appearance. Manufacturers use sophisticated alignment tools and techniques to ensure that each layer is perfectly positioned.

PCB assembly services play a crucial role in the integration of countersink holes. Here’s how:

During the assembly process, accurate component placement is essential. Countersink holes can influence where and how components are placed on the board. Manufacturers must ensure that components do not interfere with the countersink areas to maintain functionality and aesthetics.

Soldering components onto a PCB with countersink holes requires precision. The soldering process must be carefully controlled to prevent overflow into the countersink areas, which could compromise the flatness and integrity of the board.

Quality control is vital in ensuring that the PCB meets all design specifications, including those related to countersink holes. Manufacturers employ various testing and inspection methods to verify that the countersink holes are correctly implemented and that the board functions as intended.

Selecting the right PCB manufacturer is crucial for successfully incorporating countersink holes into your designs. Here are some factors to consider:

Look for a manufacturer with extensive experience in PCB manufacturing and a proven track record of incorporating advanced techniques like countersink holes. Experienced manufacturers are more likely to deliver high-quality boards that meet your specifications.

The technology and equipment used by the manufacturer can significantly impact the quality of the final product. Ensure that the manufacturer uses state-of-the-art CNC machines and other advanced tools to achieve precise countersinking.

Good customer support is essential for a smooth manufacturing process. Choose a manufacturer that offers excellent communication and is responsive to your needs and concerns throughout the project.

Countersink holes in PCBs offer numerous benefits, from improved aesthetics to enhanced structural integrity. By understanding the manufacturing techniques and choosing the right PCB manufacturer, you can effectively incorporate countersink holes into your designs, creating high-quality electronic products that stand out in the market.

Whether you're a small business owner looking to enhance your product offerings or a startup founder aiming to break into the electronics market, understanding the role of countersink holes in PCB manufacturing can give you a competitive edge. With the right expertise and manufacturing partner, you can achieve your design goals and deliver exceptional products to your customers.

Related Articles

Top PCB Manufacturers Near You | High-Quality PCB & PCBA Solutions

Manufacturing PCB: The Professional Guide to Industrial-Grade Fabrication and Sourcing

Reliable PCB Manufacturer in China | High-Quality PCB & PCBA Solutions

Reliable PCB Manufacturer for Global Electronics Production

Aluminum PCB Manufacturer | High Thermal Conductivity MC-PCB Boards

HA80 Aluminum PCB Specifications: Technical Foundations and Industrial Adaptability

GDM Aluminum Based CCL: A Versatile Foundation for Modern Electronics

Ventec Aluminum CCL Material Datasheet: A Paradigm of Thermal and Electrical Excellence

Boyu Aluminum CCL: Comprehensive Solutions for Advanced Electronics

Aluminium-Based CCL: Innovations in High-Performance Copper Clad Laminates

Aluminum PCB: Benefits and Applications for High-Power Electronics

Thermal Via Aluminum PCB Structure: Design Principles for Enhanced Heat Dissipation

Aluminum PCB: Benefits and Applications for High-Power Electronics

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB