-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Oct 24. 2025, 18:09:16

When it comes to printed circuit board (PCB) assembly, attention to detail is crucial. One of the finer details that can significantly impact the performance and reliability of a PCB is the implementation of countersink holes. But what exactly are countersink holes, and why are they important in PCB assembly? This article will guide you through the countersinking process, its significance, and the best practices for incorporating countersink holes in your PCB assembly projects.

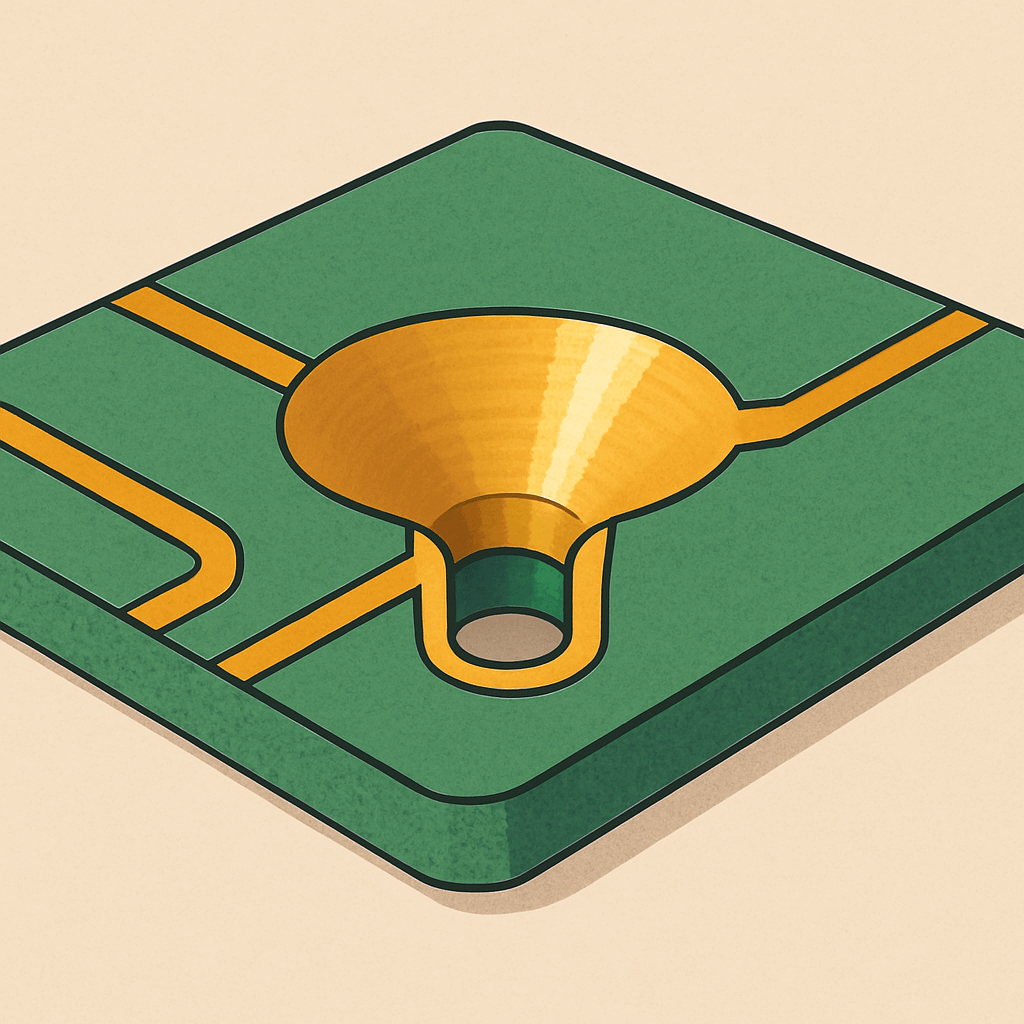

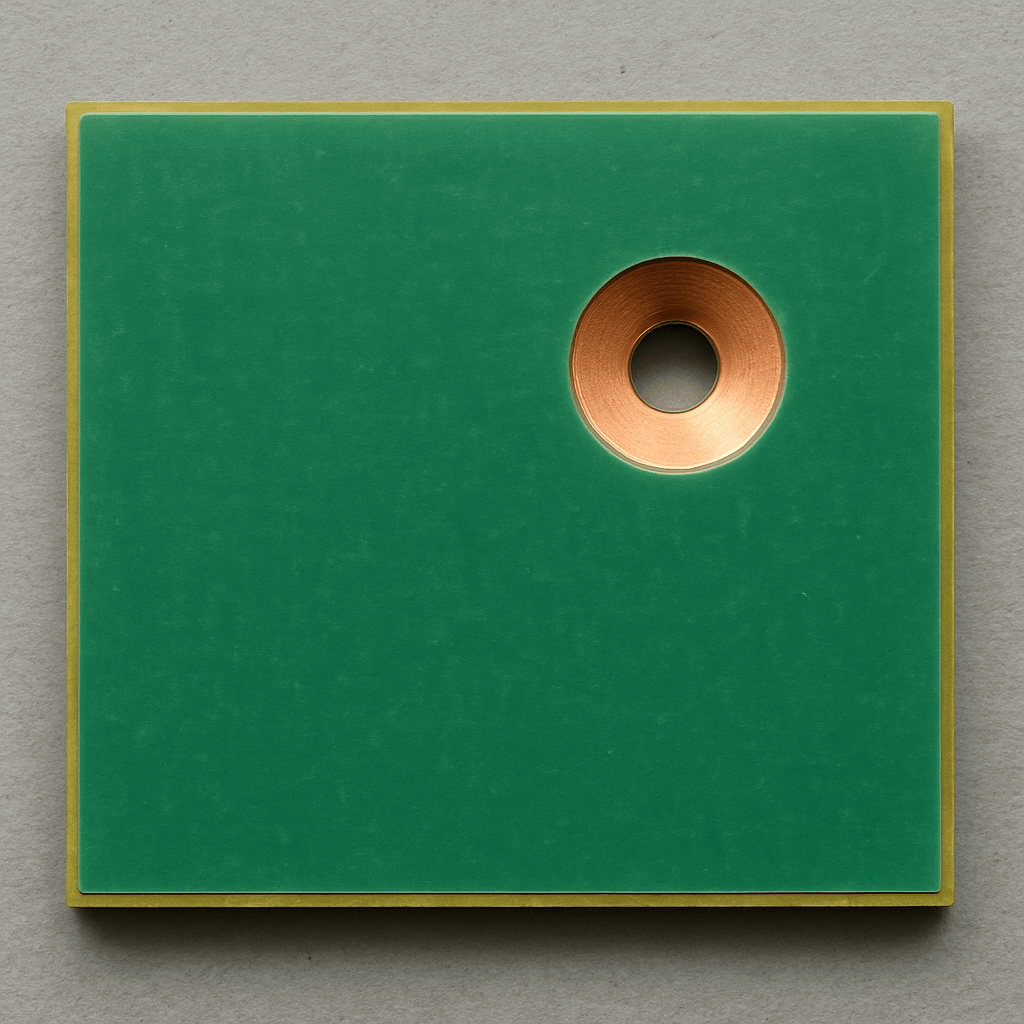

Countersink holes are conical holes cut into a PCB that allow the head of a screw or fastener to sit flush with or below the surface of the board. This is achieved by using a countersink drill bit, which creates a tapered surface. The primary purpose of these holes is to ensure that screws do not protrude from the board, which can be critical for both aesthetic and functional reasons.

The integration of countersink holes in PCB assembly is not just about aesthetics. It also plays a vital role in the mechanical stability and electrical performance of the board. Here’s why:

Mechanical Stability: By allowing screws to sit flush with the board surface, countersink holes reduce the risk of physical interference with other components or housing.

Space Efficiency: Especially in compact electronic devices, space is at a premium. Countersink holes help save space by ensuring that fasteners do not take up extra room.

Improved Aesthetics: A flush finish is often more visually appealing, which can be important for consumer-facing products.

Prevention of Short Circuits: Protruding screws can sometimes lead to unwanted electrical contact with other components, leading to short circuits. Countersink holes help mitigate this risk.

Implementing countersink holes in PCB assembly involves several steps. Here's a breakdown of the process:

The first step in the countersinking process is during the PCB design phase. Engineers must specify the size, locati0n, and number of countersink holes required. This involves using specialized PCB design software to ensure precision and accuracy.

Choosing the right PCB material is essential when planning for countersink holes. The material must be durable enough to withstand the countersinking process without compromising the board's integrity. Common materials include FR-4, which offers a good balance of strength and flexibility.

Drilling the countersink holes is a critical part of the process. It requires specialized equipment capable of creating the precise conical shape needed for the screws. This step must be performed with care to avoid damaging the board.

After drilling, the PCB must be inspected to ensure that the countersink holes are correctly placed and meet the required specifications. This is typically done using automated optical inspection (AOI) systems, which can quickly and accurately assess the quality of the holes.

Once the countersink holes are verified, the PCB can be assembled. This involves mounting components and securing them with the appropriate screws or fasteners.

To achieve the best results when incorporating countersink holes in PCB assembly, consider these best practices:

Precision in Design: Use advanced PCB design tools to accurately plan the locati0n and size of countersink holes.

Quality Drilling Equipment: Invest in high-quality drilling equipment to ensure precision and avoid damage to the PCB.

Thorough Inspection: Implement a rigorous inspection process to confirm the quality and accuracy of the countersink holes.

Material Compatibility: Ensure that the PCB material is compatible with the countersinking process to prevent cracks or other damage.

Proper Fasteners: Use screws or fasteners that are specifically designed for use with countersink holes to ensure a secure fit.

Despite careful planning, challenges can arise during the countersinking process. Here are some common issues and their solutions:

Misalignment: If countersink holes are misaligned, it can lead to assembly issues. This can be avoided by double-checking design files and using precision drilling equipment.

Material Cracking: Cracking can occur if the PCB material is not suitable for countersinking. Choose materials with the appropriate hardness and flexibility.

Inconsistent Hole Depth: Variations in hole depth can affect the fit of screws. Regularly calibrate drilling equipment and conduct thorough inspections to maintain consistency.

Countersink holes are an essential aspect of PCB assembly that can significantly impact the functionality and reliability of a circuit board. By understanding the countersinking process and adhering to best practices, you can ensure that your PCBs are assembled with precision and care. Whether you are a seasoned engineer or a newcomer to PCB assembly, mastering the art of countersink holes will enhance your projects and contribute to the success of your electronic devices.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB