-

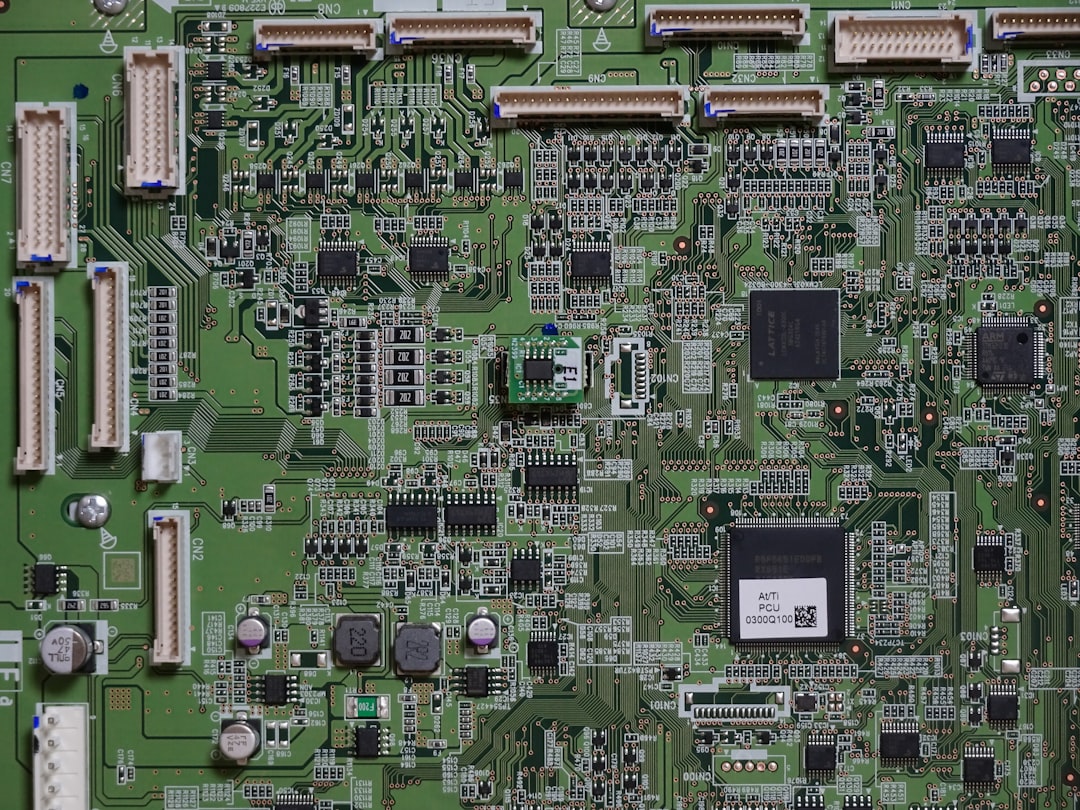

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Sep 09. 2025, 10:26:20

In the world of electronics, Printed Circuit Boards (PCBs) are fundamental components. They serve as the backbone for nearly all electronic devices, facilitating the connection between various components. As technology advances, the need for specialized and precise PCB manufacturing processes becomes more pronounced. One such specialized process is precision countersink PCB manufacturing.

A countersink hole in a PCB is a conical hole cut into the board to allow the head of a screw or bolt to sit flush with or below the surface of the board. This is crucial in applications where space is tight and the surface must be smooth. Precision countersink holes ensure mechanical stability and aesthetics of the final product, making them essential for high-performance and compact electronic devices.

Precision is key in countersink PCB manufacturing. Even a slight deviation can lead to misalignment, affecting the functionality and reliability of the electronic device. Precision countersink ensures that all components fit perfectly and the device operates without any hitches. This level of accuracy demands advanced machinery and skilled technicians.

The process begins with designing the PCB using specialized software. This design includes the layout of the circuits and the locati0n of the countersink holes. The design phase is critical as it determines the overall functionality and efficiency of the PCB.

Once the design is finalized, the next step is drilling the countersink holes. This requires precision drilling machines capable of creating holes with exact dimensions and angles. The depth and angle of the countersink must be precise to ensure the screw head sits flush with the surface.

After drilling, the PCB undergoes rigorous quality control and testing. This step ensures that all holes are correctly positioned and sized, and that the board meets all specified requirements. Testing also involves checking the electrical functionality of the PCB to ensure it operates as intended.

Precision countersink PCBs offer a sleek and professional appearance. The flush fit of screws and components not only improves the aesthetic appeal but also enhances the device's functionality by preventing interference with other components or the casing.

A PCB with precision countersink holes provides better mechanical stability. The flush-fitting screws distribute stress more evenly across the board, reducing the risk of damage during assembly and use.

In modern electronics, space is a premium. Precision countersink PCBs help save space by allowing components to be mounted closer together. This is especially important in compact devices like smartphones, tablets, and wearables.

Selecting the right manufacturer for precision countersink PCBs is crucial. Here are some factors to consider:

Look for manufacturers with a proven track record in precision PCB manufacturing. Experienced manufacturers are more likely to deliver high-quality products that meet your specifications.

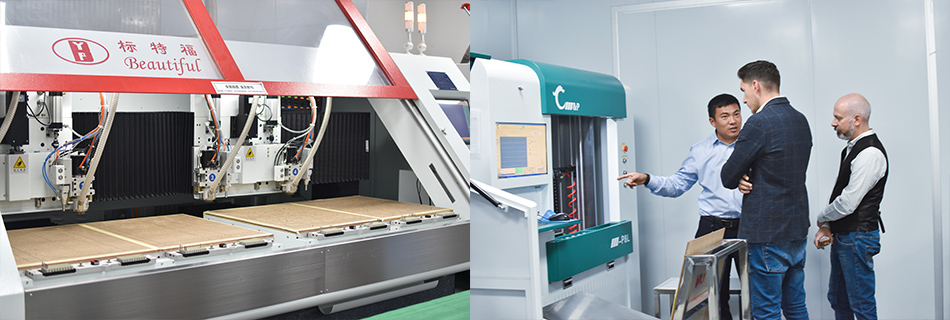

Ensure the manufacturer uses the latest technology and equipment. Advanced machinery ensures precision and efficiency in the manufacturing process.

A reputable manufacturer will have stringent quality assurance processes in place. This includes thorough testing and inspection of all PCBs before they are shipped.

Every project is unique, and your PCB manufacturer should offer customization options to meet your specific needs. This includes the ability to create custom designs and specifications.

Precision countersink PCBs are used in various applications across different industries:

In consumer electronics, space and aesthetics are paramount. Precision countersink PCBs are used in smartphones, laptops, and other devices where a sleek design is essential.

The automotive industry requires robust and reliable electronic components. Precision countersink PCBs are used in various automotive applications, including infotainment systems and engine control units.

In the medical field, precision and reliability are critical. Precision countersink PCBs are used in medical devices like imaging equipment and diagnostic tools, where accuracy is vital.

The aerospace and defense industries demand high-performance and durable components. Precision countersink PCBs are used in navigation systems, communication devices, and other critical applications.

Precision countersink PCB manufacturing is a specialized process that plays a vital role in modern electronics. By providing enhanced aesthetics, improved mechanical stability, and space optimization, precision countersink PCBs are essential for high-performance and compact electronic devices. When choosing a manufacturer, consider their experience, technology, and quality assurance processes to ensure you receive high-quality PCBs that meet your specific requirements. As technology continues to evolve, the demand for precision countersink PCBs will only increase, underscoring their importance in the electronics industry.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB